Needle pulp and broad leaf pulp pretreatment method with neutral cellulase

A kind of neutral cellulase, softwood pulp technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

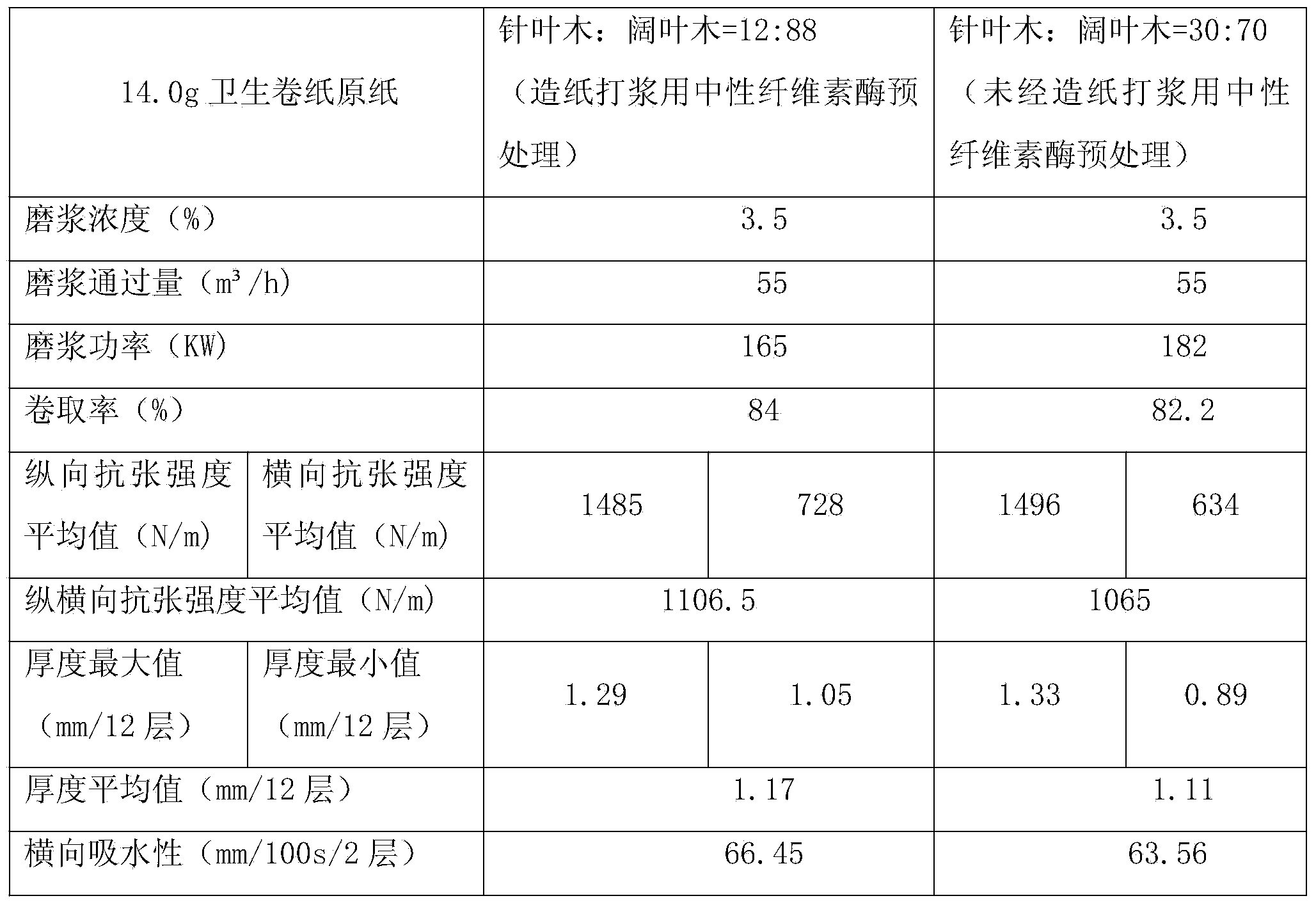

Examples

Embodiment 1

[0026] The method for neutral cellulase pretreatment softwood pulp and hardwood pulp, comprises the following steps:

[0027] (1) Add 1 / 3 volume of pulping water into the medium-consistency hydraulic pulper tank. The pH value of the pulping water is 6.5-7.0, and the water temperature is 40-45°C. When the water temperature is lower than 40°C, use a drying Cylinder exhaust steam heats pulping water;

[0028] (2) Start the medium-consistency hydraulic pulper, add thermophilic Chaetomium cellulase for papermaking beating to the medium-consistency hydraulic pulper, and the dosage is 0.2kg of thermophilic wool for papermaking pulping per ton of pulp. For shell fungus cellulase, put the coniferous pulp and broad-leaved pulp into the medium-concentration hydraulic pulper at a ratio of 12:88, and keep the thermophilic Chaetomium cellulase and pulp in the medium-concentration hydraulic pulper for papermaking pulping. The reaction time in the pulper is 30 minutes;

[0029] (3) The pret...

Embodiment 2

[0032] The method for neutral cellulase pretreatment softwood pulp and hardwood pulp, comprises the following steps:

[0033] (1) Add 1 / 3 volume of pulping water into the medium-consistency hydraulic pulper tank. The pH value of the pulping water is 6.5-7.0, and the water temperature is 40-45°C. When the water temperature is lower than 40°C, use a drying Cylinder exhaust steam heats pulping water;

[0034] (2) Start the medium-consistency hydraulic pulper, add thermophilic Chaetomium cellulase for papermaking beating to the medium-consistency hydraulic pulper, and the dosage is 0.1kg of thermophilic wool for papermaking beating per ton of pulp. For shell fungus cellulase, put the coniferous pulp and broad-leaved pulp into the medium-concentration hydraulic pulper at a ratio of 12:88, and keep the thermophilic Chaetomium cellulase and pulp in the medium-concentration hydraulic pulper for papermaking pulping. The reaction time in the pulper is 35 minutes;

[0035] (3) The pret...

Embodiment 3

[0038] The method for neutral cellulase pretreatment softwood pulp and hardwood pulp, comprises the following steps:

[0039] (1) Add 1 / 3 volume of pulping water into the tank body of the low-consistency hydraulic pulper. The pH value of the pulping water is 6.5-7.0, and the water temperature is 40-45°C. When the water temperature is lower than 40°C, use an oven Cylinder exhaust steam heats pulping water;

[0040] (2) Start the low-consistency hydraulic pulper, add thermophilic Chaetomium cellulase for papermaking beating to the low-consistency hydraulic pulper, and the dosage is 0.3kg of thermophilic wool for papermaking pulping per ton of pulp. For shell fungus cellulase, put the coniferous pulp and broad-leaved pulp into the medium-consistency hydraulic pulper at a ratio of 12:88, and keep the thermophilic Chaetomium cellulase and pulp used for pulping in low-concentration hydraulic pulverization. The reaction time in the pulper is 35 minutes;

[0041] (3) The pretreated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com