Acrylic carboxyl polyurethane powder coating for ceramics and preparation method thereof

A technology of acrylic carboxyl group and polyurethane powder, which is applied in the field of coatings, which can solve the problems of poor durability, non-hard coatings, and poor flexibility, and achieve the effects of improved flexibility and chemical properties, good durability, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

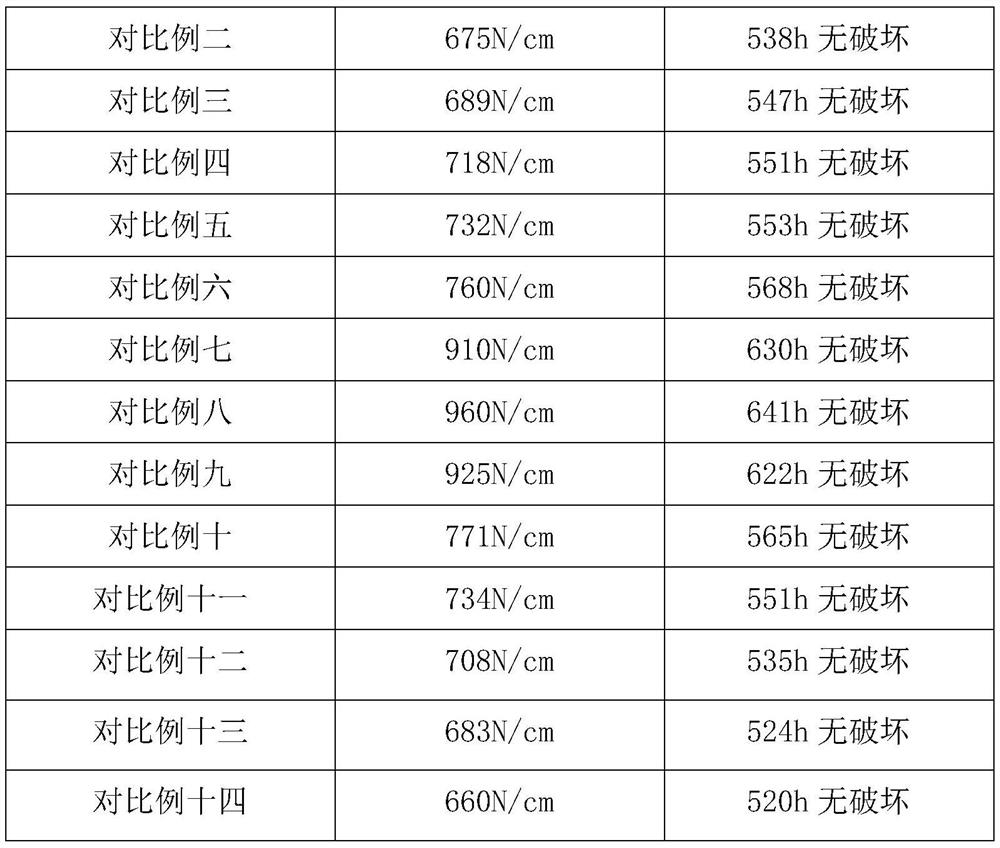

Examples

Embodiment 1

[0019] A kind of acrylic acid carboxyl polyurethane powder coating for ceramics proposed by the present invention comprises the following raw materials in parts by weight: 15 parts of propylene oxide, 18 parts of glycerin, 0.6 parts of yttrium oxide, 20 parts of lysine diisocyanate, 1 part of additive, propanediol 2 parts of amine, 8 parts of terpineol, 20 parts of acrylic acid, 3 parts of polydimethylsiloxane, 1 part of L-alanine-N-carboxy-cyclic anhydride;

[0020] Among them, the additive is obtained by compounding triethanolamine, N,N'-lutidine, sucrose fatty acid ester and α-furan formaldehyde in a mass ratio of 1:1:0.2:2.

[0021] Its preparation method comprises the following steps:

[0022] S1. Add the propylene oxide and glycerol of the specific gravity into the reaction kettle together, raise the temperature to 80°C, add yttrium oxide while keeping it warm, control the reaction pressure to 0.3MPa, stir and react for 1 hour, then add lysine diisocyanate and additives,...

Embodiment 2

[0027] A kind of acrylic carboxyl polyurethane powder coating for ceramics proposed by the present invention comprises the following raw materials in parts by weight: 20 parts of propylene oxide, 20 parts of glycerin, 0.9 parts of yttrium oxide, 25 parts of lysine diisocyanate, 1.5 parts of additives, propylene glycol 3 parts of amine, 10 parts of terpineol, 25 parts of acrylic acid, 5.25 parts of polydimethylsiloxane, 1.5 parts of L-alanine-N-carboxy-cyclic anhydride;

[0028] Among them, the additive is obtained by compounding triethanolamine, N,N'-lutidine, sucrose fatty acid ester and α-furan formaldehyde with a mass ratio of 2:1:0.5:3.5.

[0029] Its preparation method comprises the following steps:

[0030] S1. Add the propylene oxide and glycerin of the specific gravity into the reaction kettle, raise the temperature to 85°C, add yttrium oxide while keeping warm, control the reaction pressure to 0.4MPa, stir and react for 1.5h, then add lysine diisocyanate and additives...

Embodiment 3

[0035] A kind of acrylic carboxyl polyurethane powder coating for ceramics proposed by the present invention comprises the following raw materials in parts by weight: 25 parts of propylene oxide, 22 parts of glycerin, 1.2 parts of yttrium oxide, 30 parts of lysine diisocyanate, 2 parts of additives, propylene glycol 4 parts of amine, 12 parts of terpineol, 30 parts of acrylic acid, 8 parts of polydimethylsiloxane, 2 parts of L-alanine-N-carboxy-cyclic anhydride;

[0036] Among them, the additive is obtained by compounding triethanolamine, N,N'-lutidine, sucrose fatty acid ester and α-furan formaldehyde with a mass ratio of 3:1:0.7:5.

[0037] Its preparation method comprises the following steps:

[0038] S1. Add the propylene oxide and glycerin of the specific gravity into the reaction kettle, raise the temperature to 90°C, add yttrium oxide while keeping it warm, control the reaction pressure to 0.5MPa, stir and react for 2 hours, then add lysine diisocyanate and additives, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com