A kind of antibacterial type high hardness shoe material and preparation method thereof

A high-hardness, shoe material technology, applied in footwear, applications, apparel, etc., can solve problems such as poor flexibility, poor softness, and poor elasticity, and achieve the effect of improving bacteria resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

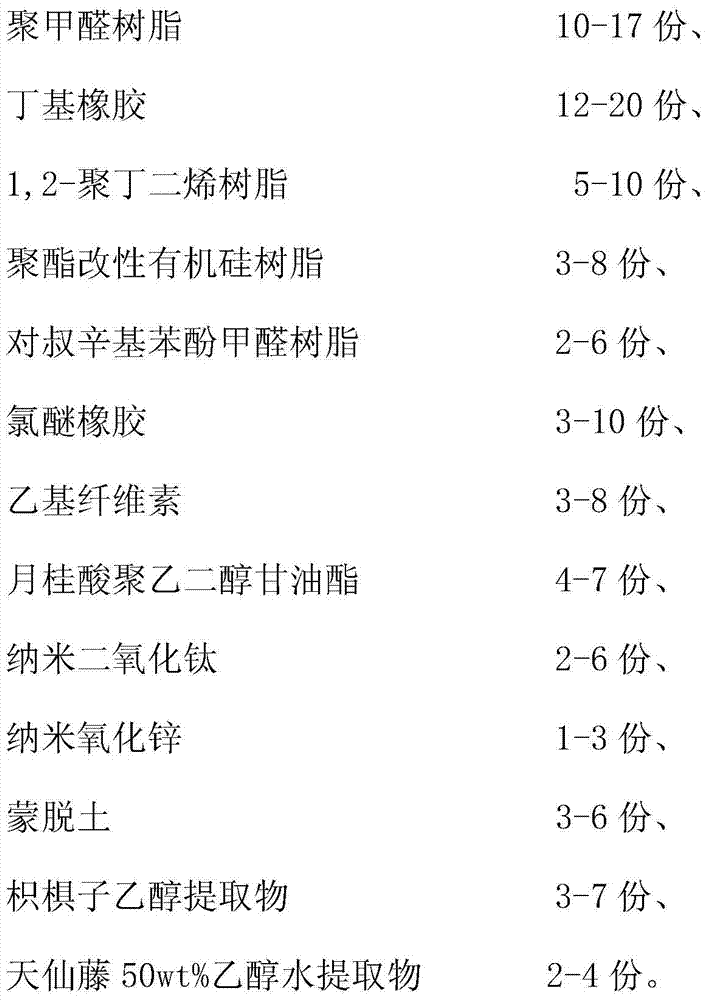

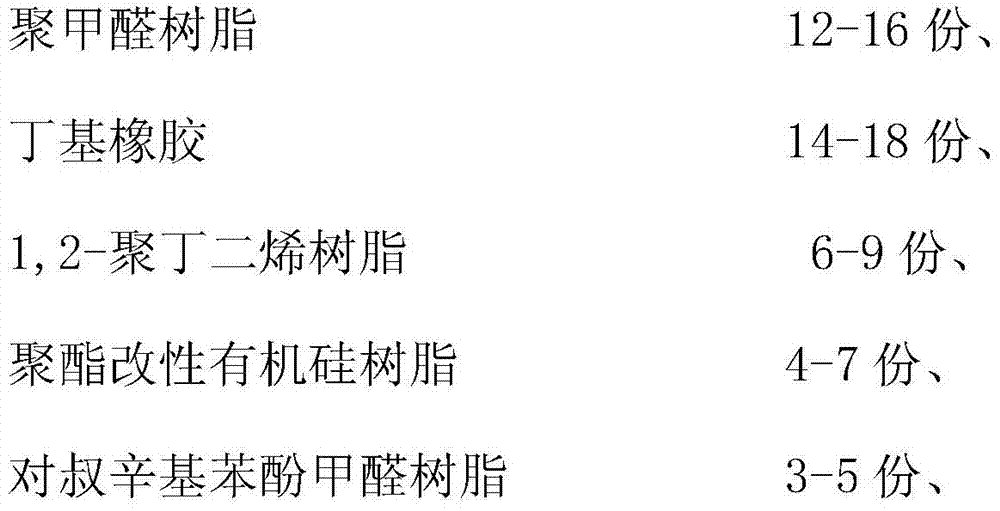

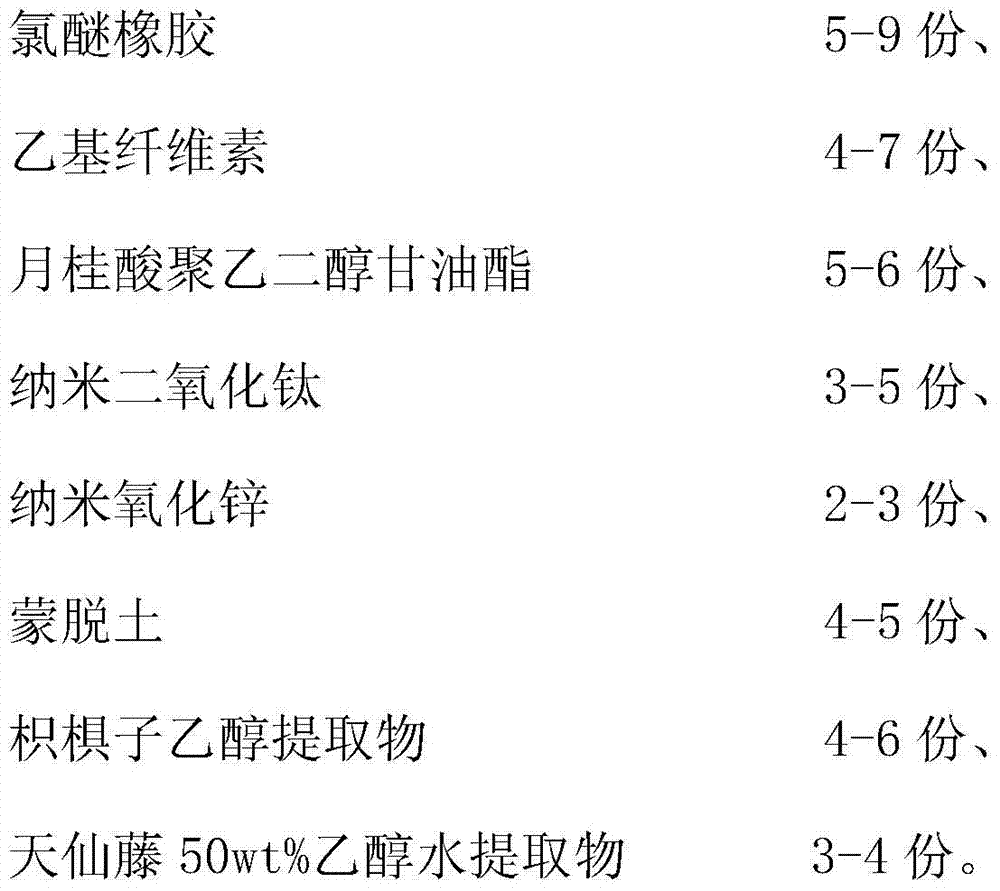

Method used

Image

Examples

Embodiment 1

[0021] (1) Hovenia dulcis and Tianxianteng were vacuum dried. After vacuum drying, they were separately extracted with ethanol and 50wt% ethanol aqueous solution. The extraction temperature was 60℃, the extraction time was 2h, and the weight ratio of material to liquid was 1:8. After leaching and filtering, the filtrate was concentrated in vacuum respectively, and after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Tianxianteng were obtained;

[0022] (2) Set the temperature in the reactor to 85℃, add 17 parts of polyoxymethylene resin, 12 parts of butyl rubber, 5 parts of 1,2-polybutadiene resin, and 3 parts of polyester modified silicone resin by weight , 6 parts of tert-octylphenol formaldehyde resin, 10 parts of chloroether rubber, 3 parts of ethyl cellulose, 7 parts of lauric acid polyethylene glycol glyceride, mechanically stir the materials in the reactor, the stirring speed is 90rpm, Stir evenly;

[0023] (3) Raise the temperat...

Embodiment 2

[0025] (1) Hovenia dulcis and Tianxianteng were vacuum dried. After vacuum drying, they were separately extracted with ethanol and 50wt% ethanol aqueous solution. The extraction temperature was 50℃, the extraction time was 5h, and the weight ratio of material to liquid was 1:4. After leaching and filtering, the filtrate was concentrated in vacuum respectively, and after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Tianxianteng were obtained;

[0026] (2) Set the temperature in the reactor to 65℃, add 10 parts of polyoxymethylene resin, 20 parts of butyl rubber, 10 parts of 1,2-polybutadiene resin, and 8 parts of polyester modified silicone resin by weight. , 2 parts of tert-octyl phenol formaldehyde resin, 3 parts of chloroether rubber, 8 parts of ethyl cellulose, 4 parts of lauric acid polyethylene glycol glyceride, mechanically stir the materials in the reactor, the stirring speed is 50 rpm, Stir evenly;

[0027] (3) Raise the tempe...

Embodiment 3

[0029] (1) Hovenia dulcis and Tianxianteng were vacuum dried. After vacuum drying, they were separately extracted with ethanol and 50wt% ethanol aqueous solution. The extraction temperature was 60℃, the extraction time was 2h, and the weight ratio of material to liquid was 1:8. After leaching and filtering, the filtrate was concentrated in vacuum respectively, and after concentration, the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Tianxianteng were obtained;

[0030] (2) Set the temperature in the reactor to 85°C, add 12 parts of polyoxymethylene resin, 18 parts of butyl rubber, 6 parts of 1,2-polybutadiene resin, and 7 parts of polyester modified silicone resin by weight , 3 parts of tert-octylphenol formaldehyde resin, 5 parts of chloroether rubber, 4 parts of ethyl cellulose, 6 parts of lauric acid polyethylene glycol glyceride, mechanically stir the materials in the reactor, the stirring speed is 90rpm, Stir evenly;

[0031] (3) Raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com