Cream-like silver brazing fluxes

A silver flux and paste technology, applied in the field of silver flux, can solve the problems of poor spreadability of silver solder, easy to agglomerate and harden, and poor activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, further illustrate the present invention in conjunction with specific embodiment:

[0019] A kind of pasty silver brazing flux, its formula is as follows (weight %):

[0020] KF 25~50%;

[0021] KHF2 15-30%;

[0022] The balance is: H 3 BO 3 .

[0023] The paste silver brazing flux is suitable for silver brazing of carbon steel, stainless steel, copper and copper alloys.

[0024] The paste silver flux needs to be configured during use, and the chemical reaction formula that reacts during configuration is:

[0025] KF+H 3 BO 3 →KBF(OH) 3 ;

[0026] KHF 2 +H 3 BO 3 →K 2 [(OH)F 4 B 3 o 3 ]+5H 2 O;

[0027] The reaction product: KBF(OH) 3 and K 2 [(OH)F 4 B 3 o 3 ] is the final composition of the paste silver solder.

[0028] In the preferred embodiment of the present invention, it consists of:

[0029] KF 32%

[0030] KHF 2 18%

[0031] h 3 BO 3 50%.

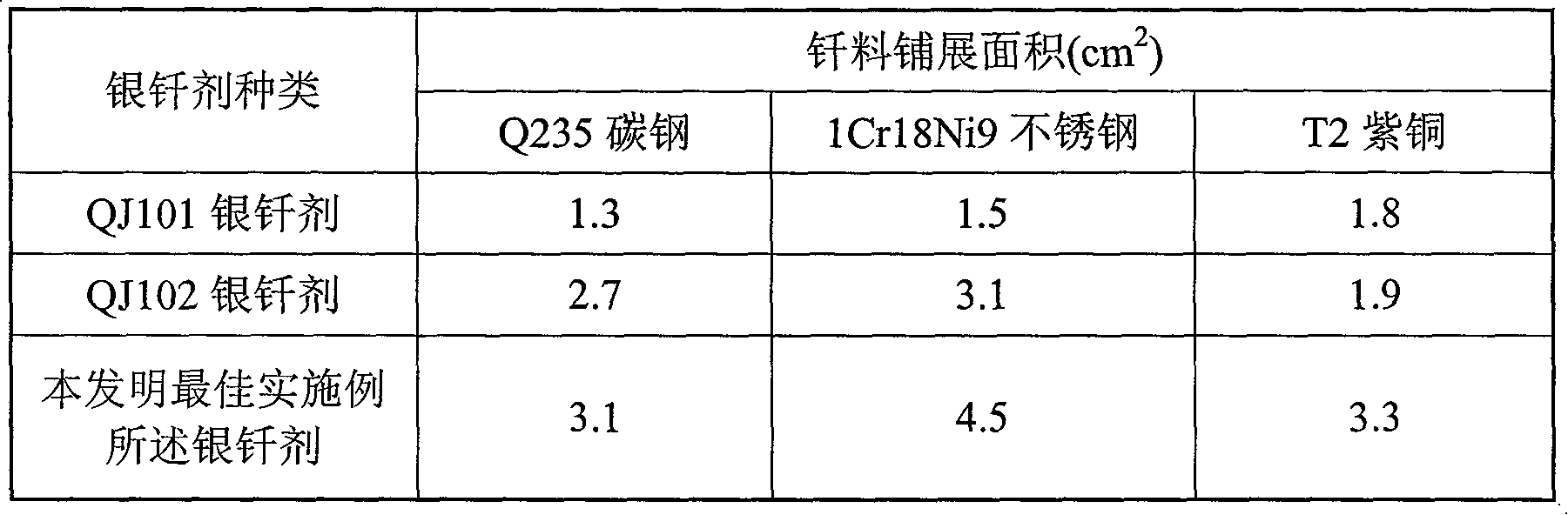

[0032] Measure the spreading area of the above-mentioned silver brazing flux fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com