Polyvinyl alcohol film and preparation method thereof

A technology of polyvinyl alcohol film and polyvinyl alcohol, applied in sustainable manufacturing/processing, bio-packaging, sustainable packaging, etc., can solve problems such as poor compatibility and difficult molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

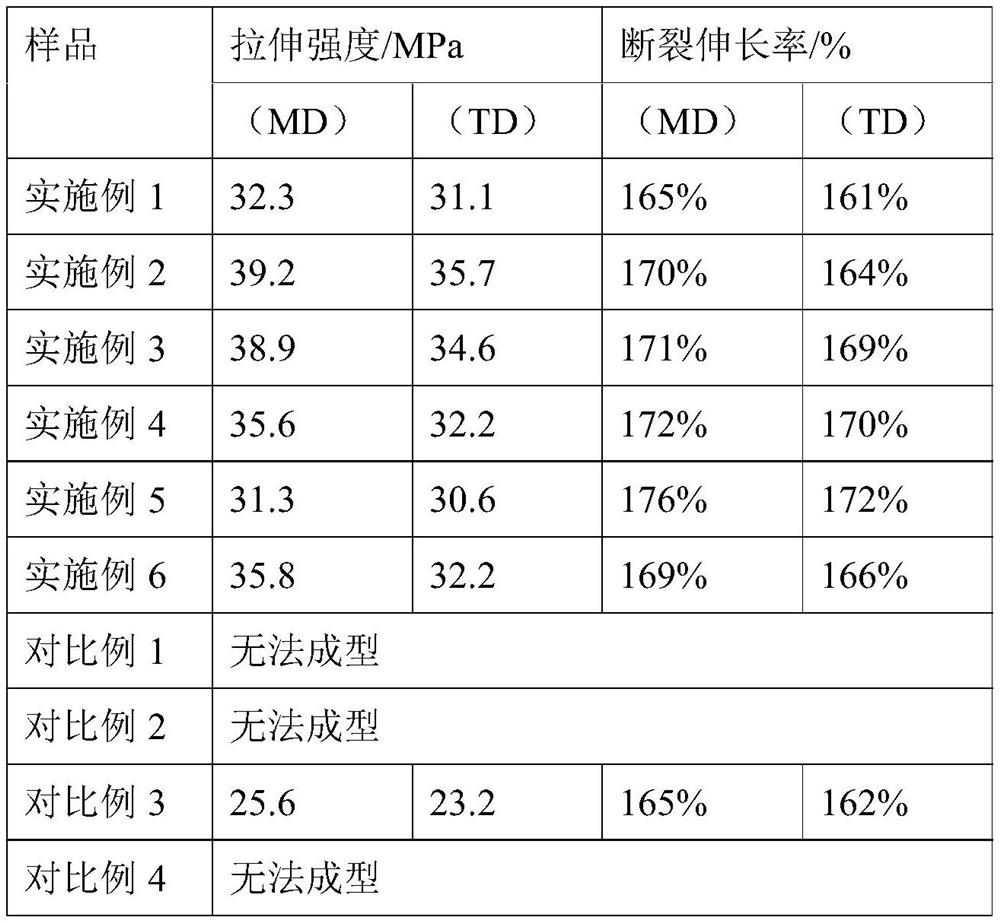

Examples

Embodiment 1

[0030] The polyvinyl alcohol film of this embodiment is made from the following raw materials by weight: 100 parts of polyvinyl alcohol, 60 parts of filler, 30 parts of reinforcing agent, 0.3 parts of bio-based compatibilizer, and 5 parts of plasticizer. The polyvinyl alcohol used in this example has a polymerization degree of 1500 and an alcoholysis degree of 85%; the filler used is starch, the bio-based compatibilizer is LDI, and the strengthening agent is calcium sulfate crystal with a weight ratio of 1:1 whisker and calcium carbonate; the plasticizer used is ethylene glycol and glycerol in a weight ratio of 1:1. The polyvinyl alcohol film of this example was prepared by the method of Example 7.

Embodiment 2

[0032] The polyvinyl alcohol film of this embodiment is made from the following raw materials by weight: 100 parts of polyvinyl alcohol, 120 parts of filler, 30 parts of reinforcing agent, 1 part of bio-based compatibilizer, and 10 parts of plasticizer. The polyvinyl alcohol used in this example has a degree of polymerization of 3500 and an alcoholysis degree of 99%; the filler used is starch, the bio-based compatibilizer is LDI, and the strengthening agent is calcium sulfate crystal with a weight ratio of 1:1 whisker and talc; the plasticizers used are glycerol and isosorbide in a weight ratio of 1:1. The polyvinyl alcohol film of this example was prepared by the method of Example 7.

Embodiment 3

[0034] The polyvinyl alcohol film of this embodiment is made from the following raw materials by weight: 100 parts of polyvinyl alcohol, 100 parts of filler, 20 parts of reinforcing agent, 0.7 part of bio-based compatibilizer, and 8 parts of plasticizer. The polyvinyl alcohol used in this example has a degree of polymerization of 2500 and an alcoholysis degree of 92%; the filler used is starch, the bio-based compatibilizer is LDI, and the reinforcing agent is calcium sulfate crystal with a weight ratio of 1:1 whisker and calcium carbonate; the plasticizers used are isosorbide and sorbitol in a weight ratio of 1:1. The polyvinyl alcohol film of this example was prepared by the method of Example 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com