Electric wire and cable soft polychloroethylene plastics for vehicle and preparation method thereof

A soft polyvinyl chloride, wire and cable technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as troubles, and achieve the effects of simple processing technology, fast extrusion speed, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

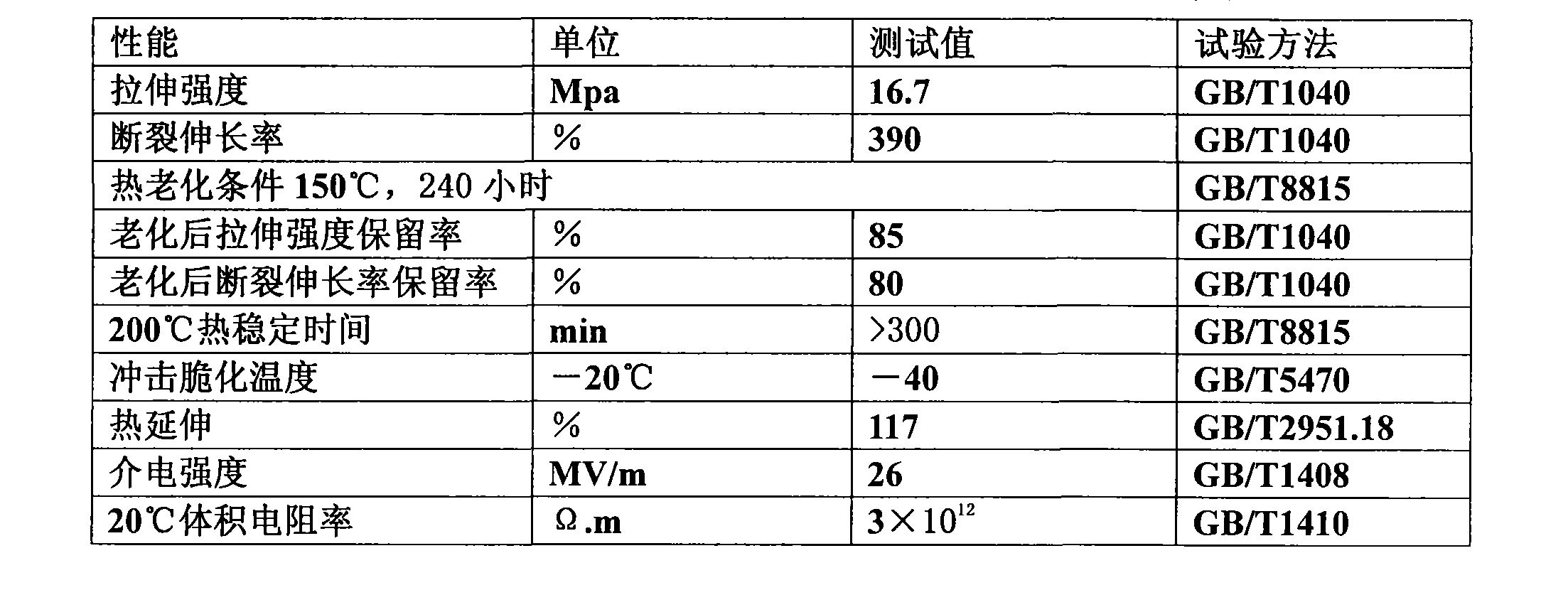

Image

Examples

Embodiment 1

[0041] PVC (polymerization degree 1300) 100 parts

[0042] TOTM 30 copies

[0043] DOS 15 copies

[0044] Calcium zinc stabilizer (9700 brand produced by German Xiongpai company) 6 parts

[0045] 0.3 parts of stearic acid

[0046] Polyethylene wax 0.1 parts

[0047] Antioxidant B225 (Ciba Company) 0.6 parts

[0048] Antioxidant DLTDP 0.4 parts

[0049] clay 10 parts

[0050] Polyurethane 6 parts

[0051] Initiator (dicumyl peroxide) 0.1 part

[0052] 3 parts of cross-linking auxiliary agent (TAIC)

Embodiment 2

[0055] PVC (polymerization degree 1300) 100 parts

[0056] TOTM 20 copies

[0057] DOS 35 copies

[0058] Calcium zinc stabilizer (9700 brand) 10 parts

[0059] Stearic acid 0.1 parts

[0060] Polyethylene wax 0.5 parts

[0061] Antioxidant B225 0.8 parts

[0062] Antioxidant DLTDP 0.2 parts

[0063] clay 20 parts

[0064] Polyurethane 10 parts

[0065] Initiator (dicumyl peroxide) 0.2 parts

[0066] 3 parts of cross-linking auxiliary agent (TAIC)

Embodiment 3

[0069] PVC (polymerization degree 1300) 100 parts

[0070] TOTM 40 copies

[0071] DOS 15 copies

[0072] Calcium zinc stabilizer (9700 brand) 4 parts

[0073] 0.5 parts of stearic acid

[0074] Polyethylene wax 0.3 parts

[0075] Antioxidant B225 0.5 parts

[0076] Antioxidant DLTDP 0.2 parts

[0077] Clay 30 parts

[0078] Polyurethane 10 parts

[0079] Initiator (dicumyl peroxide) 0.05 part

[0080] 2 parts of cross-linking auxiliary agent (TAIC)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com