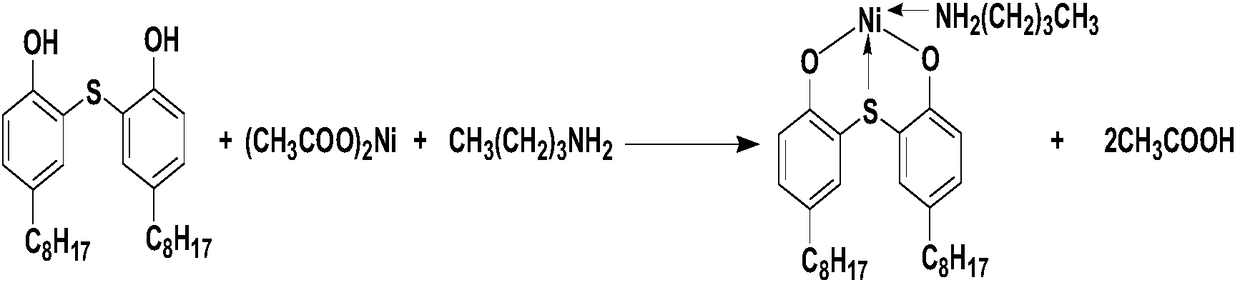

Preparation method for 2,2'-thiobis(4-tert-octylphenolato)-n-butylamine nickel(ii)

A technology of tert-octylphenol and n-butylamine nickel is applied in the field of preparation of 2,2'-thiobis-n-butylamine nickel, and can solve the problems of unstable product quality, large reaction fluctuation, large numerical value change, etc. To achieve the effect of improving reaction stability, avoiding by-products, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

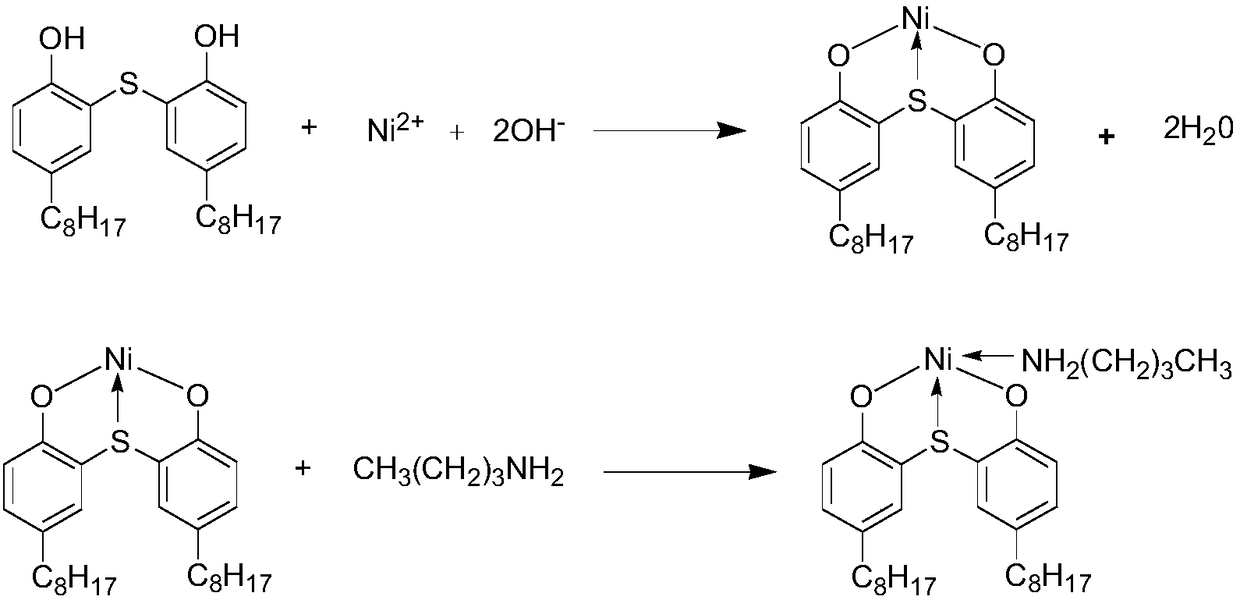

Method used

Image

Examples

Embodiment 1

[0033] Pour 900L of toluene, 450L of N,N-dimethylformamide, and 400L of water into a 5000L reactor, turn on the stirring, add 360kg of 2,2′-thiobis-p-tert-octylphenol, 193.6kg of hexahydrate and chloride nickel. Heat to 70°C, dissolve 32.5kg of sodium hydroxide in 200kg of water, add it from the high-level tank at an even speed within 3 hours, and keep it for 5 hours after the addition. At that time, stop stirring and let stand for 20 minutes, then divide and remove the lower aqueous phase. Add 59.5kg of n-butylamine to the organic phase, and stir at 50-80°C for 2 hours. The reaction solution was distilled to remove the solvent, dried and pulverized to obtain a light green powder product with a yield of 95.4% and a purity of 99.3%.

Embodiment 2

[0035] Pour 900L of petroleum ether, 450L of propanol, and 400L of water into the reactor, turn on the stirring, and add 630kg of 2,2′-thiobis-p-tert-octylphenol, 508.2kg of hexahydrate and nickel chloride. Heat to 70°C, dissolve 125 kg of sodium hydroxide in 200 kg of water, add it from the elevated tank at an even speed within 3 hours, and keep it for 5 hours after adding. At that time, stop stirring and let stand for 20 minutes, then divide and remove the lower aqueous phase. Add 104 kg of n-butylamine to the organic phase, and stir for 2 hours at 50-80°C. The reaction solution was distilled to remove the solvent, dried and pulverized to obtain a light green powder product with a yield of 95.6% and a purity of 99.2%.

Embodiment 3

[0037] Pour 900L of toluene, 300L of N-methylpyrrolidone, and 300L of water into the reactor, turn on the stirring, and add 495 kg of 2,2′-thiobis-p-tert-octylphenol, 332 kg of hexahydrate and nickel chloride. Heat to 70°C, dissolve 89.6kg of sodium hydroxide in 200kg of water, add it from the elevated tank at an even speed within 3 hours, and keep it for 5 hours after adding. At that time, stop stirring and let stand for 20 minutes, then divide and remove the lower aqueous phase. Add 84.2kg of n-butylamine to the organic phase, and stir at 50-80°C for 2 hours. The reaction solution was distilled to remove the solvent, dried and pulverized to obtain a light green powder product with a yield of 96.1% and a purity of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com