Phosphorus-nitrogen flame retardant and preparation method thereof

A phosphorus-nitrogen flame retardant and solvent technology, applied in the field of phosphorus-nitrogen flame retardant and its preparation, can solve the problems of threatening human life and property safety, releasing a large amount of smoke, dust and poisonous gas, application restrictions and prohibitions, etc., and achieves easy operation. , The effect of less toxic gas and less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

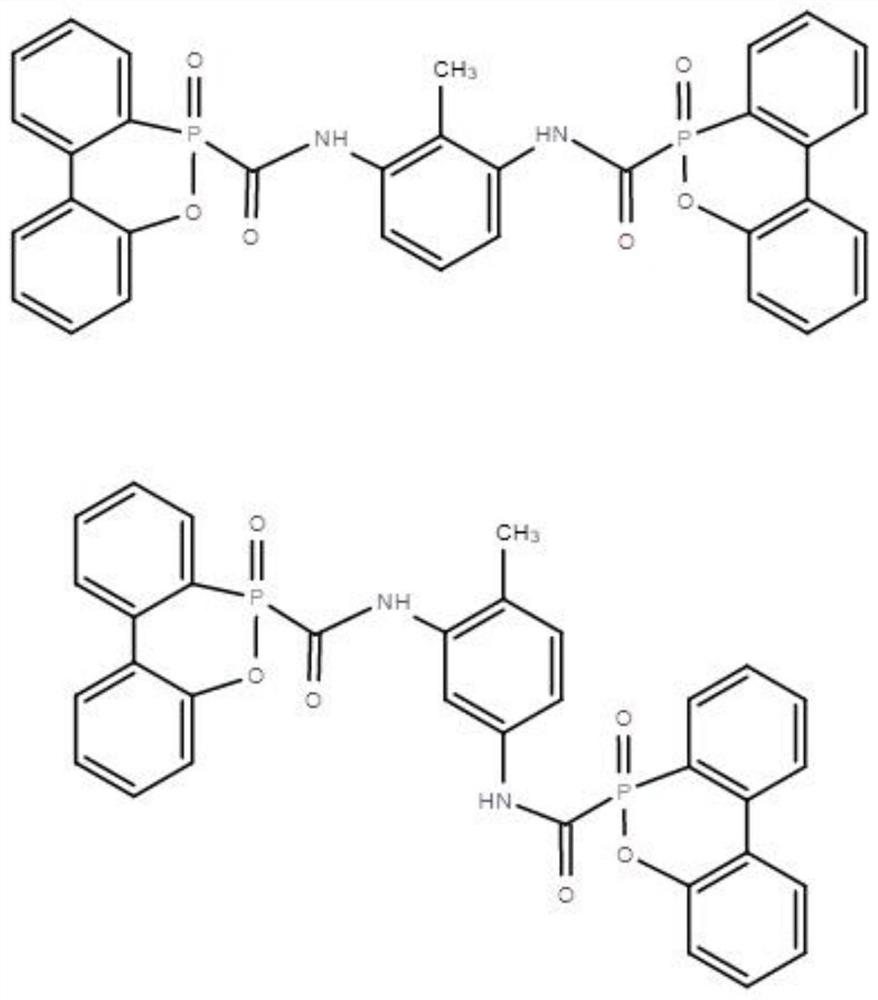

[0026] Add 216g of phosphorus-containing compound DOPO, 174g of toluene diisocyanate (TDI), and 1g of 2-methylimidazole into 1000g of solvent methylene chloride, set the temperature at 60°C, and react for 10 hours under stirring.

[0027] The resulting product liquid was rotary evaporated to remove the solvent, and the remaining solid product was dried at 50°C for 2 hours to obtain a phosphorus-nitrogen flame retardant with a yield of about 97.3%. Its structural formula is as follows: figure 1 shown.

Embodiment 2

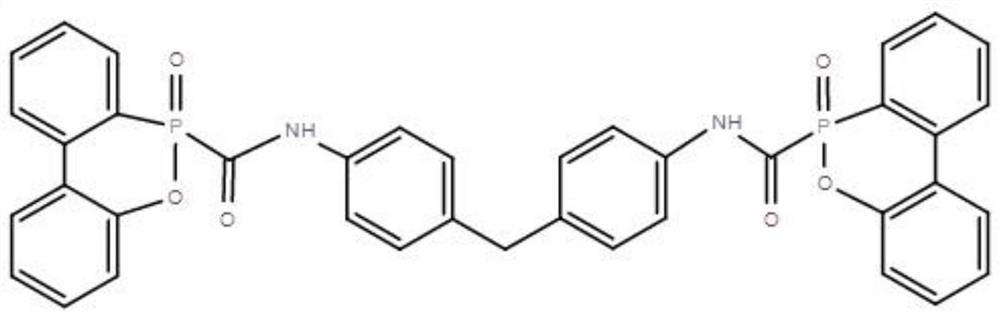

[0029] Add 432g of phosphorus-containing compound DOPO, 250g of diphenylmethane diisocyanate (MDI), and 1.2g of 2-ethyl-4-methyl into 1200g of solvent cyclohexanone, set the temperature at 65°C, and react for 12 hours under stirring .

[0030] The resulting product liquid was rotary evaporated to remove the solvent, and the remaining solid product was dried at 50°C for 2 hours to obtain a phosphorus-nitrogen flame retardant with a yield of about 96.8%. Its structural formula is as follows: figure 2 shown.

Embodiment 3

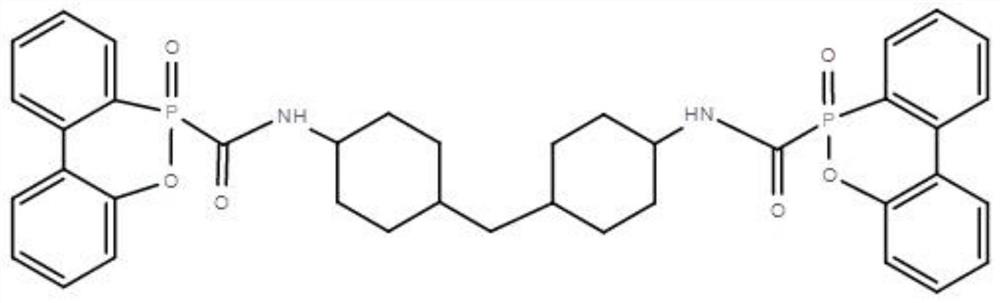

[0032] Add 216g of phosphorus-containing compound DOPO, 262.4g of dicyclohexylmethane diisocyanate (HMDI), 1.6g of 2-undecylimidazole into 1500g of solvent acetone, set the temperature at 55°C, and react for 14h under stirring.

[0033] The resulting product liquid was rotary evaporated to remove the solvent, and the remaining solid product was dried at 50°C for 2 hours to obtain a phosphorus-nitrogen flame retardant with a yield of about 98.1%. Its structural formula is as follows: image 3 shown.

[0034] from Figure 4 It can be seen that: compared with the raw material phosphorus-containing compound DOPO, the 2384cm-1P-H characteristic peak of the phosphorus-containing compound DOPO completely disappears, and the 1660cm-1 amide C=O characteristic peak and 1511cm-1 amide N-H characteristic peak are obvious, indicating that the reaction synthesis is implemented Example 2 product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com