Preparation method of high-performance wear-resistant paper

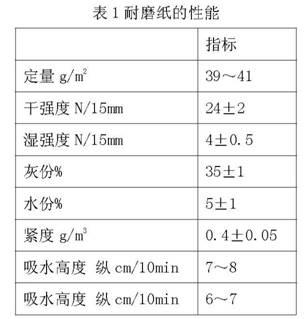

A wear-resistant paper, high-performance technology, applied in pulp beating method, paper, papermaking, etc., can solve the problems of reduced transparency, white flowers, and reduced stability of wear-resistant indicators, so as to reduce consumption, improve retention rate, and improve clarity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

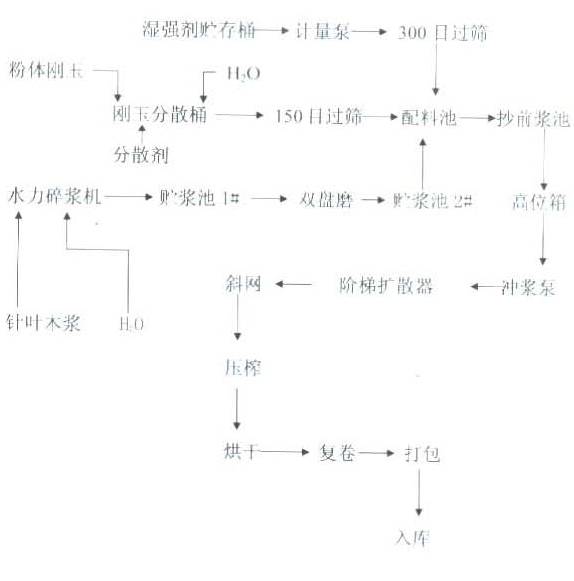

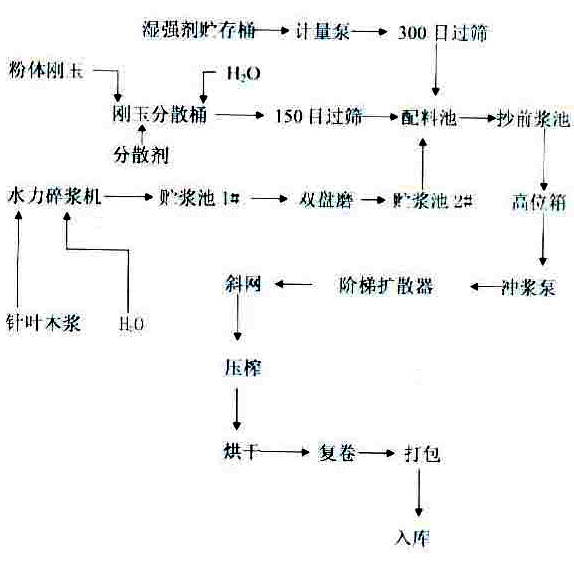

[0051] see figure 1 As shown in the process flow chart of the present invention, a method for preparing high-performance wear-resistant paper, the wear-resistant paper is made by mixing coniferous wood pulp, powdered corundum pulp and additives, then going online, pressing, and drying, wherein , including the following steps:

[0052] The first step of raw material configuration:

[0053]Powdered corundum (purity 99.5%, specific gravity 3.9-4.1g / cm 2 , the particle size is 45-106um, of which the proportion of 53-75um powder accounts for about 87% of the total weight, and the powder corundum is activated and modified by silane coupling agent), water and dispersant, including sodium hexametaphosphate and Add sodium polyacrylate (Rohm and Haas ACUMER9400) into the dispersion bucket and mix, sieve with 150 mesh, and set aside;

[0054] Measure the additive wet strength agent (Hanghua Harima ws-1) and sieve it through 300 mesh, and set aside;

[0055] The coniferous wood pulp a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com