Bubble detection and recovery in a liquid pumping system

a liquid pumping system and bubble detection technology, applied in gravity filters, feed/discharge of settling tanks, loose filtering material filters, etc., can solve the problem of bubble detection desensitizes operation sensitivity to low gas compression ratio, etc. problems, to achieve the effect of enhancing reliability and maintainability of the system, reducing solvent conditioning at the input, and acceptable chromatographic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

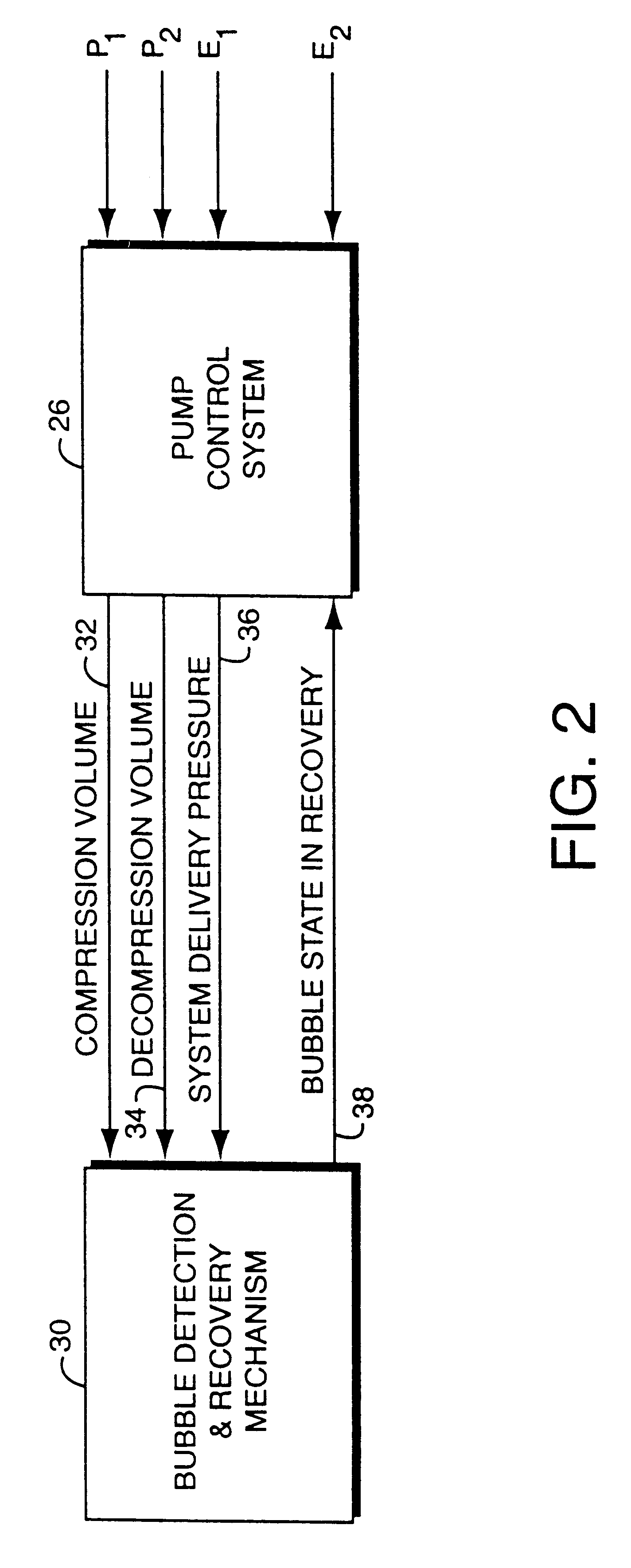

A bubble detection and recovery mechanism according to the invention detects the pressure of a bubble or significant amounts of gas in a fluid stream and performs a recovery sequence to enhance the pump's ability to expel a bubble or solvent / fluid stream having a significant gas content. The bubble detection and recovery mechanism is implemented in a solvent delivery pump system, such as is typical in High Pressure Liquid Chromatography (HPLC) applications. Upon detection of a bubble or significant amounts of gas in the fluid stream, a recovery sequence is performed without disturbing user-set flow rates and solvent composition settings.

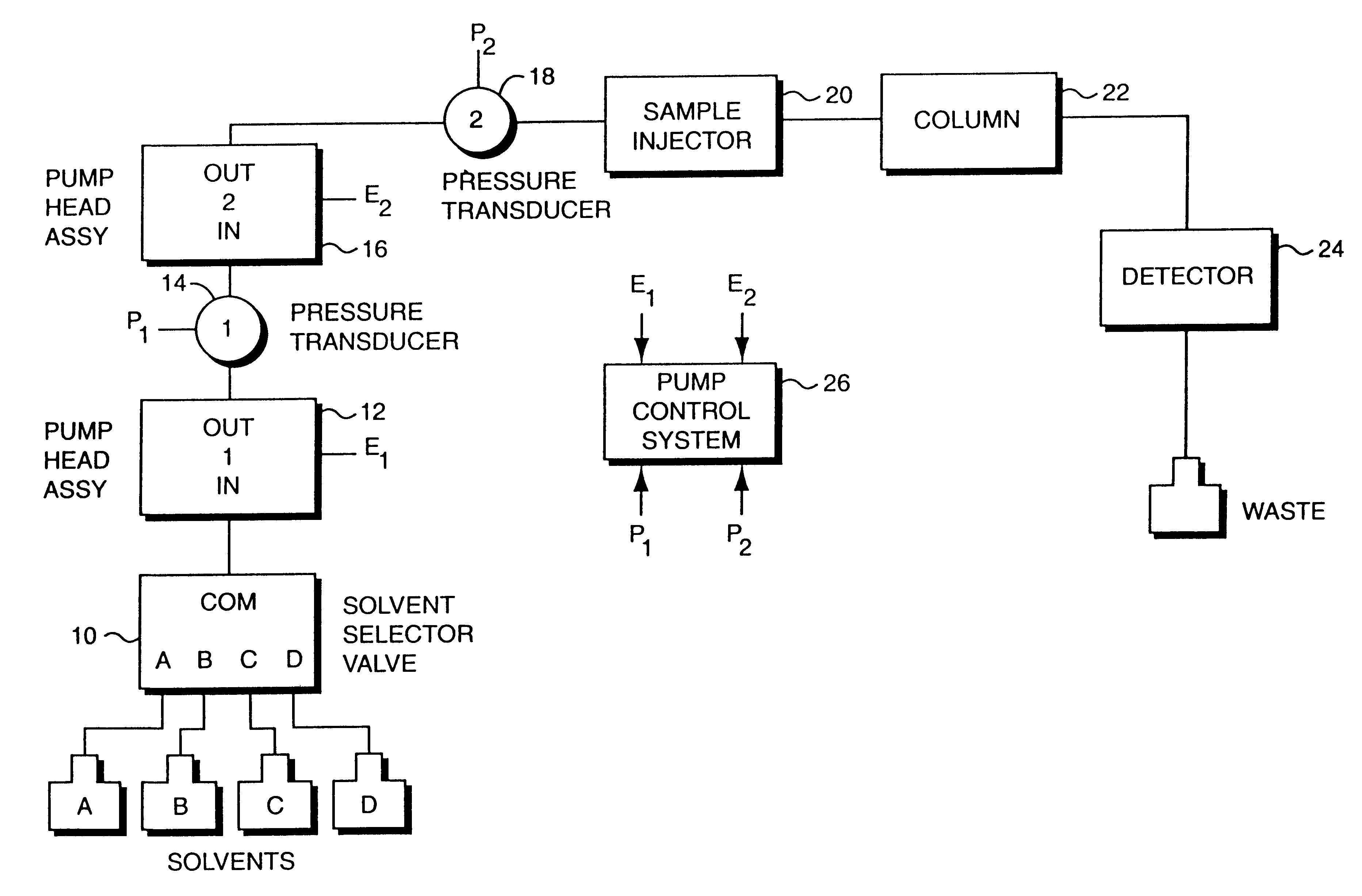

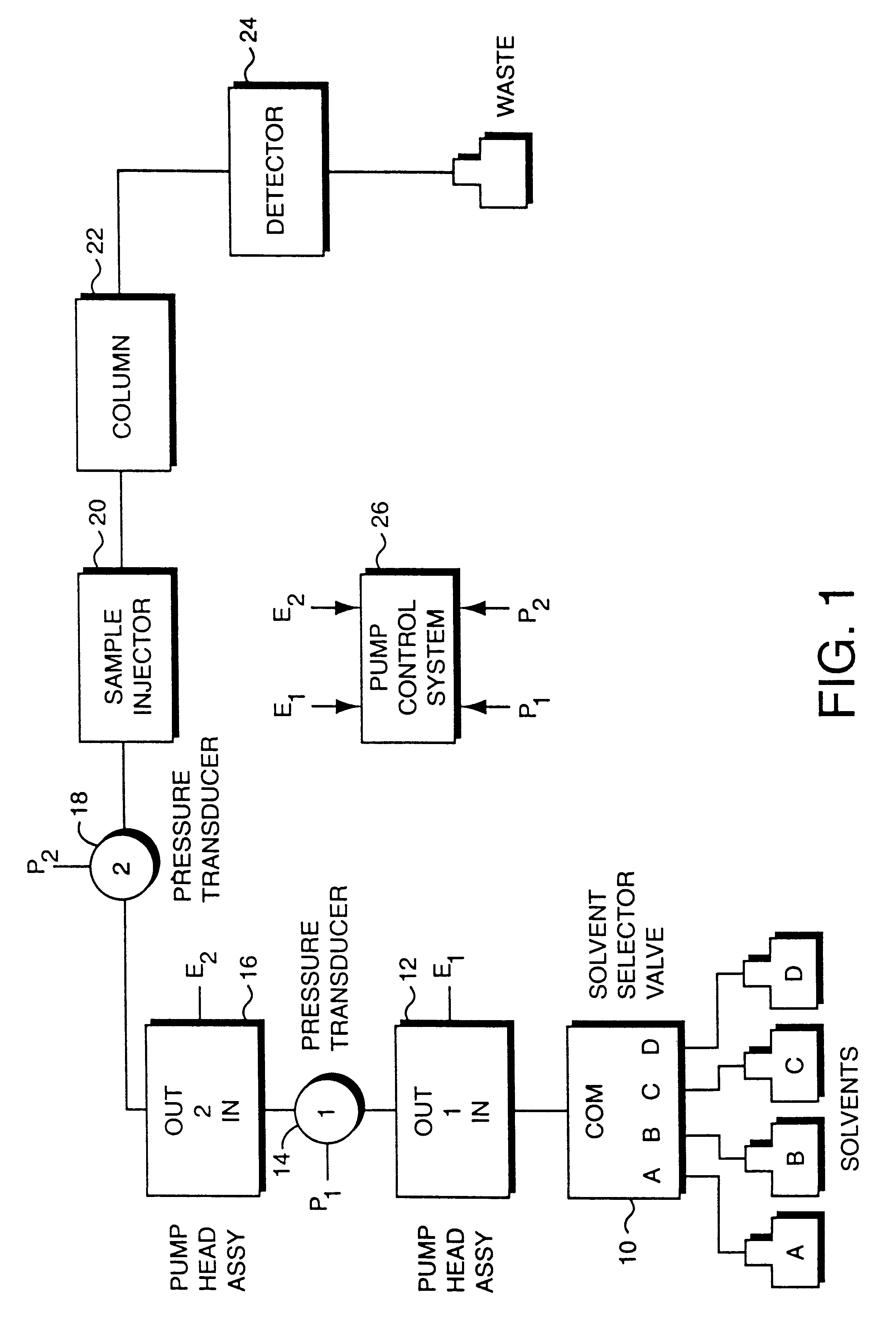

The apparatus in which the bubble detection and recovery mechanism is implemented, is a solvent delivery pump system, such as illustrated in FIG. 1, designed to meter multiple solvents and deliver a desired mixture at a desired flow rate for the purpose of performing chromatography separations of sample compounds.

As illustrated, solvent mixing is per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression volume | aaaaa | aaaaa |

| decompression volume | aaaaa | aaaaa |

| decompression volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com