Preparation of nano zinc powder by single groove ultrasonic electrolytic process

A technology of nano-zinc powder and ultrasound, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., to achieve the effect of easy process, good catalytic performance, and stable composition and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

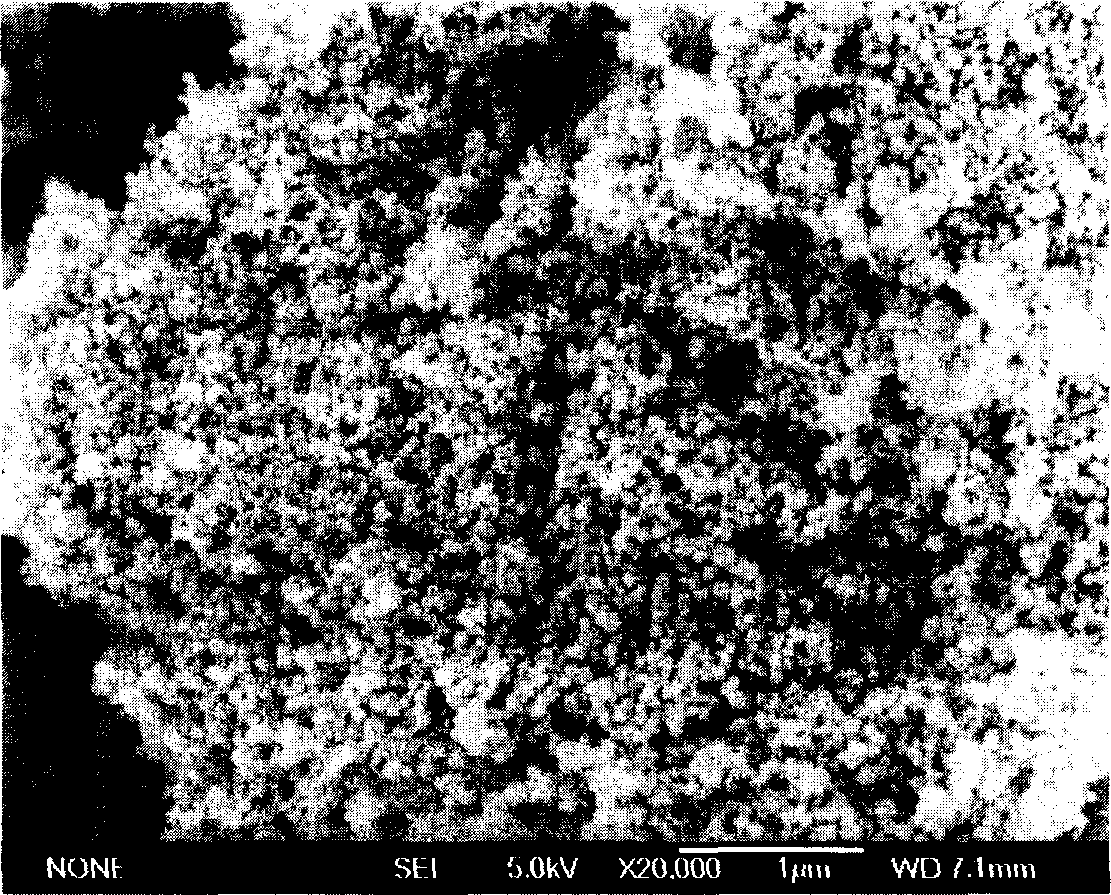

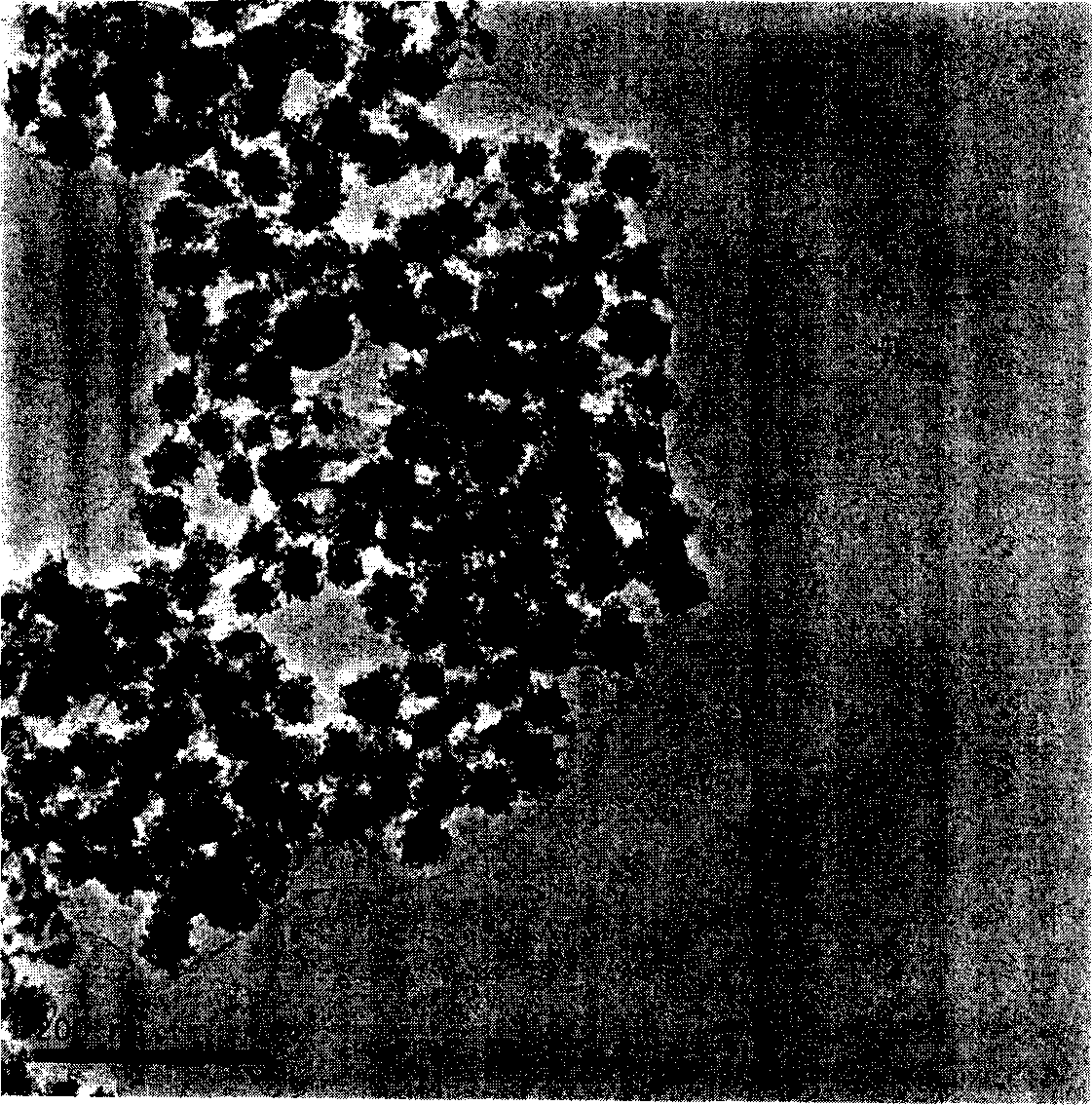

Image

Examples

Embodiment 1

[0022] Prepare nano-zinc powder, the preparation steps are:

[0023] Step 1, distilled water and dimethyl sulfoxide are mixed and dissolved according to the volume ratio of 1:80;

[0024] Step 2, using the solution obtained in step 1 as a solvent, adding zinc sulfate and dissolving it, making an electrolyte solution with a zinc ion concentration of 0.02 mol / liter, then adding surfactant sodium oleate to a concentration of 0.2 g / L Lift;

[0025] Step 3. Insert a titanium alloy ultrasonic probe into the solution obtained in step 2 as the cathode, and a zinc plate as the anode, apply pulsed direct current, and turn on the ultrasonic function at the same time, with an average current density of 0.2 amperes / cm 2 , the pulse frequency is 50 Hz, and the ultrasonic power is 10 kW;

[0026] Step 4. After applying the current at 6 o'clock, stop the electrolysis and filter the electrolyte, wash the collected zinc powder with absolute ethanol, and dry it with nitrogen at room temperatur...

Embodiment 2

[0028] Prepare nano-zinc powder, the preparation steps are:

[0029] Step 1, distilled water and dimethyl sulfoxide are mixed and dissolved according to the volume ratio of 1:50;

[0030] Step 2, using the solution obtained in step 1 as a solvent, adding zinc chloride and dissolving it to form an electrolyte solution with a zinc ion concentration of 0.1 mol / liter, and then adding surfactant polyethylene glycol to a concentration of 0.8 g / L;

[0031] Step 3. Insert a titanium alloy ultrasonic probe into the solution obtained in step 2 as the cathode, and a zinc plate as the anode, apply pulsed direct current, and turn on the ultrasonic function at the same time, with an average current density of 0.5 ampere / cm 2 , the pulse frequency is 50 Hz, and the ultrasonic power is 30 kW.

[0032] Step 4. After applying the current for 6 hours, stop the electrolysis and filter the electrolyte, wash the collected zinc powder with absolute ethanol, and dry it with nitrogen at room tempera...

Embodiment 3

[0034] Prepare nano-zinc powder, the preparation steps are:

[0035] Step 1, distilled water and dimethyl sulfoxide are mixed and dissolved according to the volume ratio of 1:20;

[0036] Step 2, take the solution obtained in step 1 as a solvent, add zinc nitrate and dissolve it thereinto, and make an electrolyte solution with a zinc ion concentration of 0.15 mol / liter, then add surfactant polyvinylpyrrolidone to a concentration of 5 grams / liter Lift;

[0037] Step 3. Insert a titanium alloy ultrasonic probe into the solution obtained in step 2 as the cathode, and a zinc plate as the anode, apply pulsed direct current, and turn on the ultrasonic function at the same time, with an average current density of 1 ampere / cm 2 , the pulse frequency is 50 Hz, and the ultrasonic power is 80 kW.

[0038] Step 4. After applying the current for 5 hours, stop the electrolysis and filter the electrolyte, wash the collected zinc powder with absolute ethanol, and dry it with nitrogen at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com