Pasteurizable wide-mouth container

a wide-mouth, plastic container technology, applied in the direction of rigid containers, large containers, packaging, etc., can solve the problems of pet containers that are capable of being filled with volatile food products, glass containers are heavy and breakable, and no known commercially availabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

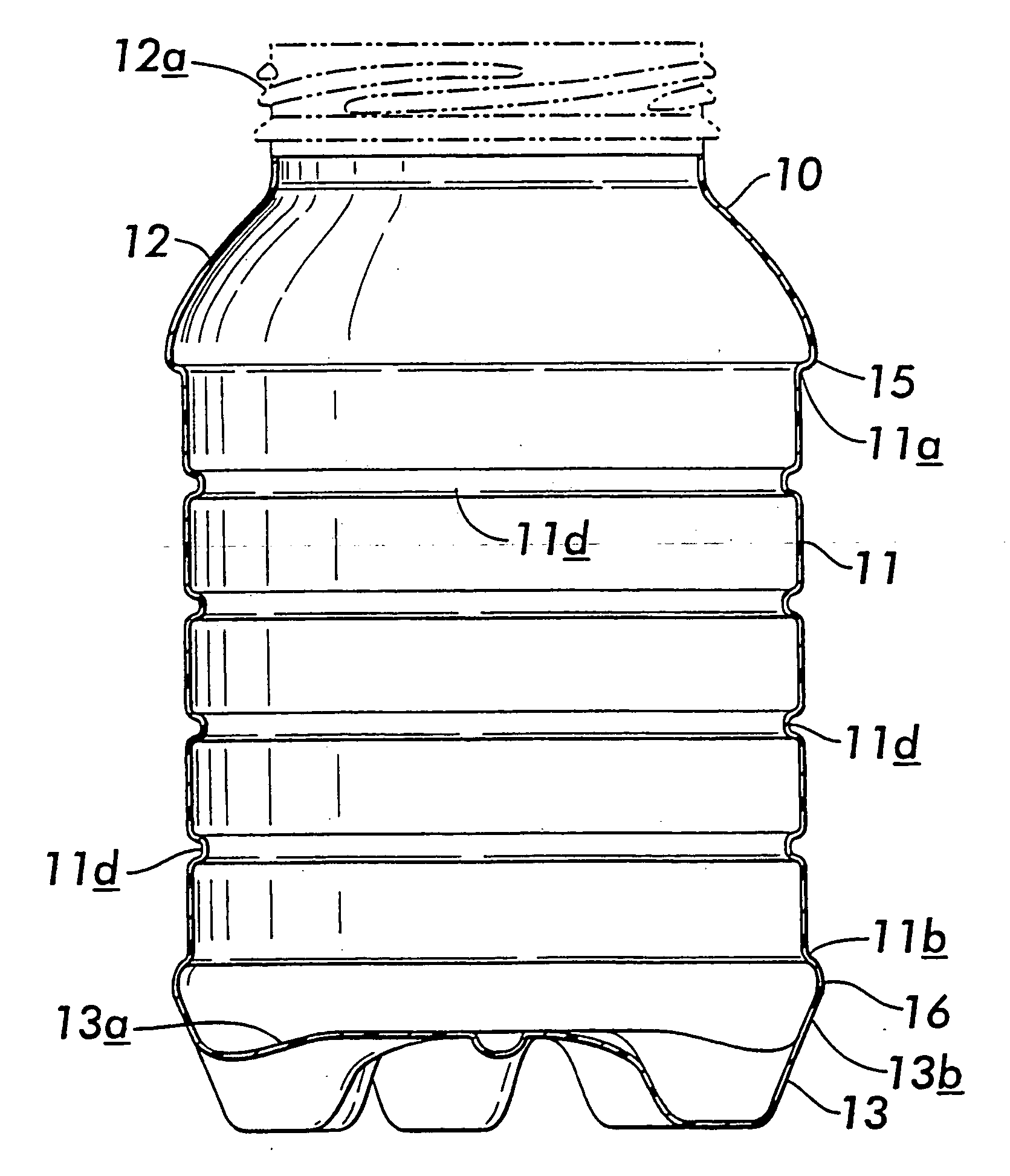

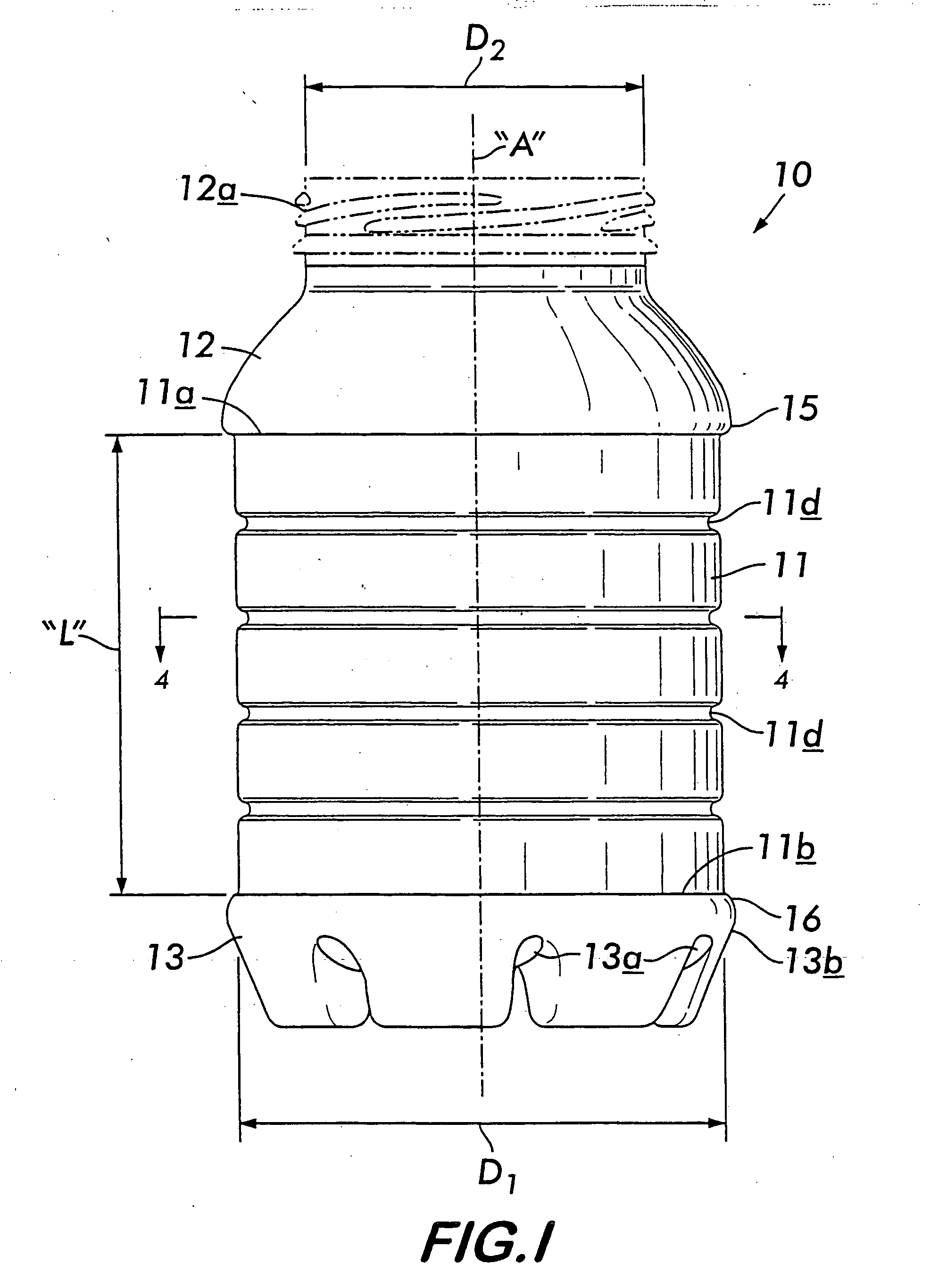

[0015] FIG. 1 illustrates a container 10 which embodies the present invention. The container 10 has a sidewall 11, a dome 12 superadjacent the sidewall 11, and a base 13 below the sidewall 11. The dome 12 has a wide-mouth, threaded finish 12a which is blow-molded such as in the manner described in U.S. Pat. No. 5,887,739, the disclosure of which is incorporated by reference wherein.

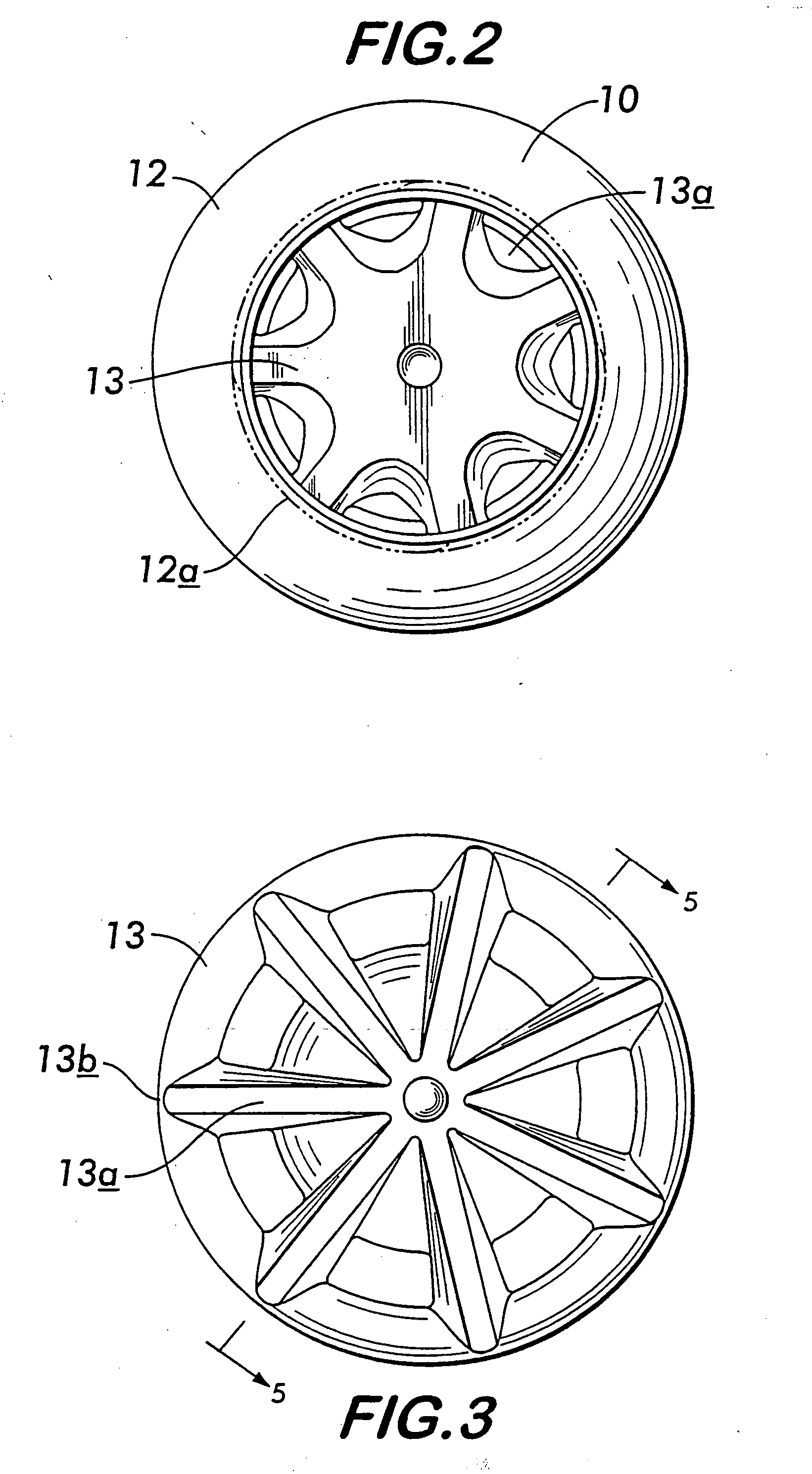

[0016] The base 13 is of conventional construction, being of a so-called footed, petaloid, pressure-resistant configuration. The base 13 includes a plurality of radially extending, downwardly concave ribs 13a which extend outwardly from the longitudinal axis "A" of the container 10 to the outer surface 13b of the base 13. The disclosed footed, petaloid base design is well known in the art and is exemplified in expired U.S. Pat. No. 3,935,955. Such bases have found particular utility in carbonated beverage containers.

[0017] The sidewall 11 is adapted to receive a conventional label. In order to protect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com