Composition for changing and improving property of fiber surface and paper making method

A fiber surface and composition technology, which is applied in the field of biological enzymes and the use of biological enzymes to change fibers, can solve the problems of increased fiber loss rate, increased production cost, decreased strength, etc., and can improve physical strength, improve binding force, and change beating performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

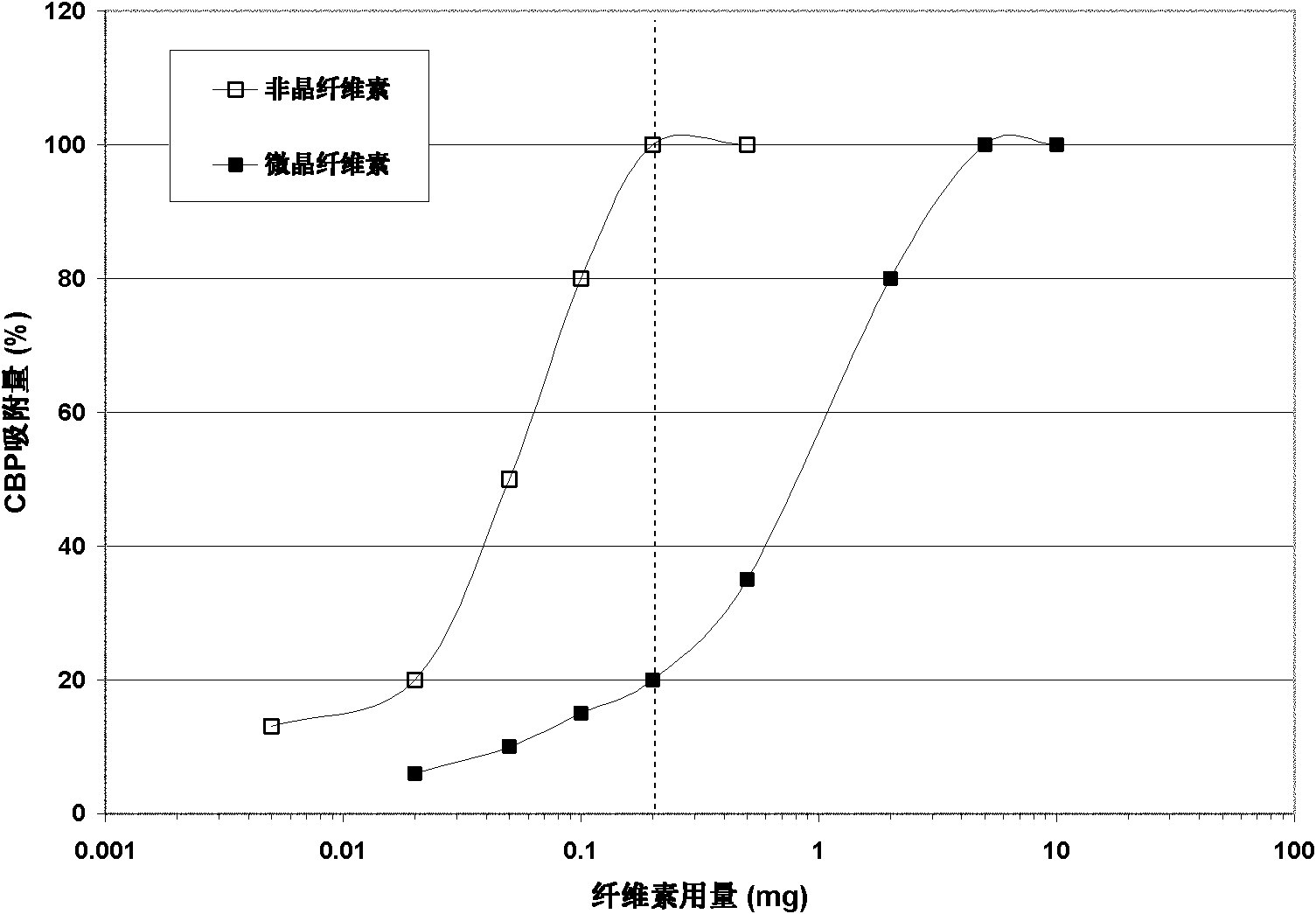

[0057] Example 1: Selective adsorption of CBP on cellulose surface.

[0058] Material : Microcrystalline cellulose and cellulose-binding protein (CBP) were purchased from SigmaAldrich. Among them, CBP (SigmaAldrich product number C8581) is a fragment with a molecular weight of 17 kDa extracted from the cellulose mixture of Clostridium cellulovorans, expressed by Escherichia coli (E. Coli). Microcrystalline cellulose is Sigma Aldrich S3504. Amorphous cellulose is prepared from microcrystalline cellulose according to the method described by Schroeder et al. (Schroeder L., Gentile V and Atalla R., "Nondegradative preparation of amorphous cellulose", IPC Technical Paper Series 15, 1985.15pp).

[0059] Adsorption measurement method : First add 0.50mg of microcrystalline or amorphous cellulose into a microcentrifuge test tube containing pH buffer solution, mix until the cellulose is evenly dispersed, then add 1-15 μg of high-purity CBP protein into the test tube, and then add p...

Embodiment 2

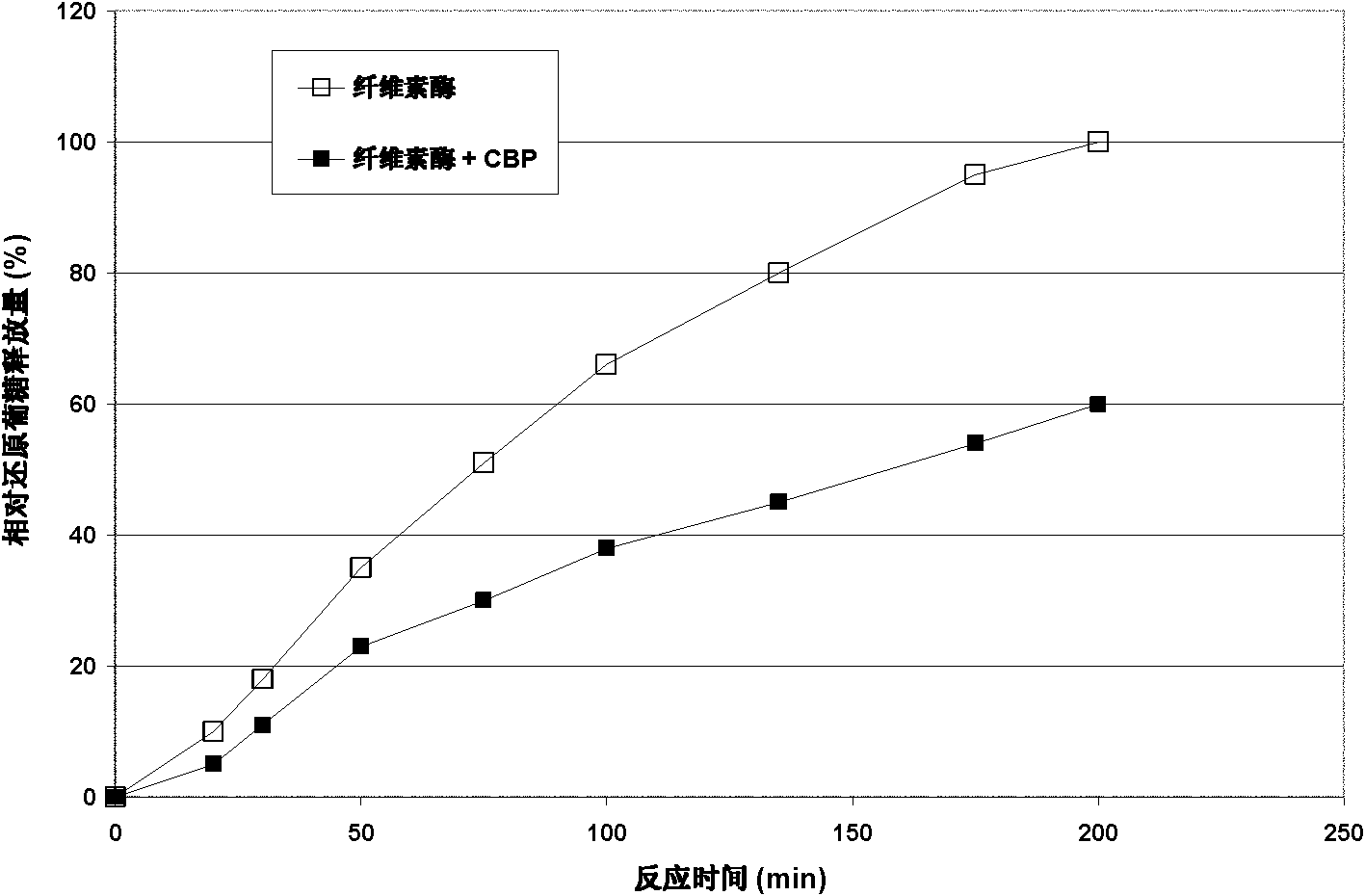

[0061] Example 2. Effect of CBP on cellulase degradation of cellulose.

[0062] Materials: CBP (SigmaAldrich Product No. C8581) is a fragment with a molecular weight of 17 kDa extracted from the cellulose mixture of Clostridium cellulovorans, expressed by E. coli (E. Coli). Microcrystalline cellulose was SigmaAldrich S3504. The cellulase was SigmaAldrich C2730 (Trichoderma reesei ATCC 26921). Method: first add 0.50 mg of microcrystalline cellulose and 0.5 mg of amorphous cellulose into a microcentrifuge test tube containing a pH buffer solution, and mix until the cellulose is evenly dispersed. For the conditional test of CBP adsorption, 15 μg of CBP protein was added to the test tube, and then the pH buffer was added to 100 μl, and the test tube was placed in a constant temperature water tank at 25°C, and mixed for 1 hour. Then add cellulase (3--200μg), mix again for 0-200 minutes, and finally use a high-speed centrifuge to separate at a centrifugal speed of 12,000g for 5 mi...

Embodiment 3

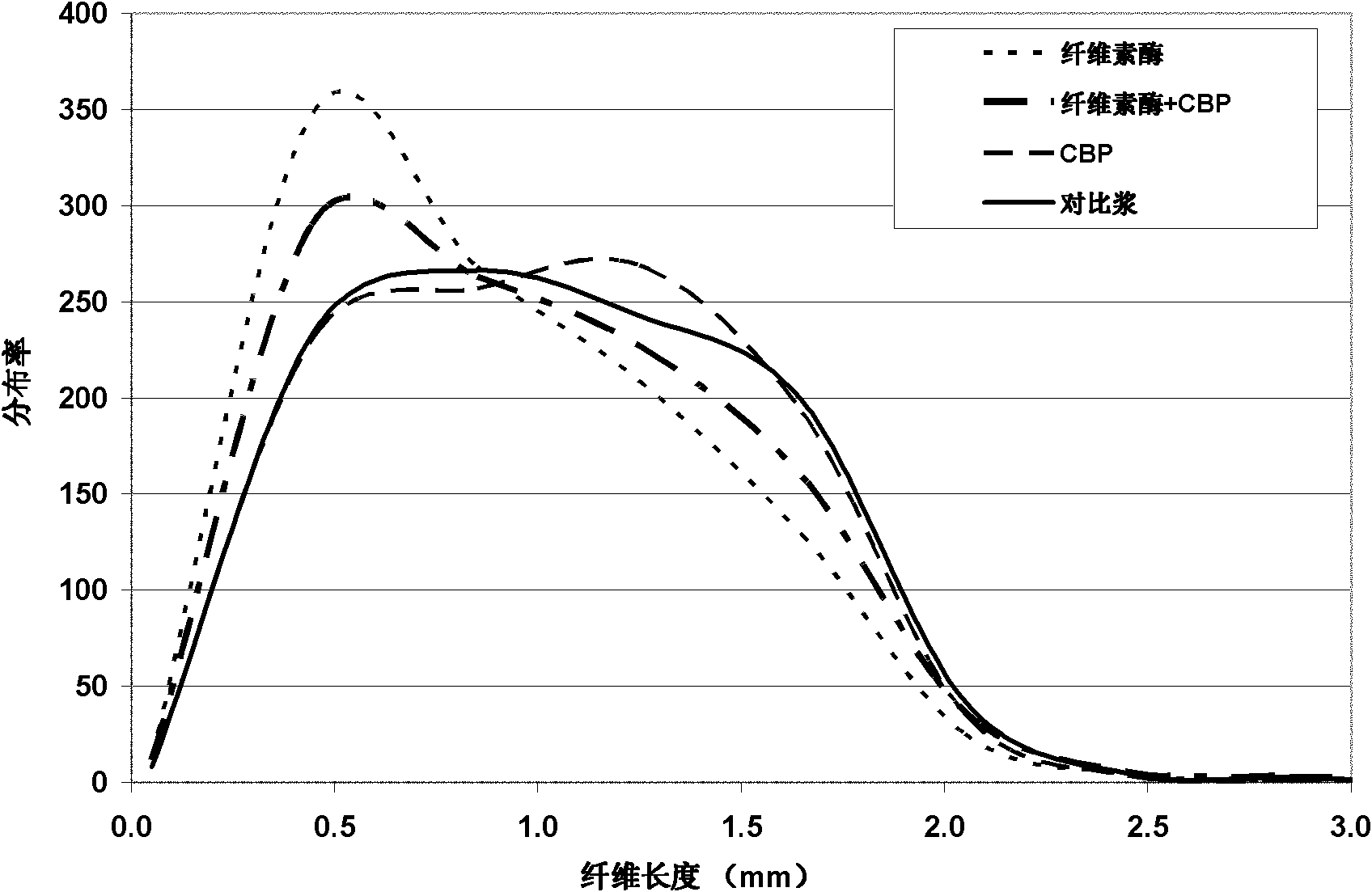

[0067] Example 3: Fiber protection of CBP in the treatment of bleached wood pulp with cellulase enzymes.

[0068] Preparation of test materials: Bleached northern American hardwood kraft chemical pulp was obtained from a paper mill in the northern United States. The puree concentration is 10%, and the whiteness is 90% ISO. Before use, the concentration of the slurry is adjusted to 1.0%, and the pH is adjusted to 6.0-6.5. CBP is Sigma Aldrich product (No. C8581), cellulase is Novozymes company's 342, which is a mixed enzyme such as endoglucanase, exoglucanase and hemicellulase.

[0069] CBP and biological enzyme reaction conditions: get 200 grams of the prepared slurry (1% concentration) above, put it into a mixing agitator, and control the temperature of the slurry at 50° C. with a thermostatic controller. Control sample: do not add any medicament, mix and stir for 10 hours; CBP process: add a certain amount (500 g / ton dry slurry) CBP protein, mix and stir for 10 hours the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com