Caloric synergistic environment-friendly reclamation method for waste integrated circuit boards

An integrated circuit and resource-based technology, which is applied in chemical instruments and methods, separation methods, gasification processes, etc., can solve the problems of lack of large-scale equipment, collaborative smelting equipment and flue gas treatment equipment with high requirements, and inability to carry out industrial production. , to achieve the effects of no pollution to flue gas, short-process recovery of valuable metals, and improved crushing and sorting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

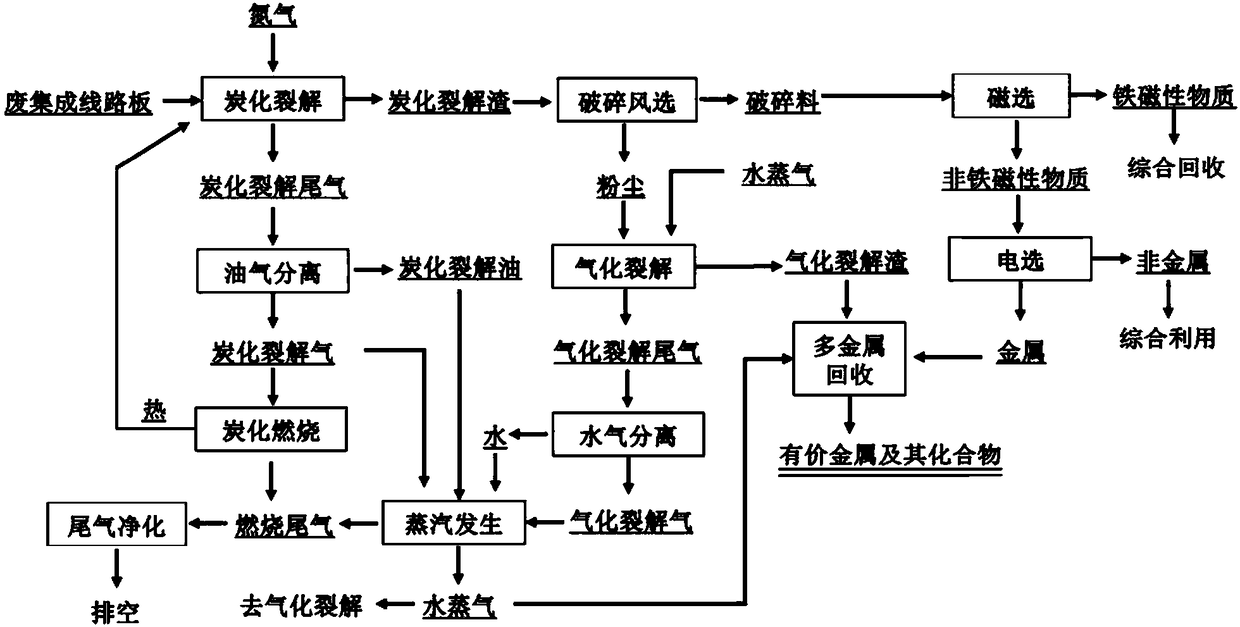

[0021] Follow the steps below to recycle:

[0022] (1) The waste integrated circuit board is carbonized and cracked to obtain carbonized cracking slag and carbonized cracking tail gas. During the carbonization and cracking process, the oxygen partial pressure is controlled to 6%, nitrogen protection is used, the carbonization cracking temperature is 400 ° C, and the carbonization cracking time is 1 hour. ;The carbonization and cracking tail gas is separated from oil and gas to obtain carbonization and cracking oil and carbonization and cracking gas, and the carbonization and cracking gas is obtained by carbonization and combustion to obtain combustion tail gas and heat, and the heat generated directly provides a heat source for carbonization and cracking;

[0023] (2) The carbonized cracking slag obtained by carbonization and cracking is crushed and winnowed to obtain crushed material and dust. During the crushed winnowing process, the crushed particle size is less than 100 mes...

Embodiment 2

[0028] Follow the steps below to recycle:

[0029] (1) The waste integrated circuit board is carbonized and cracked to obtain carbonized cracking slag and carbonized cracking tail gas. During the carbonization and cracking process, the oxygen partial pressure is controlled to 5%, nitrogen protection is used, the carbonization cracking temperature is 700 ° C, and the carbonization cracking time is 3 hours. ;The carbonization and cracking tail gas is separated from oil and gas to obtain carbonization and cracking oil and carbonization and cracking gas, and the carbonization and cracking gas is obtained by carbonization and combustion to obtain combustion tail gas and heat, and the heat generated directly provides a heat source for carbonization and cracking;

[0030] (2) The carbonized cracking slag obtained by carbonization and cracking is crushed and winnowed to obtain crushed material and dust. During the crushed winnowing process, the crushed particle size is less than 100 me...

Embodiment 3

[0035] Follow the steps below to recycle:

[0036](1) The waste integrated circuit board is carbonized and cracked to obtain carbonized cracking slag and carbonized cracking tail gas. During the carbonization and cracking process, the oxygen partial pressure is controlled to 3%, nitrogen protection is used, the carbonization cracking temperature is 450 ° C, and the carbonization cracking time is 2 hours. ;The carbonization and cracking tail gas is separated from oil and gas to obtain carbonization and cracking oil and carbonization and cracking gas, and the carbonization and cracking gas is obtained by carbonization and combustion to obtain combustion tail gas and heat, and the heat generated directly provides a heat source for carbonization and cracking;

[0037] (2) The carbonized cracking slag obtained by carbonization and cracking is crushed and winnowed to obtain crushed material and dust. During the crushed winnowing process, the crushed particle size is less than 100 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com