Air cooling device and novel process for cooling high tower granulation fertilizer

An air-cooling, high-tower granulation technology, which is applied in the directions of dry gas arrangement, air conditioning system, space heating and ventilation, etc., can solve the problems of destroying the roundness of finished product particles, increasing the moisture content of products, and particle crushing, etc., to achieve guaranteed Particle appearance and smoothness, improvement of particle finish, and reduction of particle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

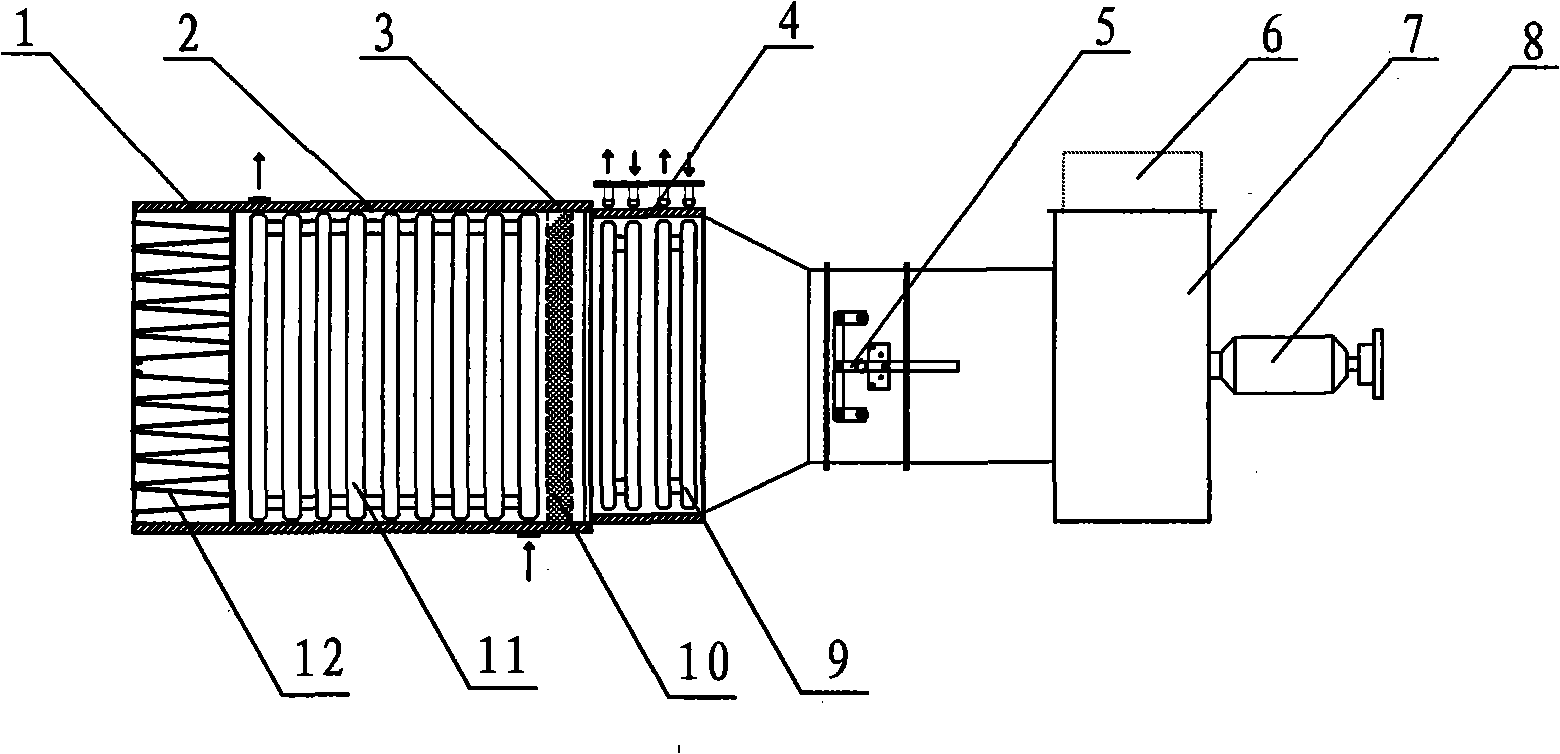

[0034] Embodiment 1 A kind of air cooling device, see image 3 , comprising an air filter 1, a heat exchanger 2, an air dehumidifier 3, an air preheater 4 and an induced draft fan 7, and in the air filter 3 casing, a cashmere felt filter medium 12 is evenly fixed; in the heat exchanger 2 A heat dissipation cooling pipe network 11 is arranged inside, the water inlet of which is grounded to the ground water source, and the extracted groundwater is used as the refrigerant. One end of the air inlet of the heat exchanger 2 is connected to the air filter 1, and one end of the air outlet is connected to the air dehumidifier 3 , the air dehumidifier 3 is provided with a water vapor condensation mesh 10 made of dense steel mesh for condensing moisture in the air, the air outlet of the air dehumidifier 3 is connected to the air preheater 4, and the air outlet of the air preheater 4 is connected To the induced draft fan 7, the cooled air is sent out from the air outlet 6, and the air pre...

Embodiment 2

[0041] Embodiment 2 A kind of air cooling device, see image 3 , is basically the same as Example 1, the difference is that: the filter medium 12 in the air filter 3 is a rock wool board; the water vapor condensation mesh 3 provided in the air dehumidifier 3 is made of asbestos; The sheet is spiral tubular.

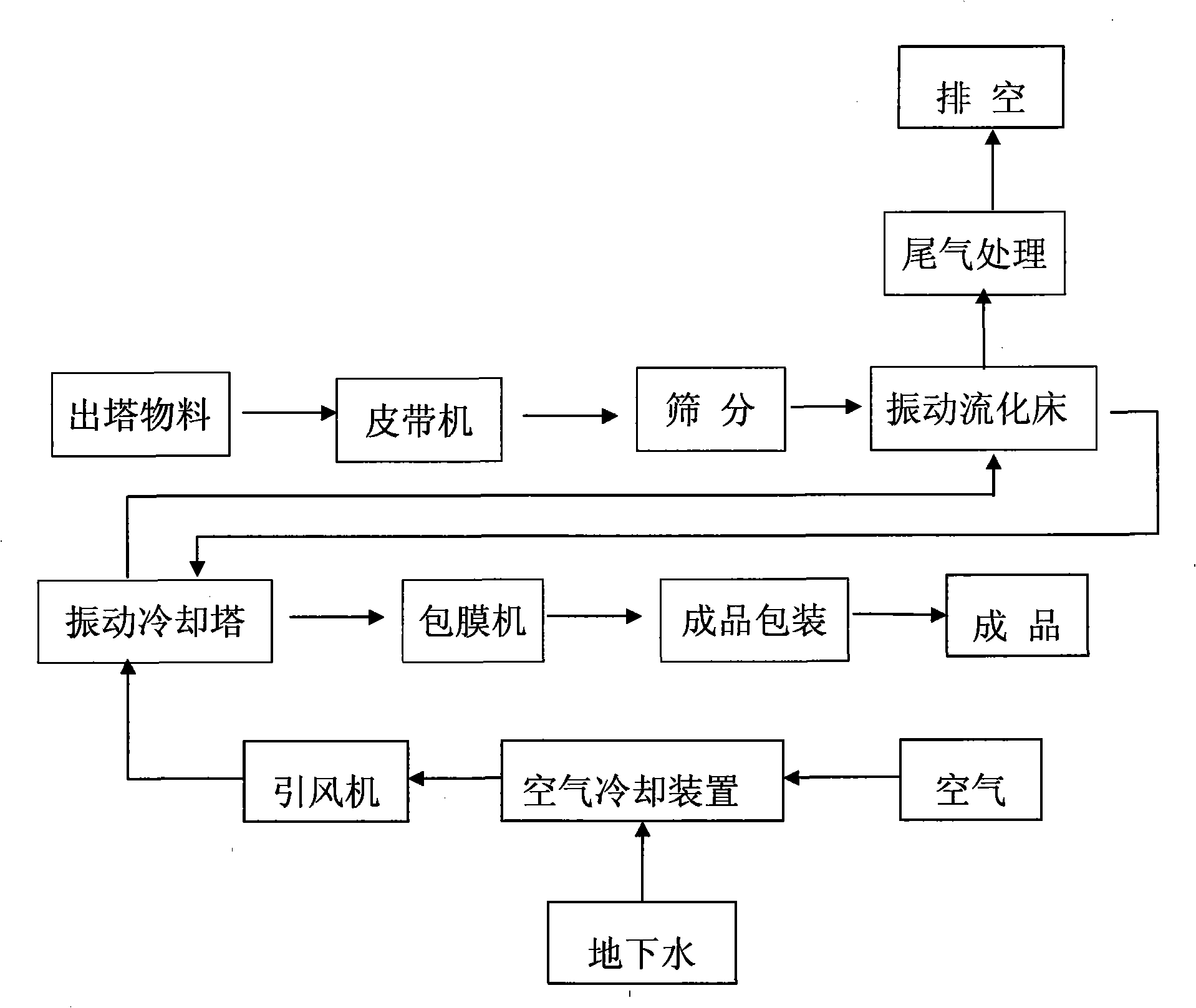

[0042] A new high-tower granulation fertilizer cooling process, the maximum working environment temperature is about 43 ℃, see figure 2 , its technological process is basically the same as embodiment 1, the difference is:

[0043] (1) The materials coming out of the tower at about 90°C are sent to the vibrating sieve for screening through the belt conveyor, and then sent to the vibrating fluidized bed. The hot materials are suspended and flowed in the fluidized bed for 22 minutes;

[0044] (2) In the air cooling device, the hot air is filtered and exchanged with groundwater at 20°C to obtain cold air at 24°C and a relative humidity of 40-45%. The mass ratio is 1.4:1; ...

Embodiment 3

[0046] Embodiment 3 A kind of air cooling device, see image 3 , is basically the same as Example 1, except that the filter medium 12 in the air filter 3 is a rock wool board.

[0047] A new cooling process for high-tower granulated fertilizer, see figure 2 , which is basically the same as in Example 1, except that:

[0048] In step (1), the materials coming out of the tower at about 95°C are sent to the vibrating screen for screening through the belt conveyor, and then sent to the vibrating fluidized bed for 35 minutes;

[0049] In step (2), the mass ratio of the amount of cold air passing into the vibration cooling tower and the amount of material entering the tower is 1.2: 1;

[0050] In step (3), the material from the fluidized bed is input into a vibrating cooling tower, and the material and the incoming cold air are exchanged for 35 minutes in the cooling tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com