Method for carrying out solid-liquid separation on high-temperature alpha gypsum slurry

A technology of solid-liquid separation and gypsum slurry, which is applied in the field of gypsum production and processing, can solve the problems of material scrapping, achieve low moisture content, and eliminate the effects of temperature and time conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

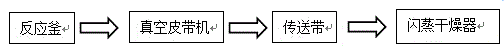

Image

Examples

Embodiment 1

[0034] A method for solid-liquid separation of α-gypsum high-temperature slurry, using the following steps:

[0035] (1) First crystallization. Grinding gypsum ore, desulfurized gypsum or phosphogypsum into dihydrate gypsum powder with a particle size distribution between 10-100 μm, and mixing dihydrate gypsum powder with water in a mixing tank to form a gypsum slurry with a concentration of 30-40%. And heated to 30 ℃ ~ 100 ℃, the mixed gypsum slurry enters the reaction kettle through the slurry pump, under the conditions of temperature 90 ℃ ~ 150 ℃, pressure 3.0 ~ 5.0MPa, and in the crystal transformation agent maleic anhydride Under the action of the first crystallization, about 98% of α-gypsum slurry is generated.

[0036](2) Secondary crystallization. On the basis of the first crystallization, the generated α-gypsum slurry enters another reactor, and under the conditions of temperature 110°C-150°C and pressure 3.0-4.0MPa, secondary crystallization is carried out under th...

Embodiment 2

[0044] A method for solid-liquid separation of α-gypsum high-temperature slurry, using the following steps:

[0045] (1) First crystallization. Referring to Example 1.

[0046] (2) Secondary crystallization. Referring to Example 1.

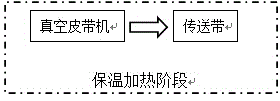

[0047] (3) High temperature dehydration, solid-liquid separation. Put the high-temperature α-gypsum slurry on the vacuum belt conveyor. At this time, the temperature of the slurry is 110°C-150°C, and the vacuum degree of the vacuum box under the vacuum dehydration belt is 0-1MPa;

[0048] The vacuum dehydration belt starts to dehydrate the high-temperature α-gypsum slurry. At this time, the material on the vacuum belt conveyor must be kept warm and heated. The method of installing an insulation cover on the vacuum belt conveyor and injecting high-temperature air is adopted. The heat transfer oil is used to directly heat the air. Let the air temperature reach 100 ℃ ~ 200 ℃, or directly pass in the hot flue gas with a temperature between 100 ℃ ~...

Embodiment 3

[0054] A method for solid-liquid separation of α-gypsum high-temperature slurry, using the following steps:

[0055] (1) First crystallization. Referring to Example 1.

[0056] (2) Secondary crystallization. Referring to Example 1.

[0057] (3) High temperature dehydration, solid-liquid separation. Put the high-temperature α-gypsum slurry on the vacuum belt conveyor. At this time, the temperature of the slurry is 110°C-150°C, and the vacuum degree of the vacuum box under the vacuum dehydration belt is 0.1MPa;

[0058] The vacuum dehydration belt starts to dehydrate the high-temperature α-gypsum slurry. At this time, the material on the vacuum belt conveyor must be kept warm and heated. The method of installing an insulation cover on the vacuum belt conveyor and injecting high-temperature steam is used to make the steam temperature reach 100 ℃ ~ 200 ℃; adopt pressure-holding measures while heat preservation and heating, the pressure-holding range is 1MPa; the material tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com