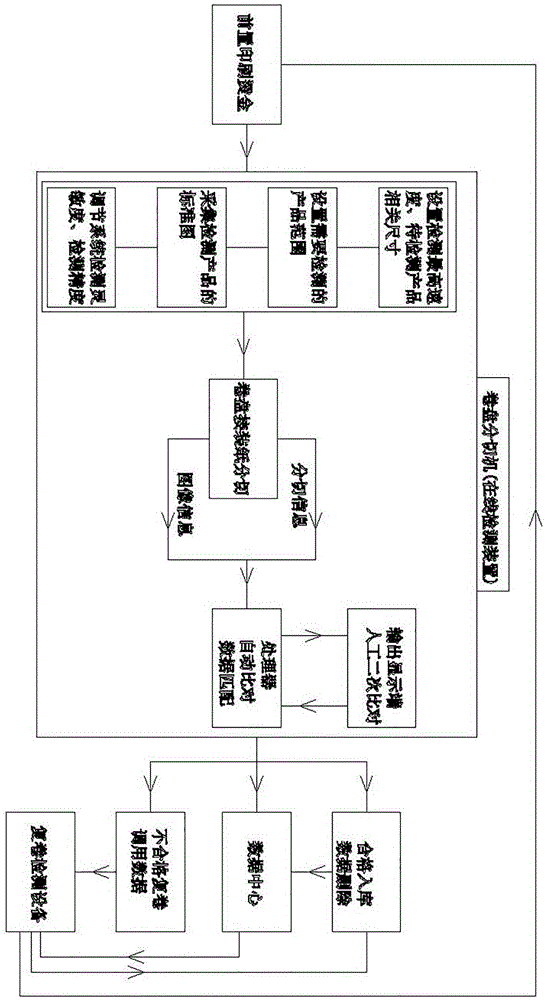

Tipping paper quality test warning system and on-line quality test method

A tipping paper and quality technology, which is applied in the direction of optical testing for flaws/defects, can solve problems that affect product quality, reduce production efficiency, and inaccuracy, and achieve the effects of improving product qualification rate, improving product quality, and fine and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

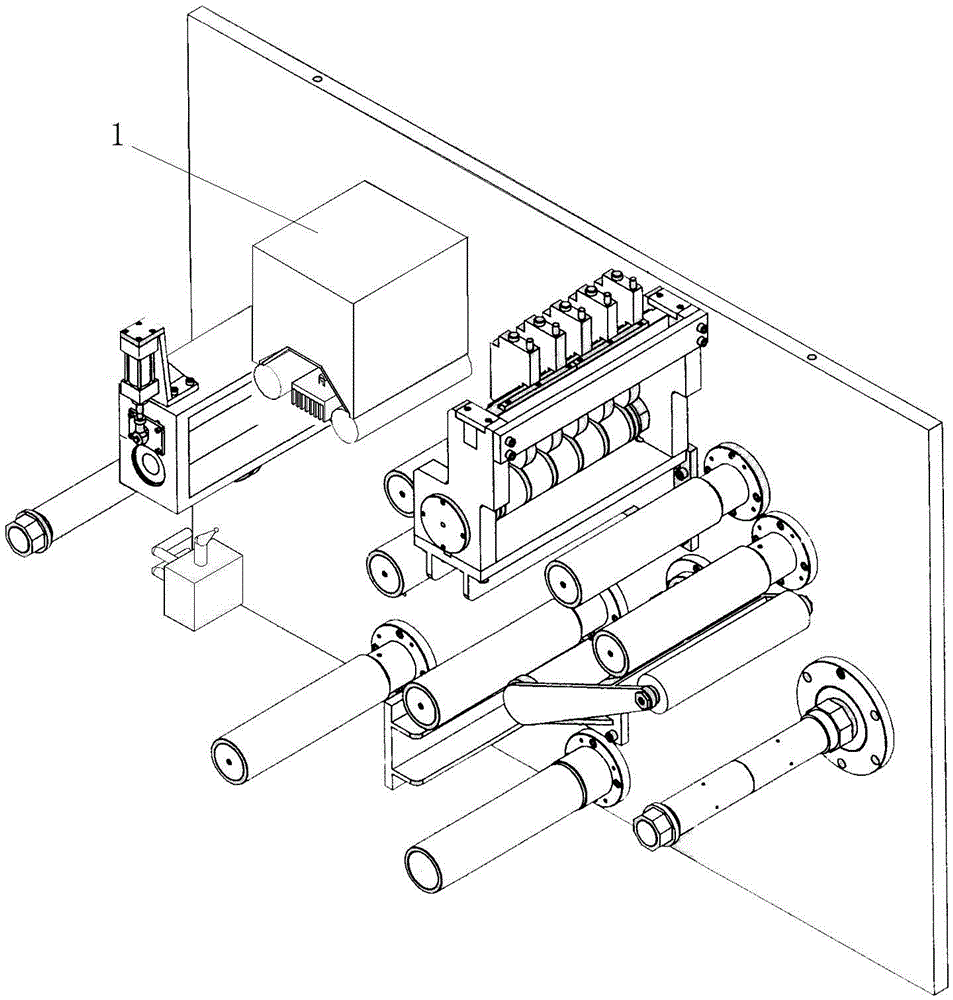

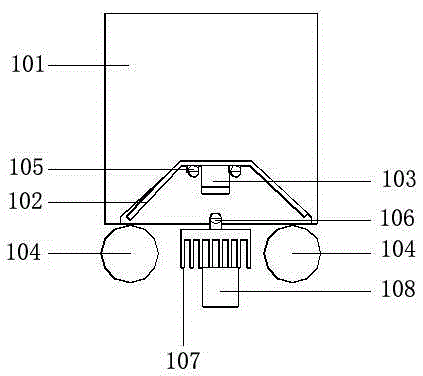

Image

Examples

Embodiment 1

[0046] like Figure 4 , Figure 5 and Image 6 As shown, the above-mentioned system and method are used for production. The product is a cigarette tipping paper of a certain brand produced in the summer night shift. There are insect clipping defects in channel 1 and channel 4 respectively. After detection, identification and elimination, it is a qualified product, and the defects are analyzed The main reason is that the doors and windows of the production workshop were closed tightly in summer. After management coordination, the problem of trapping insects has been greatly improved.

Embodiment 2

[0048] like Figure 7 As shown, the above-mentioned system and method are used for production. The product is a cigarette tipping paper of a certain brand. This product is more likely to have the problem of missing stamping in the later stage of the same batch of production tasks. After detection, identification and elimination, it is a qualified product. The reason for the analysis of the defects is that the anodized aluminum used in the bronzing process has been repeatedly used, and some anodized aluminum has quality problems. After the supervision of relevant personnel, the problem has been successfully solved.

Embodiment 3

[0050] like Figure 8 As shown, the above-mentioned system and method are used for production. The product is a cigarette tipping paper of a certain brand. There are many dirty spots in the product. After detection, identification and elimination, it is a qualified product. The cause of the defect is analyzed in the printing process. The ink roller brush was worn out, which caused the ink to splash on the paper. After coordinating the replacement of the ink roller, the problem was successfully solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com