Non-sintered type thin electrode for battery, battery using same and process for same

a thin electrode, non-sintered technology, applied in the direction of cell components, electrochemical generators, transportation and packaging, etc., can solve the problems of low mechanical strength, low mechanical strength, and low mechanical strength of the entire electrode, so as to prevent the peeling of the active material layer, the effect of enhancing the active material powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0072] Next, a concrete embodiment of the present invention is described.

production example

[0073] As shown in FIG. 10, a nickel plated steel plate (plating thickness of 1 μm) having a thickness of 0.3 mm,which is punched out into a circle, is submitted to one cycle of ironing with drawing by spindle 13 in the manner known in the art so as to form a cylindrical container 14 with a bottom. More concretely, as for the dimensions the outer diameter is 14 mm, the thickness of the side walls is 0.16 mm and the thickness of the bottom is 0.25 mm. Here, it is preferable to provide thicker parts R at the border part of the inside of the case between the side walls and the bottom, in order to prevent the physical strength of the border from being weakened.

embodiment 1

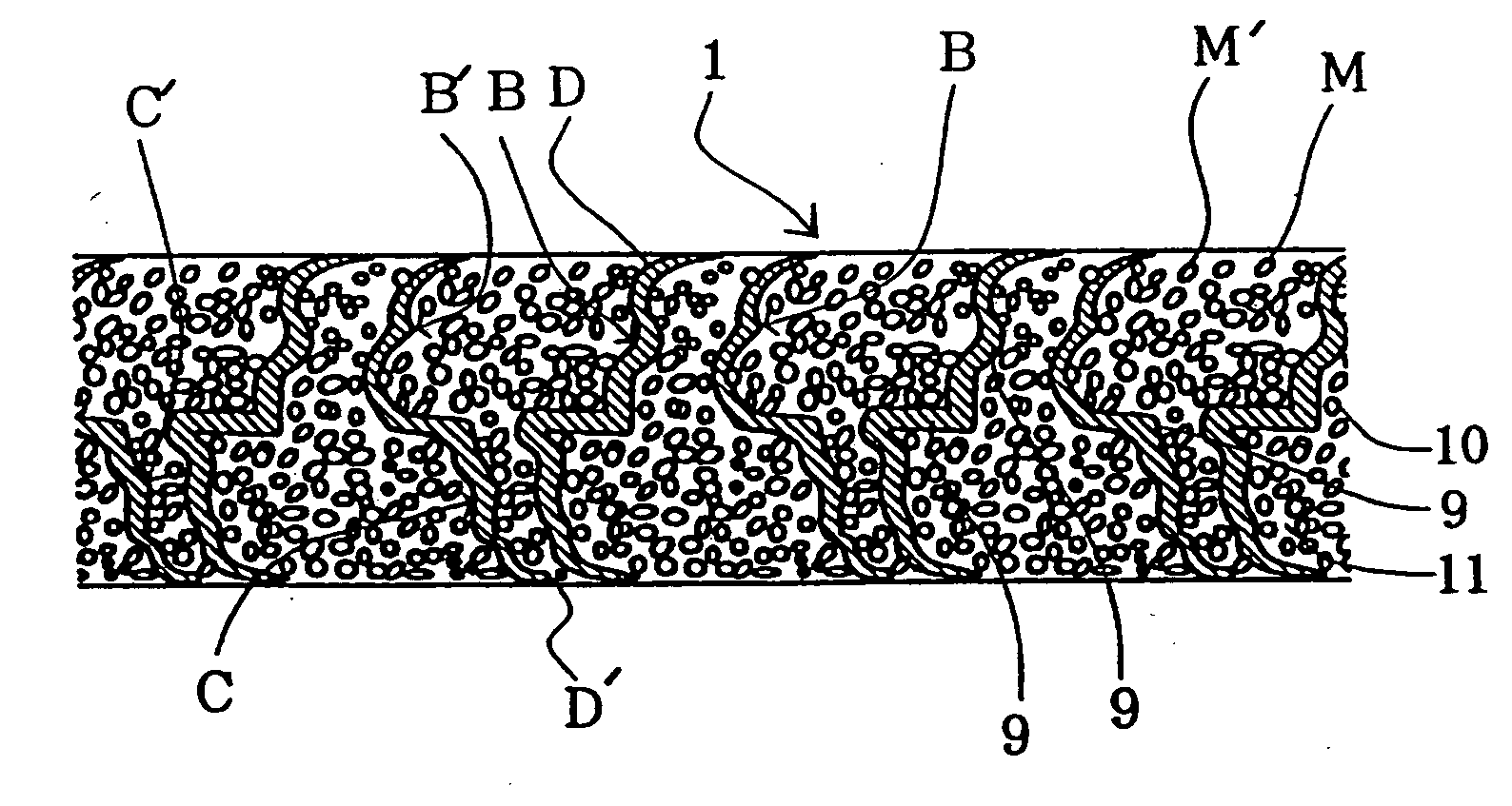

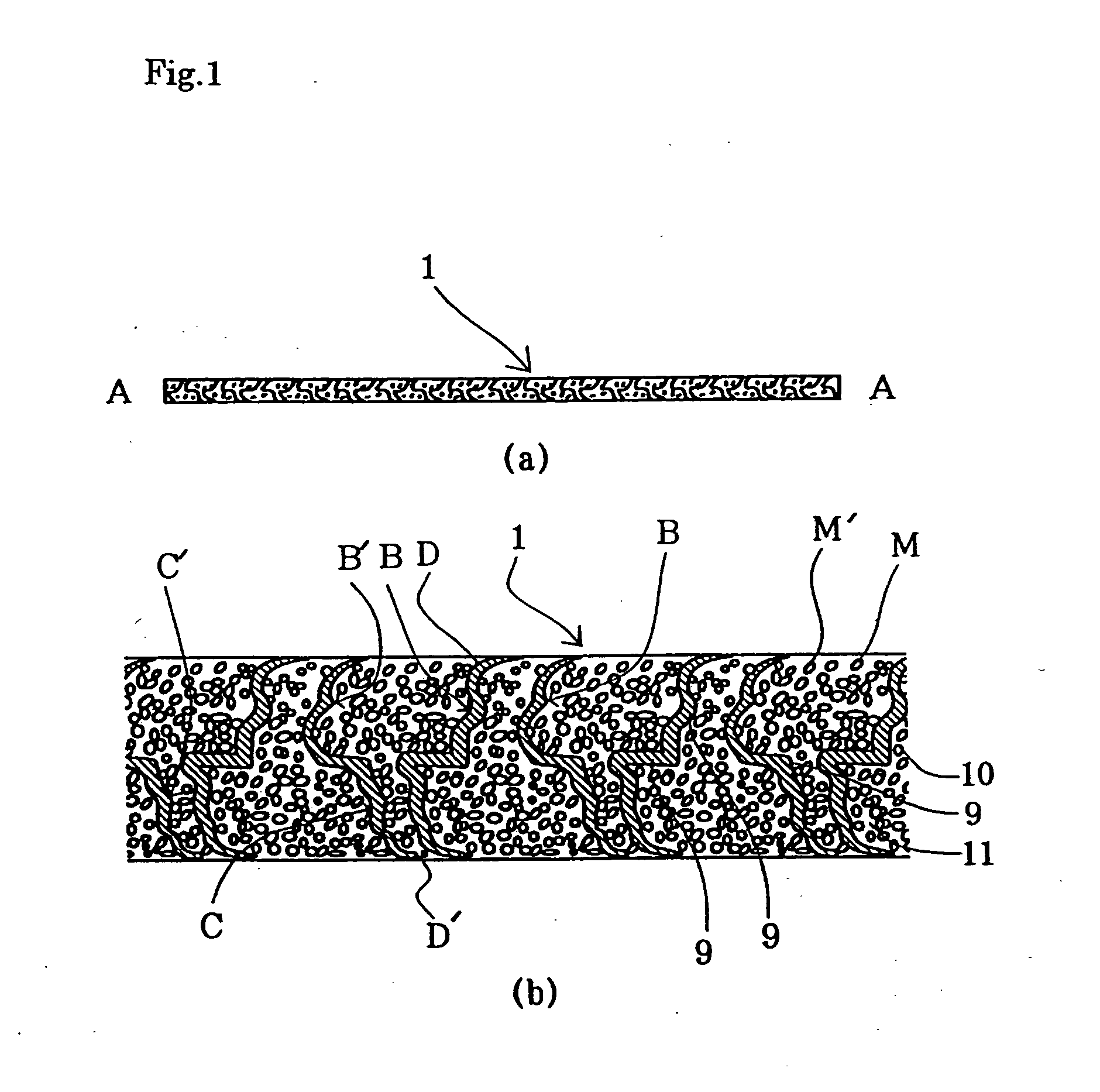

[0074] Nickel foil in a wide belt-like form, having a thickness of 30 μm, is pressed between a pair of dies (or between rollers) wherein innumerable microscopic conical concavities and convexities are formed on the surface of the both dies so that a three dimensional conductive electrode substrate having innumerable microscopic hollow chimney shapes in the nickel electrode substrate 9 of FIG. 4 is manufactured. Two examples of the possible kinds of patterns of the concave and convex parts of the nickel substrate 9 in FIG. 4 are shown in FIGS. 5(a) and 5(b) which are the partially enlarged figures of the nickel electrode substrate, wherein parts B and C in FIG. 5 indicate the convex parts and the concave parts, respectively. The closest parts to the convex parts (concave parts) in FIG. 5(a) are all concave parts (convex parts) and in FIG. 5(b) the closest parts to the convex parts (concave parts) are concave parts (convex parts) in a ration of four out of six. In the present embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com