Manufacturing method of beverage drinking straw paper

A manufacturing method and a straw technology, applied in the field of papermaking, can solve the problems of difficult natural degradation of plastics, in the research and development stage, environmental pollution, etc., and achieve the effects of smooth surface, uniform banner, and improved paper evenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

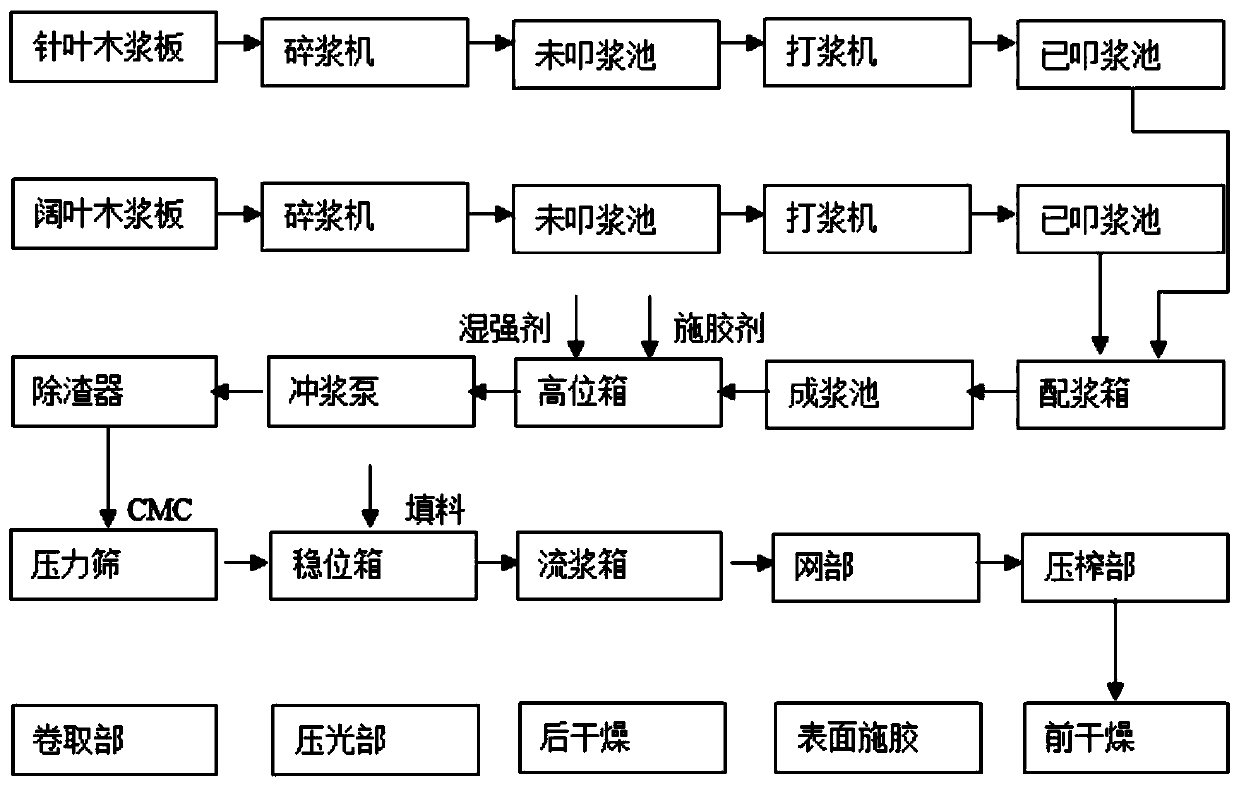

Method used

Image

Examples

Embodiment 1

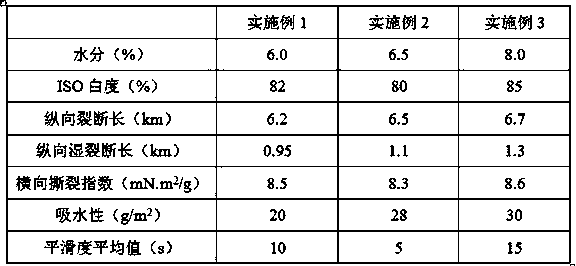

[0022] Example 1: 120 grams of straw paper

[0023] First use a pulper to pulp bleached kraft softwood pulp and bleached kraft hardwood pulp respectively, and then beat to 46°SR and 37°SR respectively, with a beating concentration of 3.0%, and bleach kraft needles at 40%. Leaf wood pulp and 60% bleached kraft hardwood pulp are mixed to obtain pulp, and the pulp is pumped from the pulping tank to the high level box, and then 0.5% of AKD glue and 4.0% of wet strength agent are added in the auxiliary materials, and the punching Slurry pump pumps it into the slag remover, after the slag is removed, it is sent to the pressure screen, and CMC0.40% is added to the inlet of the pressure screen; then the mixed slurry is transported to the stabilization box, and 6% light calcium + heavy calcium is added to mix After uniformity, it is sent to the headbox. The opening of the lip of the headbox is 13.0mm. Double-sided dehydration is carried out by overlapping the net to ensure that the fib...

Embodiment 2

[0025] Example 2: 120 grams of straw paper

[0026] First use a pulper to pulp bleached kraft softwood pulp and bleached kraft hardwood pulp respectively, and then beat to 43°SR and 36°SR respectively, with a beating concentration of 4.0%, and bleach kraft needles at 43%. Leaf pulp and 57% bleached kraft hardwood pulp were blended to obtain pulp, and the pulp was pumped from the pulping tank to the high-level box, and then 0.8% of AKD glue and 3.0% of wet strength agent were added in the auxiliary materials, and the punching Slurry pump pumps it into the slag remover, after removing the slag, it is sent to the pressure screen, and CMC0.36% is added to the inlet of the pressure screen; then the mixed slurry is transported to the stabilization box, and 6% light calcium + heavy calcium is added to mix After uniformity, it is sent into the headbox. The opening of the lip of the headbox is 12.0mm. Double-sided dehydration is carried out by overlapping the net to ensure that the fib...

Embodiment 3

[0028] Example 3: 120 grams of straw paper

[0029]First use a pulper to pulp bleached kraft softwood pulp and bleached kraft hardwood pulp respectively, and then beat to 47°SR and 33°SR respectively, with a beating concentration of 3.5%, and bleach kraft needles at 45%. Leaf pulp and 55% bleached kraft hardwood pulp are mixed to obtain pulp, and the pulp is pumped from the pulping tank to the high level box, and then 1.0% of AKD glue and 3.5% of wet strength agent are added in the auxiliary materials. Slurry pump pumps it into the slag remover, after the slag is removed, it is sent to the pressure sieve, and CMC0.35% is added to the pressure sieve inlet; then the mixed slurry is transported to the stabilization box, and 6% light calcium + heavy calcium is added After mixing evenly, send it to the headbox. The opening of the lip of the headbox is 12.8mm. Double-sided dehydration is carried out by overlapping the net to ensure that the fibers are evenly dispersed, and the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com