Degradable foamed plastic and preparation method thereof

A foamed plastic and foam stabilizer technology, applied in the field of composite materials, can solve the problems of long degradation cycle and incomplete decomposition of components, and achieve the effects of short degradation cycle, simple and easy preparation process, and high degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

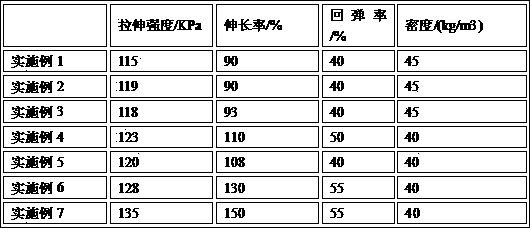

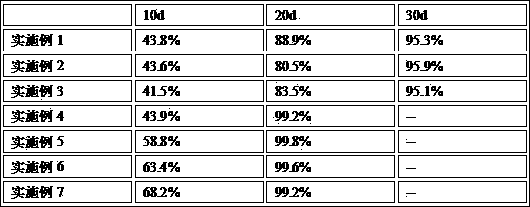

Examples

Embodiment 1

[0016] A degradable foamed plastic, the components and the mass fraction of each component are as follows: 60-80 parts of polylactic acid, 20-30 parts of starch, 1.2-3.6 parts of lysine diisocyanate, 5-15 parts of polycaprolactone, 1~6 parts of trimethylolpropane, 1~3 parts of tetrabutyl titanate, 1~5 parts of polyvinyl ester, 1~3 parts of maleic anhydride, 3~8 parts of glycerol, plasticizer triglyceride 2~5 parts, antioxidant 1010 1~3 parts, foam stabilizer L-580 2~5 parts.

[0017] Mix polycaprolactone, polylactic acid and starch evenly, stir, then add maleic anhydride, lysine diisocyanate, trimethylolpropane, tetrabutyl titanate, polyvinyl ester and glycerin, stir for 30 minutes , add the remaining components, put it in the oven for aging, and take it out after 20 minutes to get the finished product.

Embodiment 2

[0019] A degradable foamed plastic, the components and the mass fraction of each component are as follows: 60-80 parts of polylactic acid, 20-30 parts of starch, 1.2-3.6 parts of lysine diisocyanate, 5-15 parts of polycaprolactone, 1~6 parts of trimethylolpropane, 1~3 parts of tetrabutyl titanate, 1~5 parts of polyvinyl ester, 1~3 parts of maleic anhydride, 3~8 parts of glycerol, plasticizer triglyceride 2~5 parts, antioxidant 1010 1~3 parts, foam stabilizer L-580 2~5 parts.

[0020] Mix polycaprolactone, polylactic acid and starch evenly, stir, then add maleic anhydride, lysine diisocyanate, trimethylolpropane, tetrabutyl titanate, polyvinyl ester and glycerin, stir for 30 minutes , add the remaining components, put it in the oven for aging, and take it out after 20 minutes to get the finished product.

Embodiment 3

[0022] A degradable foamed plastic, the components and the mass fraction of each component are as follows: 60-80 parts of polylactic acid, 20-30 parts of starch, 1.2-3.6 parts of lysine diisocyanate, 5-15 parts of polycaprolactone, 1~6 parts of trimethylolpropane, 1~3 parts of tetrabutyl titanate, 1~5 parts of polyvinyl ester, 1~3 parts of maleic anhydride, 3~8 parts of glycerol, plasticizer triglyceride 2~5 parts, antioxidant 1010 1~3 parts, foam stabilizer L-580 2~5 parts.

[0023] Mix polycaprolactone, polylactic acid and starch evenly, stir, then add maleic anhydride, lysine diisocyanate, trimethylolpropane, tetrabutyl titanate, polyvinyl ester and glycerin, stir for 30 minutes , add the remaining components, put it in the oven for aging, and take it out after 20 minutes to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com