Pressure Augmented Mouse

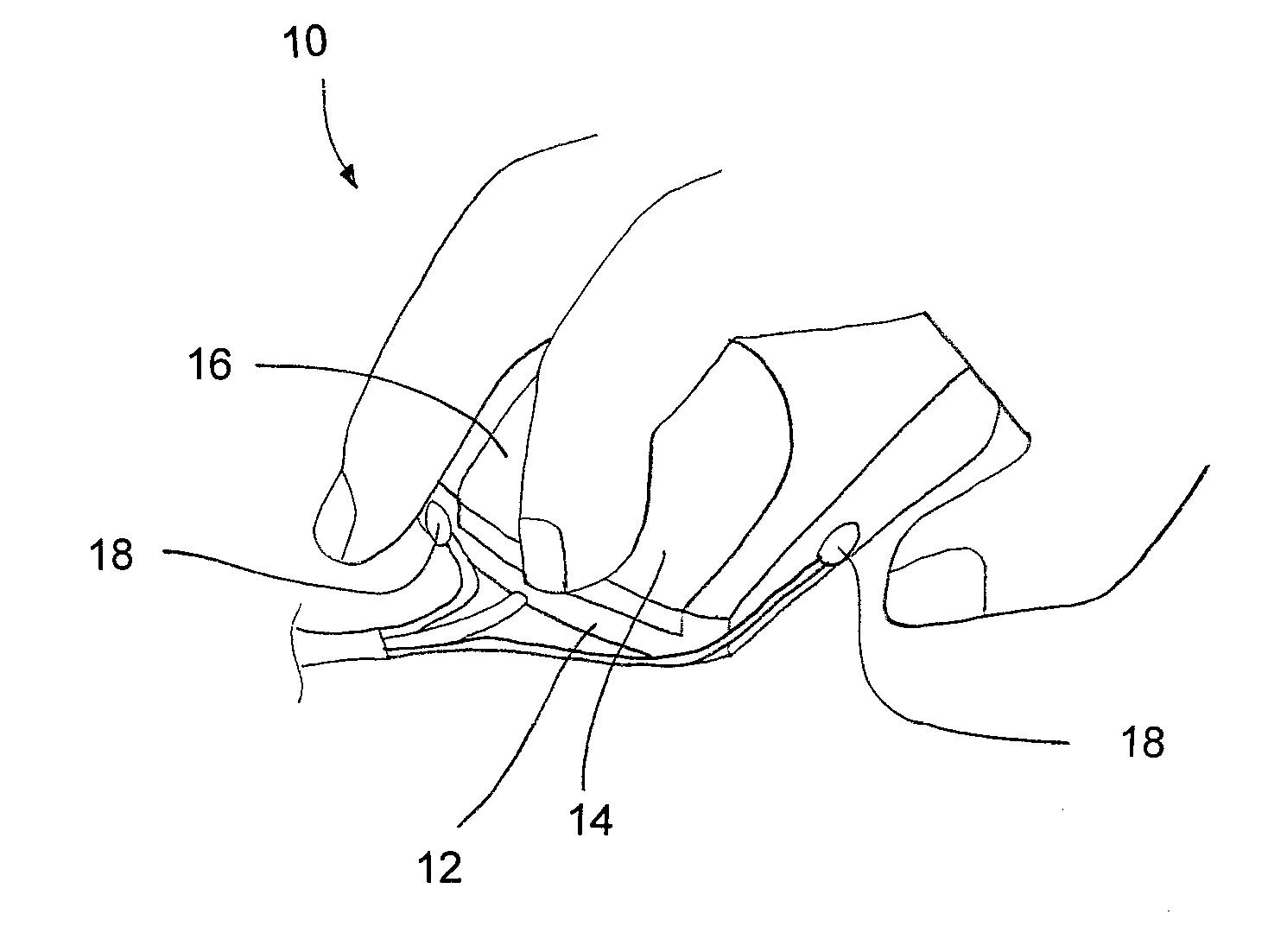

a mouse and pressure technology, applied in the field of input devices, can solve the problems of limited pressure-based input, difficult for users to benefit, and limited interaction bandwidth,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

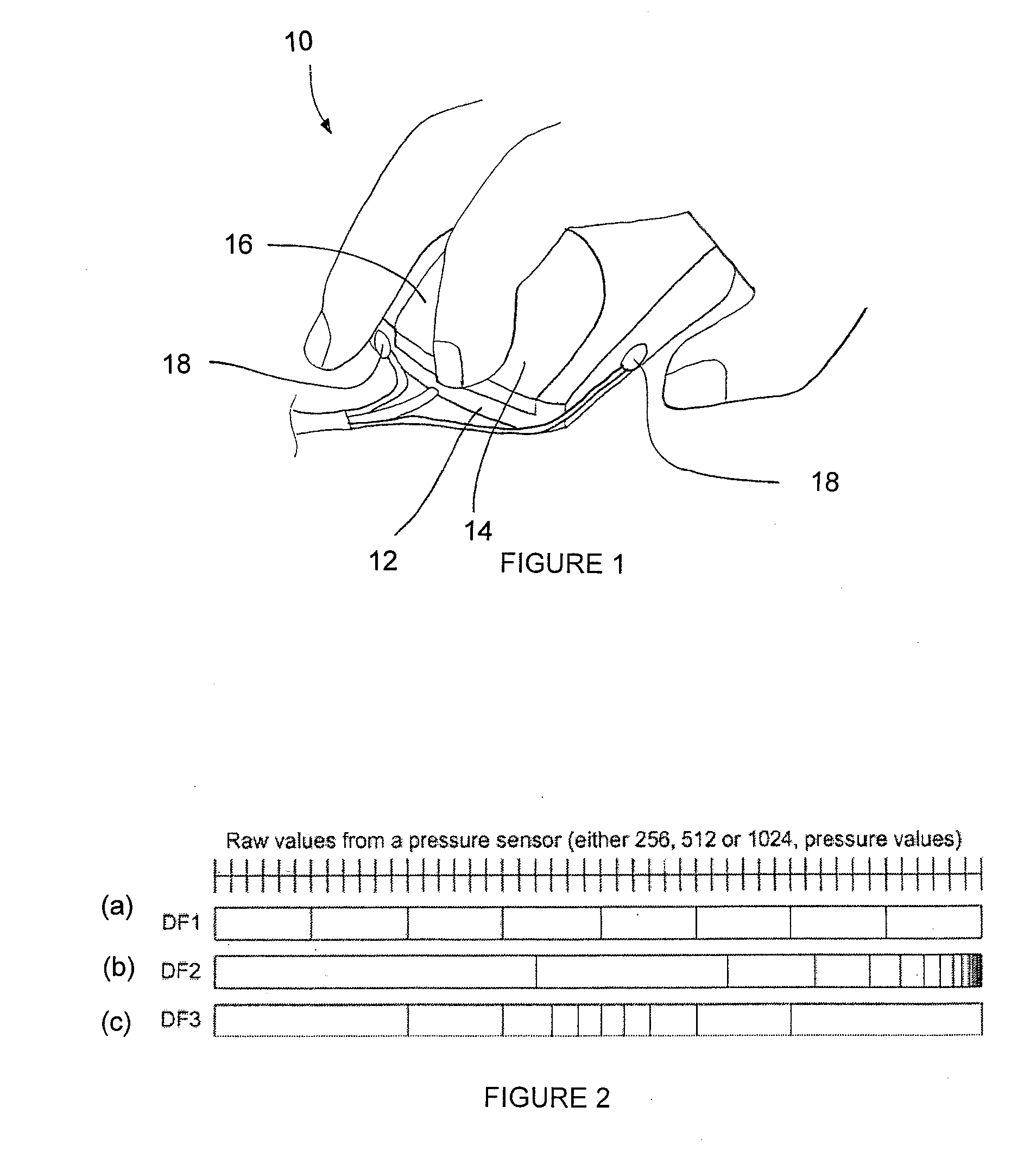

Method used

Image

Examples

experiment 1

Results of Experiment 1

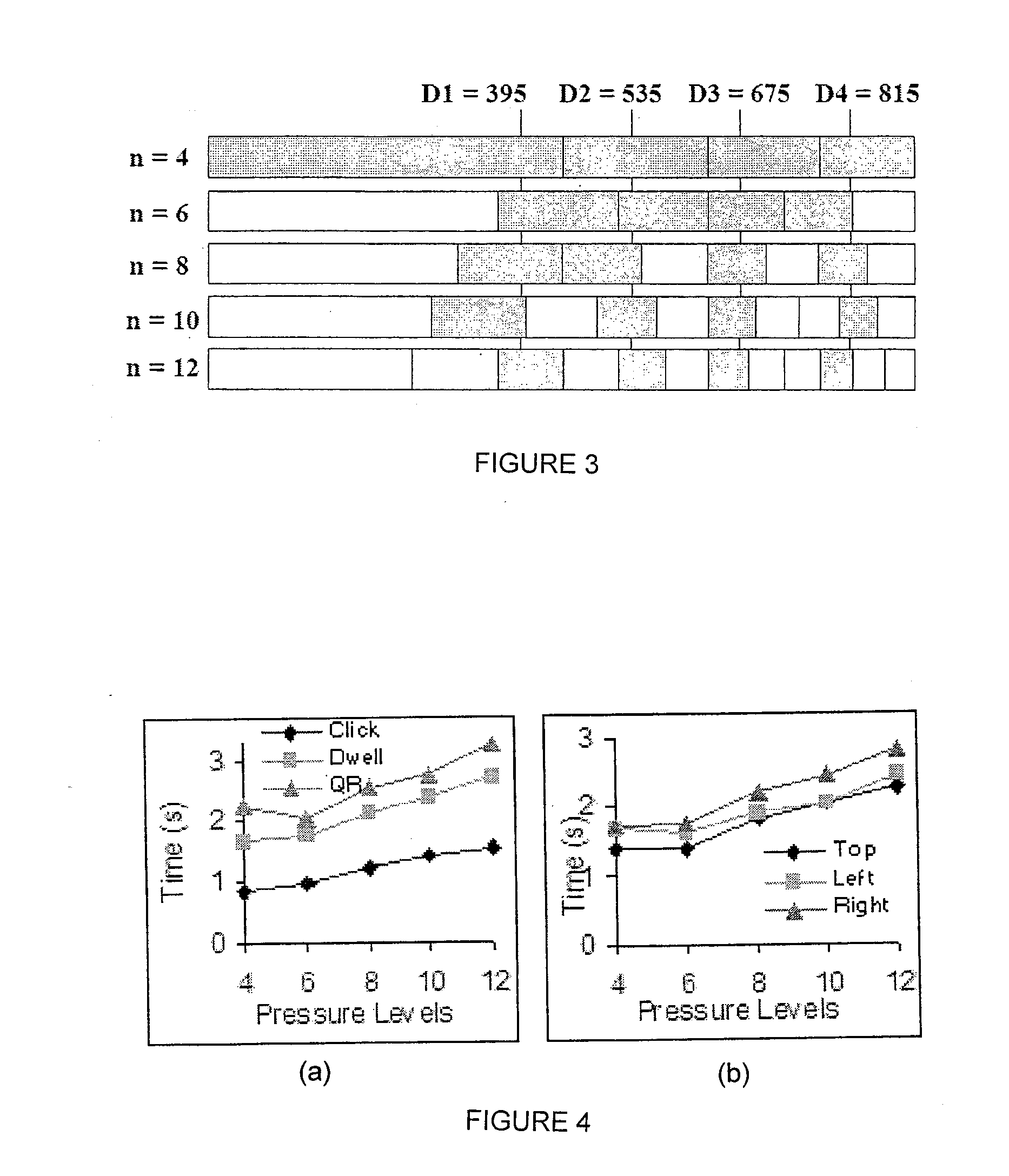

[0182]We used the univariate ANOVA test and Tannhane post-hoc pair-wise tests (unequal variances) for all our analyses. To make the data conform to the homogeneity requirements for ANOVA we used a natural-log-transform on the completion time. Results showed main effect of selection technique, sensor location, pressure-levels and target-distances (all p2,16=20.05, F2,16=4.57, F4,32=113.06, and F3,24=21.655 respectively.

[0183]Post-hoc pair-wise comparisons of pressure-levels yielded significant differences (all p<0.01) in trial completion times for all pairs except between pressure-levels 4 and 6. Users were fastest when the pressure level was 4 and slowest at pressure level 12.

[0184]Post-hoe pair-wise comparisons of selection techniques yielded significant differences (all p<0.01) in trial completion times for all pairs. Participants were fastest with click, followed by dwell and QR. FIG. 4 (left) shows the mean completion time of each technique ...

experiment 2

Results of Experiment 2

Time

[0211]The overall mean completion times across all conditions was 1.57 s (standard error=0.044 s). To make the data conform to the homogeneity requirements for ANOVA we used a natural-log transform on the completion time. Results show a main effect of Control Mechanism and Pressure-levels on trial completion times with F2,14=18.46, (p3,21=178.106, (pa0.01) respectively.

[0212]Post-hoc pair-wise comparisons of pressure-levels yielded significant differences (all p<0.o1) in trial completion times for all pairs except between pressure-levels 12 and 16. Users were fastest when the pressure level was 4 followed by 12, 16 and 64.

[0213]Post-hoc pair-wise comparisons of control-mechanisms yielded significant differences (all p<0.01) in trial completion times between Tap and Normal and Tap and Switch. We did not find any significant difference between Normal and Switch-to-Refine techniques. Users were fastest with Tap followed by Normal and Switch, FIG. 7 shows the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com