Preparation method of LDI-PCLLA-PEG-PCLLA/hydroxyapatite electrospun fiber membrane as well as product and application thereof

A technology of hydroxyapatite and electrospun fibers, applied in medical science, prosthesis, tissue regeneration, etc., to achieve good biocompatibility, good mechanical properties, and good adhesion and crawling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

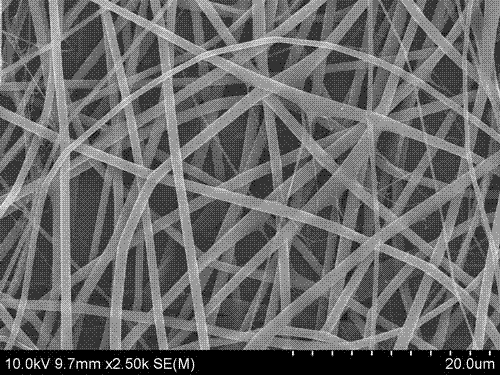

[0041] Heat the PCLLA-PEG-PCLLA raw material to 50 degrees Celsius and vacuumize it. After filling the flask with inert and dry argon, add LDI to react and use magnetic stirring to keep the reaction temperature at 60 degrees Celsius overnight for about 48 hours. Mix 0.2 g of the obtained cross-linked substance IPDI-PEG-PCLLA with 2 g of hexafluoroisopropanol at a mass ratio of 0.1:1, sonicate for 30 minutes, and magnetically stir overnight to obtain a uniform solution. After stirring at room temperature for 6~12h, a homogeneous solution was obtained. The obtained solution was put into a 10 mL glass syringe, and the composite was obtained by electrospinning equipment under the condition of spinning voltage of 10-13 KV, spinning receiving distance of 10-15 cm, and solution flow rate of 0.32-0.4 mL / h. Nanofiber membrane support, after spinning, put the obtained membrane into a vacuum oven to dry overnight at room temperature for future use.

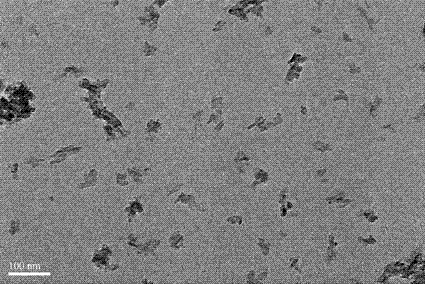

[0042] Among them, the SEM photos of...

Embodiment 2

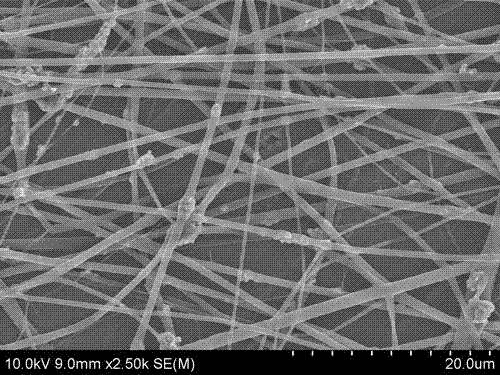

[0046] Heat the PCLLA-PEG-PCLLA raw material to 50 degrees Celsius and vacuumize it. After filling the flask with inert and dry argon, add LDI to react and use magnetic stirring to keep the reaction temperature at 60 degrees Celsius overnight for about 48 hours. Mix 0.2 g of the obtained cross-linked substance LDI-PEG-PCLLA with 2 g of hexafluoroisopropanol at a mass ratio of 0.1:1, sonicate for 30 minutes, and add an additional 5% (LDI-PEG-PCLLA: Hap mass ratio) Hap 0.11 g, continue to sonicate for 30 minutes, and obtain a homogeneous solution after magnetic stirring overnight. After stirring at room temperature for 6~12h, a homogeneous solution was obtained. The obtained solution was put into a 20mL glass syringe, and composite nanofibers were obtained by electrospinning equipment under the conditions of spinning voltage 10-15 KV, tray receiving distance 12-15 cm, and push flow rate 0.32-0.40mL / h Membrane support, after the completion, put the obtained membrane into a vacuu...

Embodiment 3

[0048] Heat the PCLLA-PEG-PCLLA raw material to 50 degrees Celsius and vacuumize it. After filling the flask with inert and dry argon, add LDI to react and use magnetic stirring to keep the reaction temperature at 60 degrees Celsius overnight for about 48 hours. Mix 0.2 g of the obtained cross-linked substance LDI-PEG-PCLLA with 2 g of hexafluoroisopropanol at a mass ratio of 0.1:1, sonicate for 30 minutes, and add an additional 10% (LDI-PEG-PCLLA:Hap mass ratio) Hap 0.22g, continue to sonicate for 30 minutes, and obtain a homogeneous solution after magnetic stirring overnight. After stirring at room temperature for 6~12h, a homogeneous solution was obtained. The resulting solution was put into a 20mL glass syringe, and the composite nanofibers were obtained by electrospinning equipment under the conditions of spinning voltage 10-15 KV, tray receiving distance 12-15 cm, and push flow rate 0.32-0.40mL / h Membrane support, after the completion, put the obtained membrane into a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com