Centrifugal type composite coal-grinding and powder-spraying machine

A compound mill and duster technology, which is applied in the direction of block/powder fuel preparation, block/powder supply/distribution, combustion methods, etc., can solve the problems of environmental pollution and waste, and achieve less environmental pollution and better combustion Complete, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

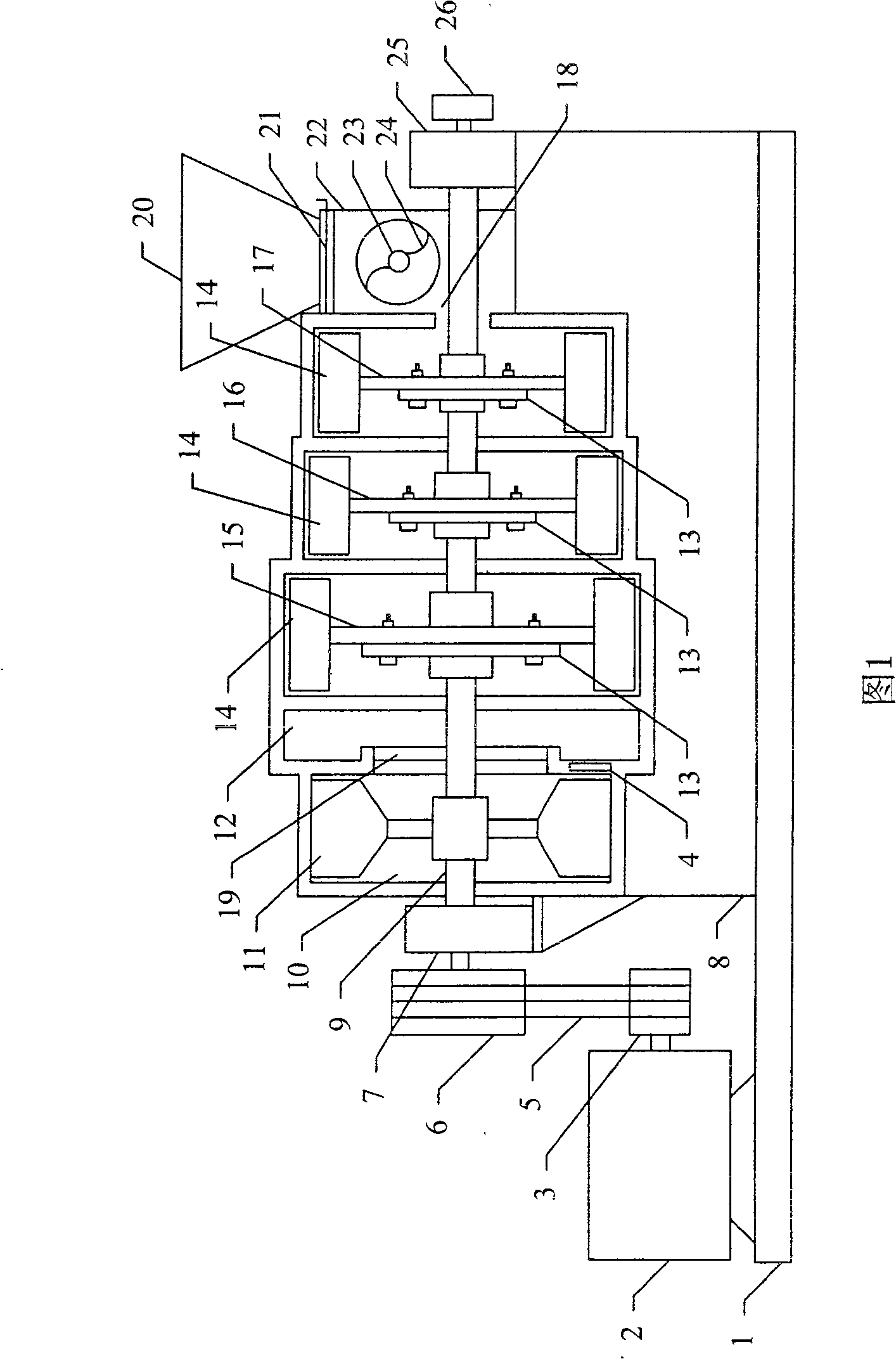

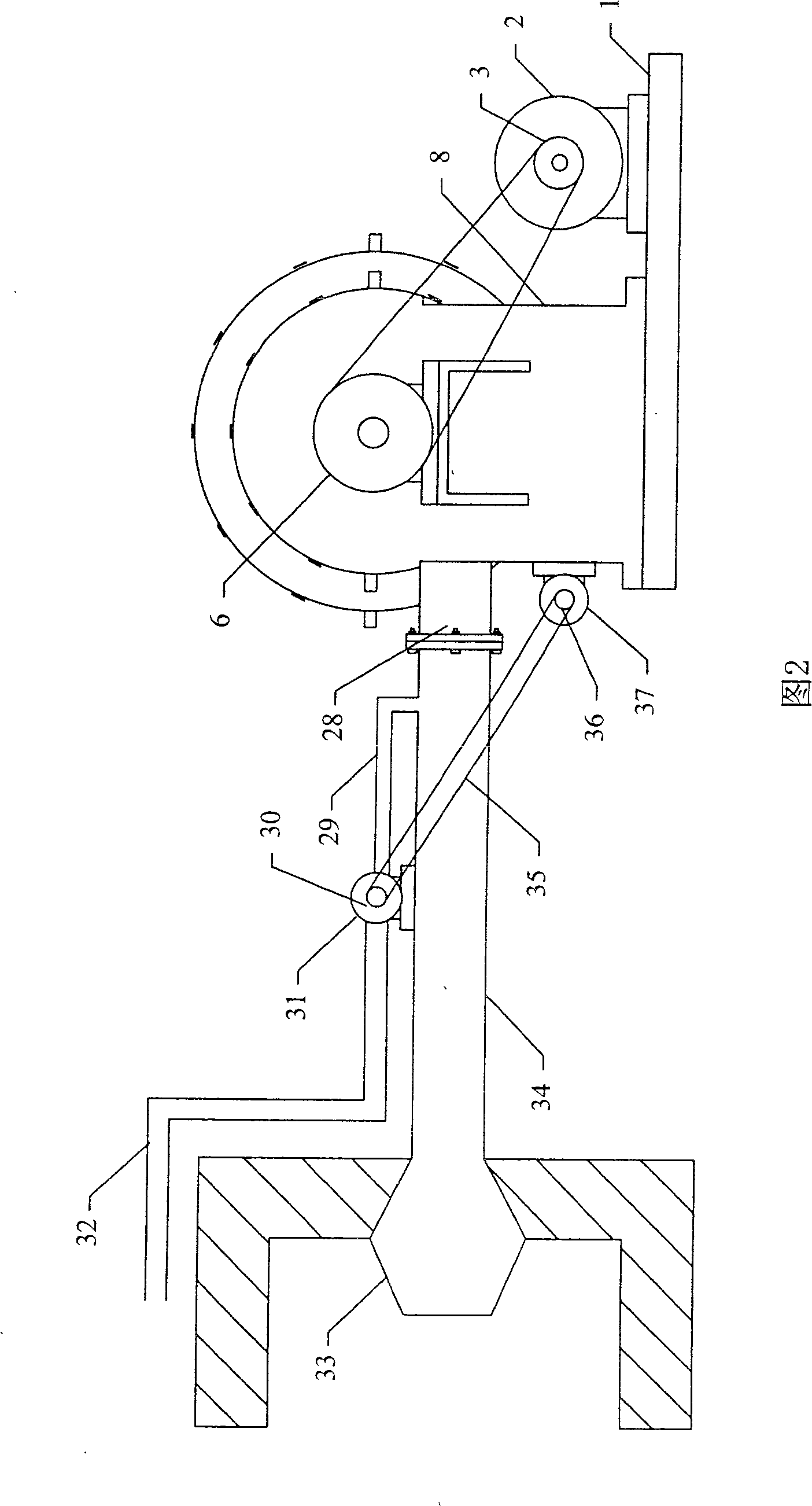

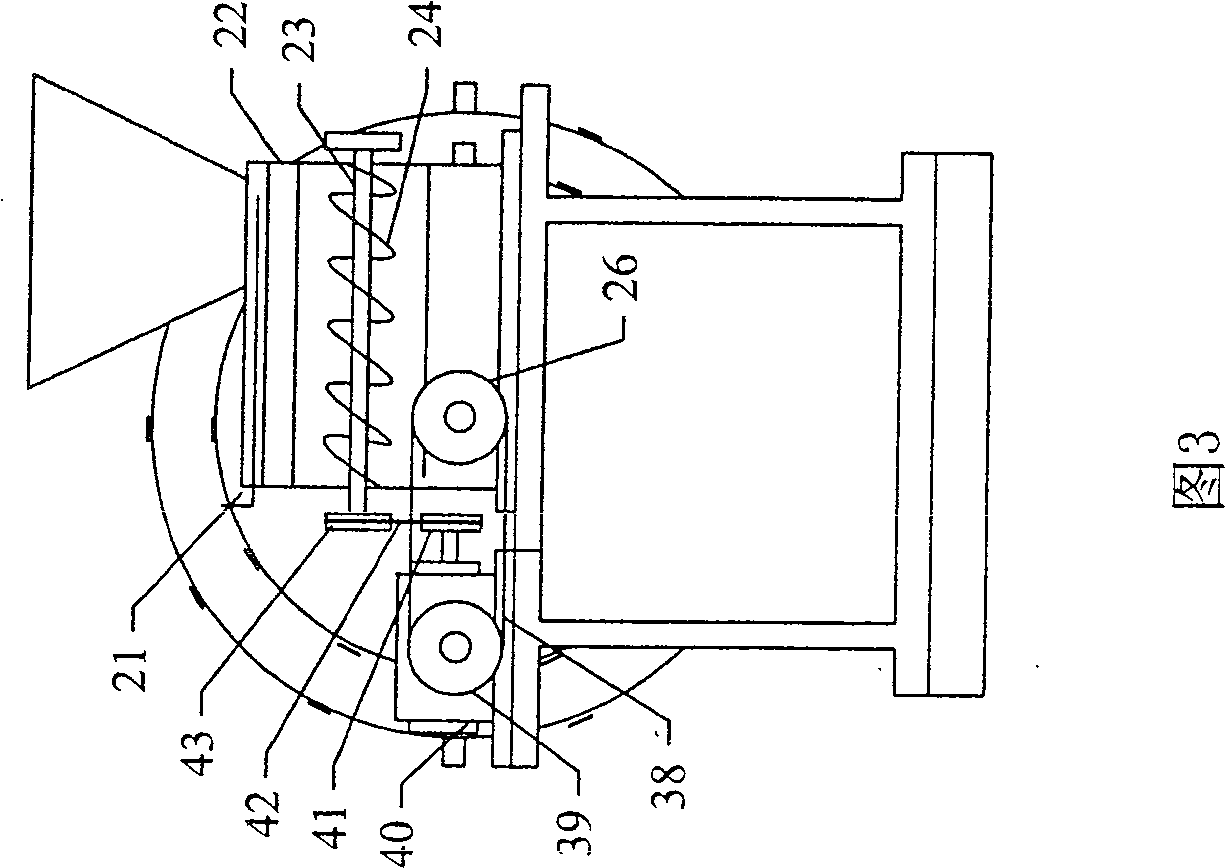

[0010] figure 1 , figure 2 The upper end of the seat frame 1 shown in the figure is equipped with a base 8, and the base is equipped with a main shaft 9, and the middle part of the main shaft is provided with a set of rough grinding flyweight bodies 17, two sets of fine grinding flyweight bodies 16, and three sets of fine grinding flyweight bodies 15 , The middle part of the flyweight body is provided with an impeller, the flyweight body and the impeller are connected as a whole, and the impeller is fastened on the flange 13 by bolts. The flange is fixed on the main shaft, the outer end of the fly hammer body is provided with a fly hammer head 14, the front end of the body is provided with an air inlet bin 12, the front side of the air inlet bin is provided with a spoiler 19, and the lower end of the spoiler is provided with a spoiler 19. There is a powder suction port 4, the front end of the spoiler is provided with a fan compartment 10, and the fan compartment is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com