Waterproof and corrosion-resistant rubber material for power line jacket of marine transportation vehicle and preparation method of waterproof and corrosion-resistant rubber material

A technology for marine transportation and power lines, applied in rubber insulators, circuits, electrical components, etc., can solve problems such as water resistance and corrosion resistance that cannot meet the needs of the market, improve thermal stability and chemical stability, and the scope of application Wide, improve the effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

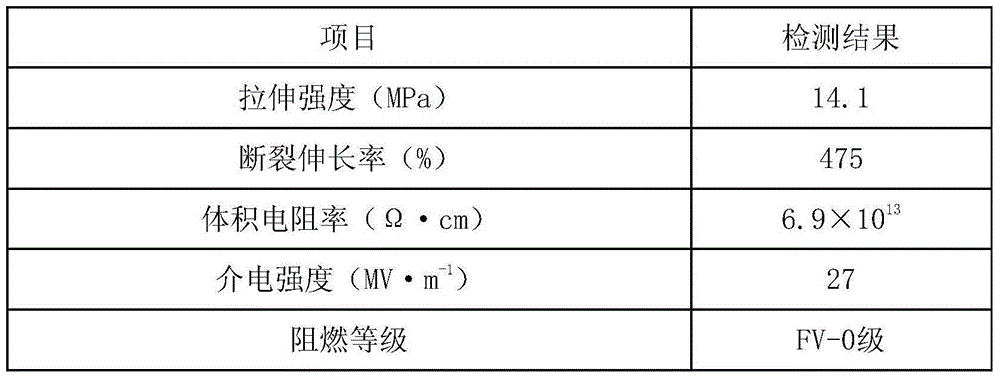

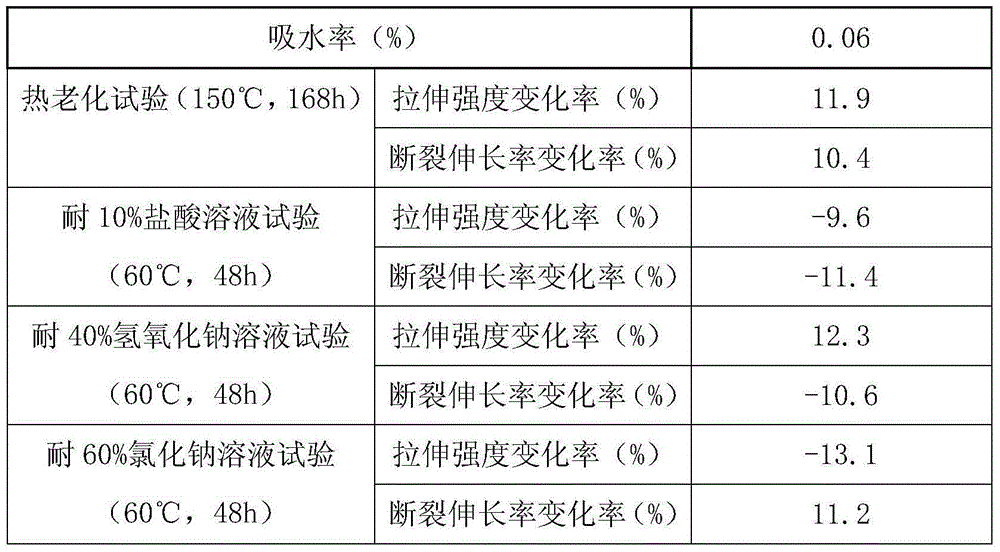

[0014] A water-resistant and corrosion-resistant rubber material for the outer sheath of the power cord of a marine vehicle, which is made of the following raw materials in weight (kg): tetrapropylene fluororubber 35, butyl rubber 20, light burning powder 7, vaseline 5, transformer No. 10 Oil 7, carboxyl-terminated liquid polybutadiene rubber 12, channel black 25, accelerator MBT2.5, accelerator OTOS1.5, low molecular weight polybutene 5, zinc stearate 2.5, diabase powder 12, Calcium rosinate 4, hydrophobic fumed silica 12, triethylenetetramine 3.5, bromomethyl-p-tert-octylphenol formaldehyde resin 5, accelerator PX2.5, accelerator DPTT1.5, antioxidant 4010NA1, antioxidant BLE1 .5. Glyceryl tristearate 6. Flame-retardant granules 16;

[0015] The preparation method of the flame retardant particles is as follows: a, take the raw materials of the following weight (kg): colemanite 27, brucite 20, boehmite 17, expanded graphite 12, basic sodium aluminum carbonate 10, basic Magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com