Method for preparing rubber tackifier p-tert-octylphenol formaldehyde resin

A technology of tert-octylphenol and formaldehyde resin, which is applied in the field of organic chemistry to achieve the effects of reducing preparation costs, promoting and applying prospects, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation method of rubber tackifier p-tertoctylphenol formaldehyde resin

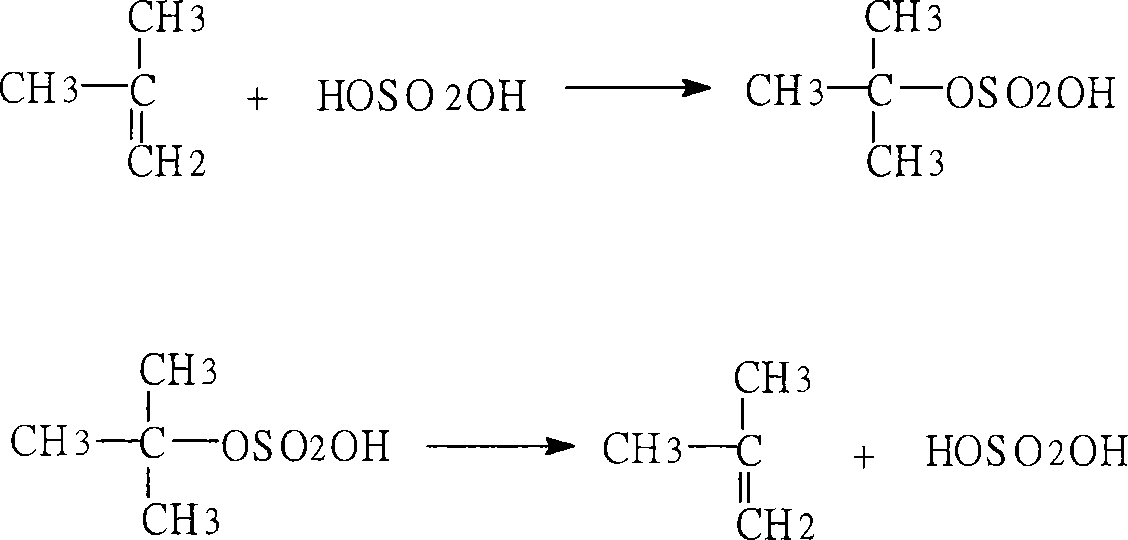

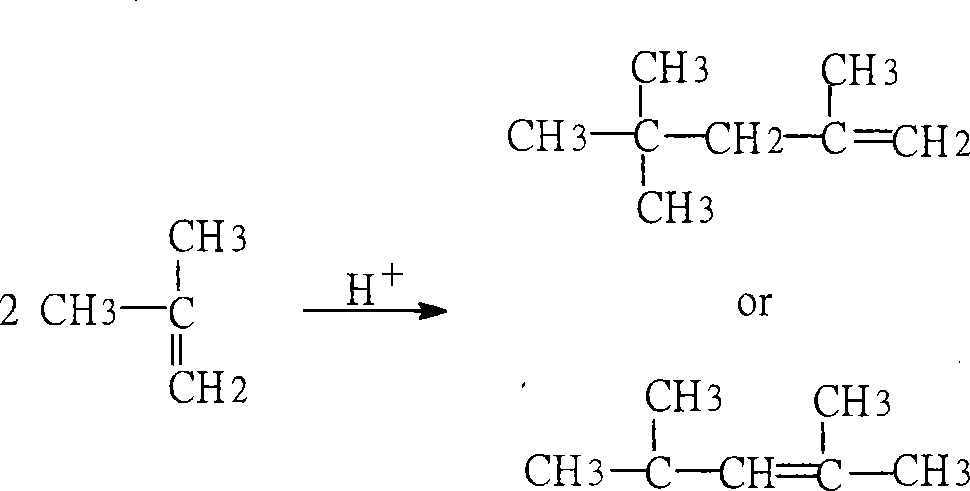

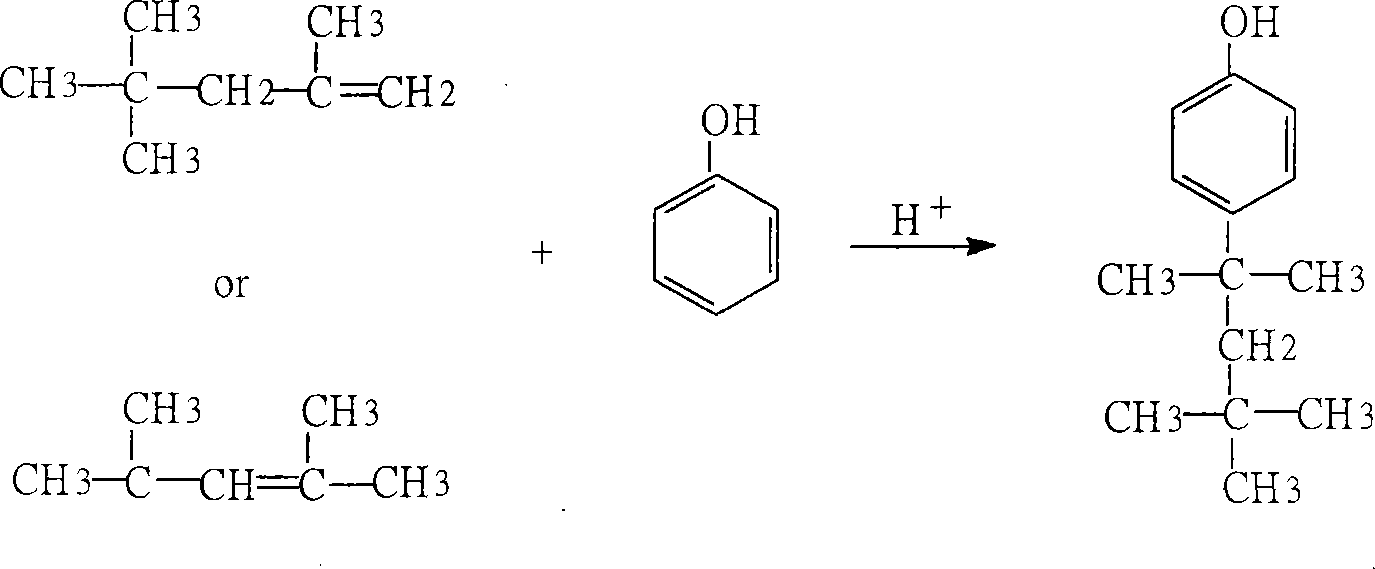

[0030] Adopt the preparation method of rubber tackifier p-tetraoctylphenol formaldehyde resin of the present invention, wherein the preparation of p-tetraoctylphenol is the sulfuric acid esterification, heating and degassing containing about 80% C 4 The addition mixture (by-product) is used as the raw material; the isobutylene dimer with the content of the target fraction > 98% obtained by distillation and cutting at 75°C-105°C is used as an alkylating agent; Na-type sulfonated styrene-ethylene di Alkene copolymer strongly basic anion exchange resin, which is converted into H-type sulfonated styrene-ethylene-diene copolymer strong acid cation exchange resin by acidification as an alkylation catalyst, and undergoes an alkylation reaction with phenol at 100°C. The alkylation mixed solution is distilled and cut at 220°C-270°C to obtain p-tertoctylphenol; then p-tertoctylphenol a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com