Mascara applicator

A mascara and application technology, which is applied in the field of application tools, can solve the problems of not being able to attach mascara to the root of the eyelashes, not being able to lift the eyelashes as a whole, not being able to adhere to the mascara and not being able to eyelashes, etc., to achieve a beautiful visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

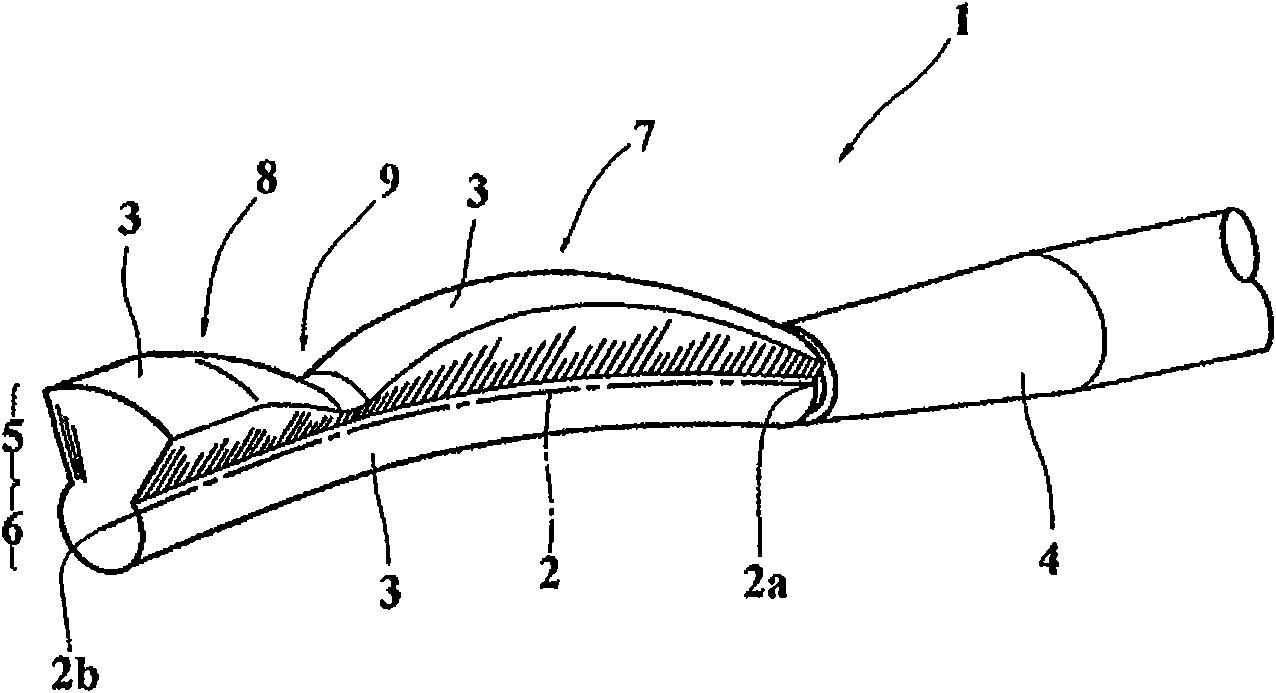

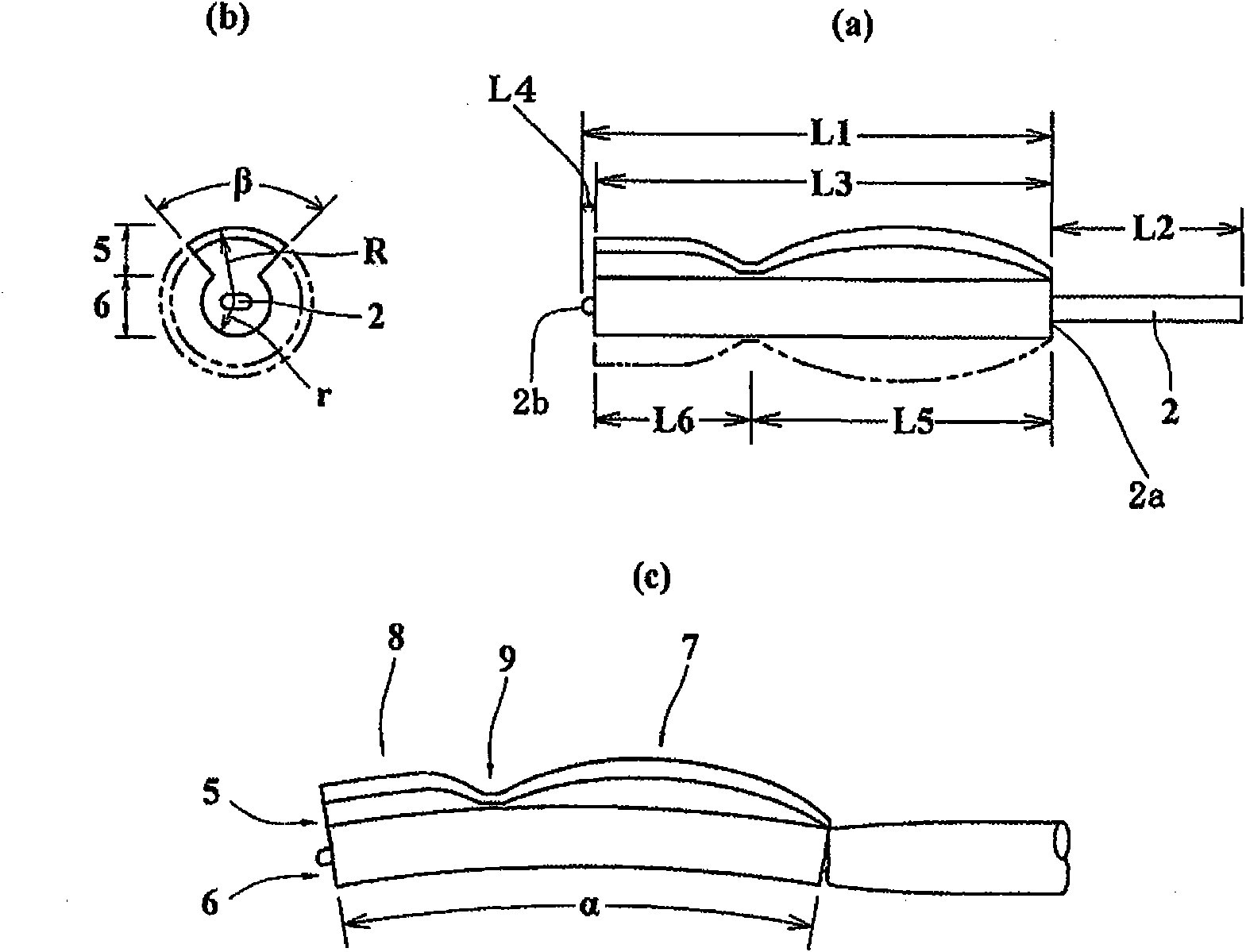

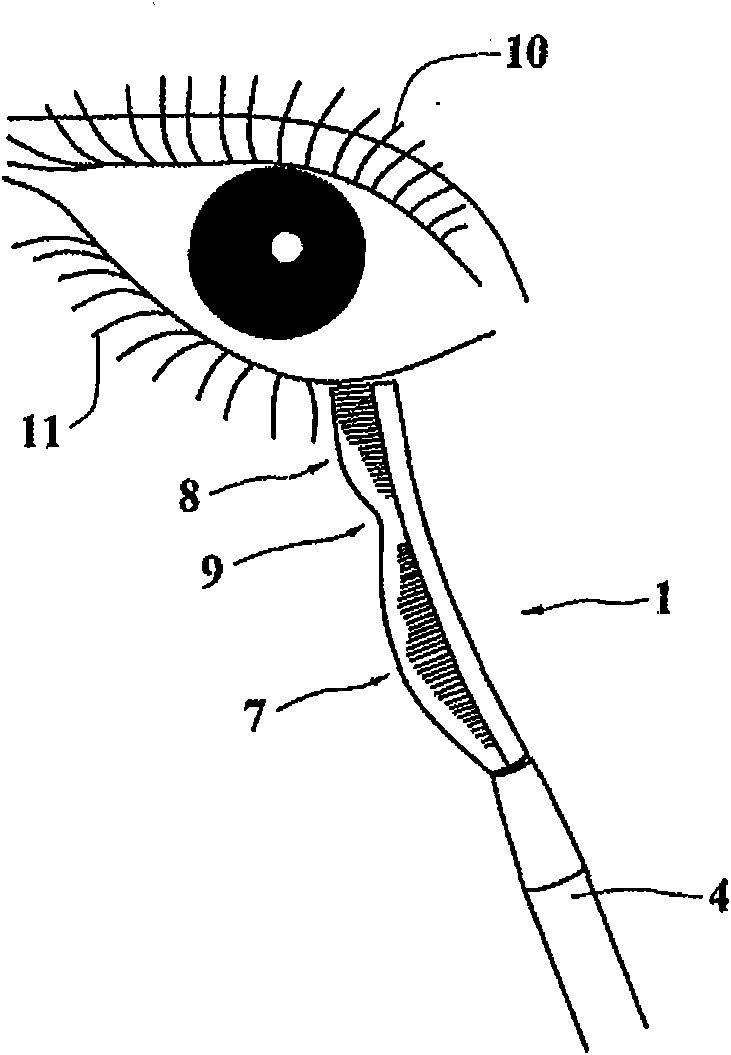

[0043] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. The mascara applicator (1) of this embodiment includes a metal core (2) and brush-like fibers (3) held by the core (2). The core (2) is held in a resin The front end of the cylindrical shaft rod (4).

[0044] The core material (2) is formed into a double helical shape by folding a linear metal wire in half, and twisting the two parallel metal wires with each other. The end portion is the base end portion side. In addition, it is preferable to set the outer diameter of the core material (2) to about 1.5 mm. Near the end portion of the base end portion (2a) side of the core material (2) is inserted into the front end of a cylindrical shaft rod (4) made of resin, so that the front end portion of the shaft rod (4) is used as the core material (2) The core material (2) is held in such a way that the base end portion (2a) of the core material (2) is held. ...

Embodiment 2

[0053] Another embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Such as Figure 4 As shown, the mascara applicator (101) of the present embodiment includes a core material (102) made of resin and an upper fin-like portion (103a) consisting of a plurality of fins extending from the core material (102) in the up-down direction. ) and the lower fin (103b).

[0054] The core material (102) is constituted as follows: using a conventionally known synthetic resin, such as polypropylene, it is formed into a shape having a curved portion (102b) bent into an arcuate shape, and the curved portion (102b) is the front end side, and the straight portion (102a) The proximal end side is attached to a handle (not shown) such as a shaft. At the front end of the curved portion (102b) of the core material (102), a front end portion (102c) protruding in a substantially half-oval shape is formed toward the front end in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com