Patents

Literature

33results about How to "Reduce reaction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

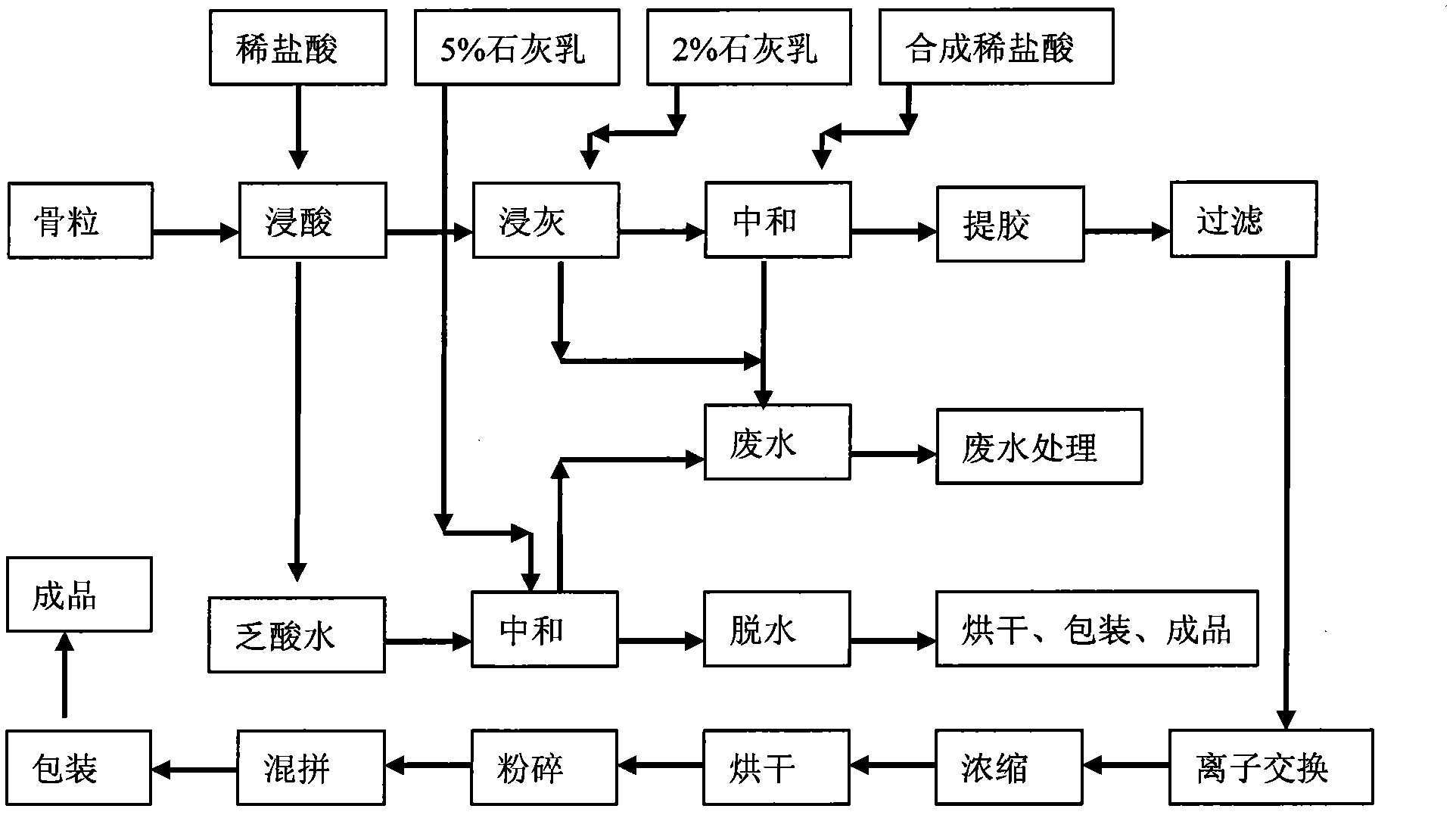

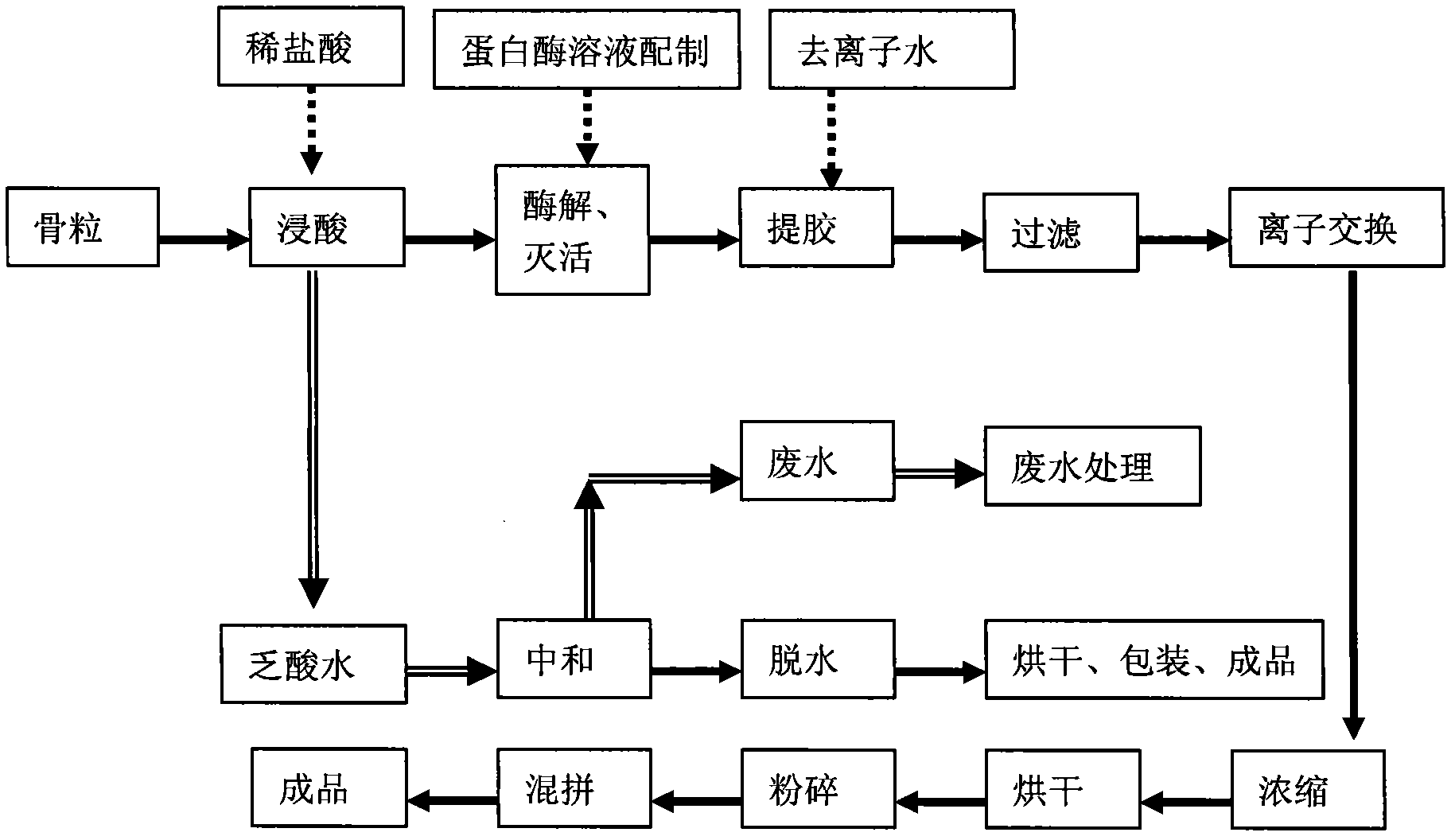

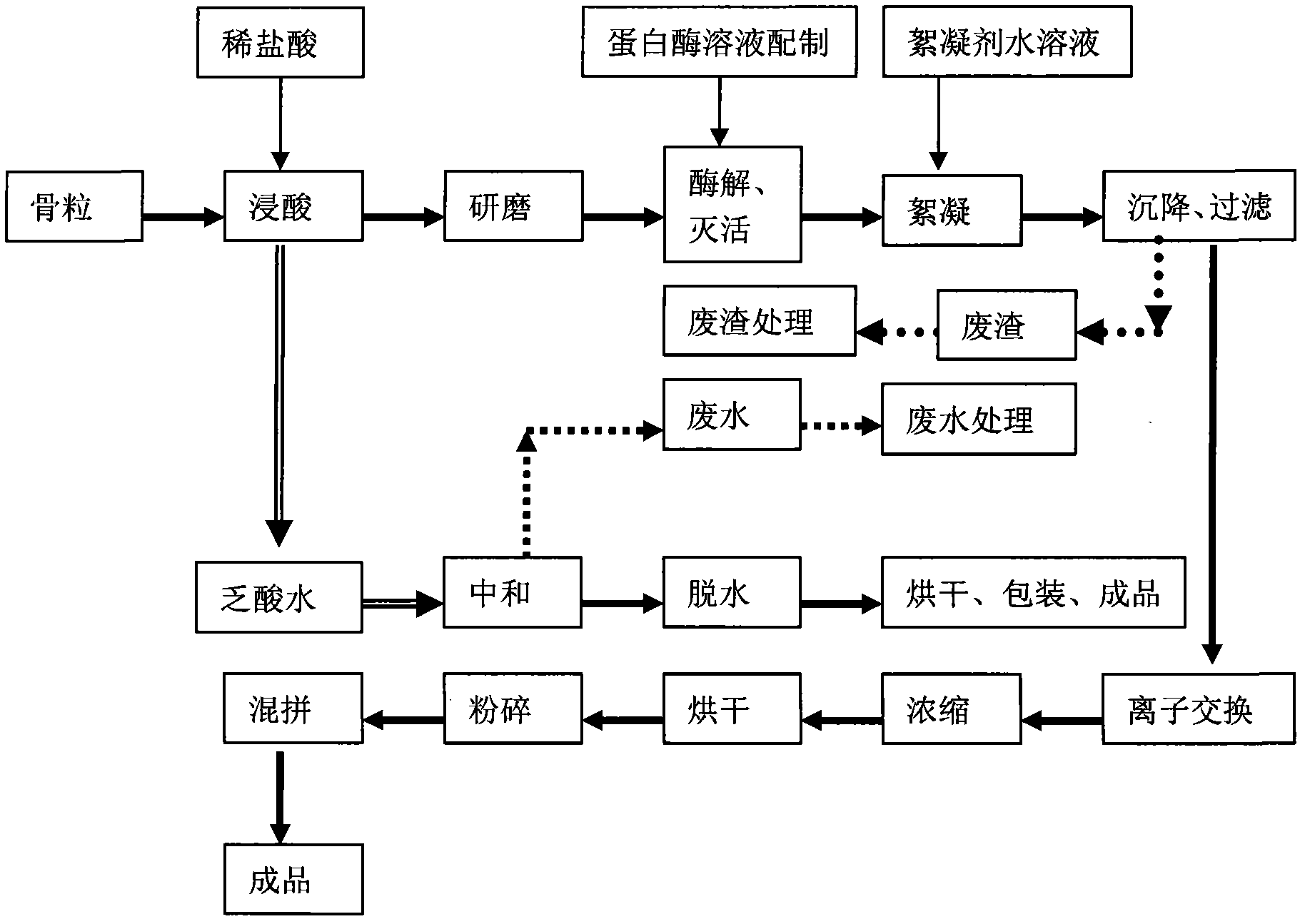

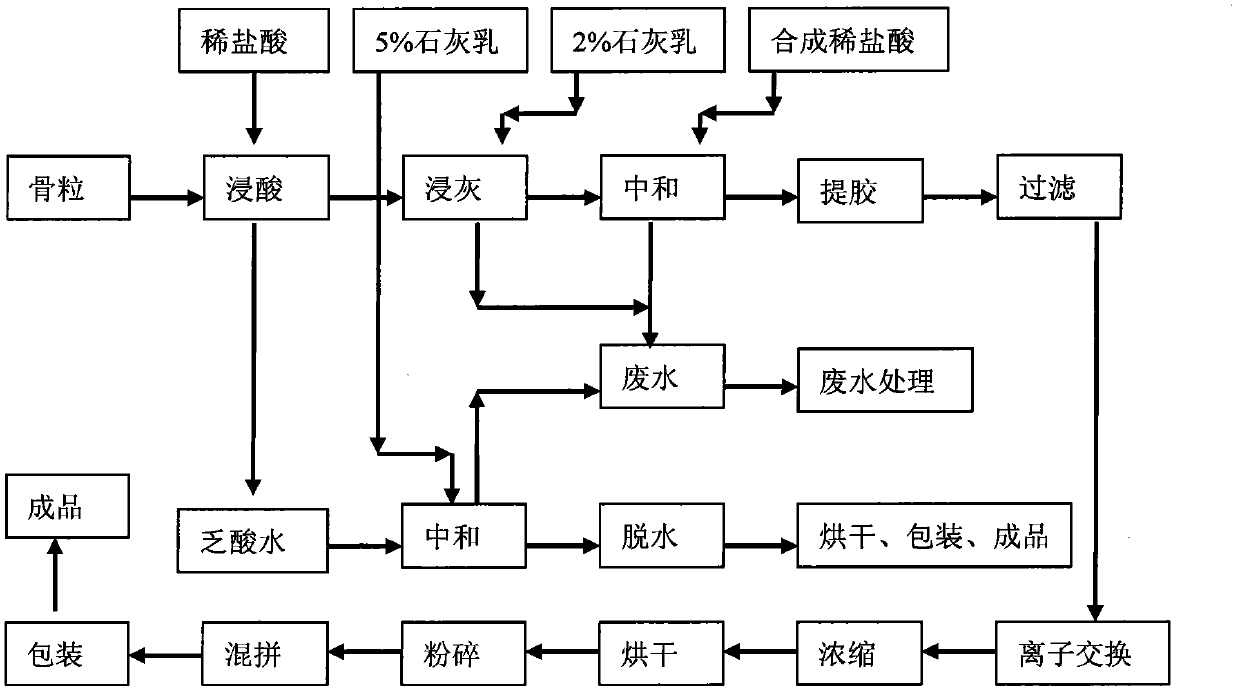

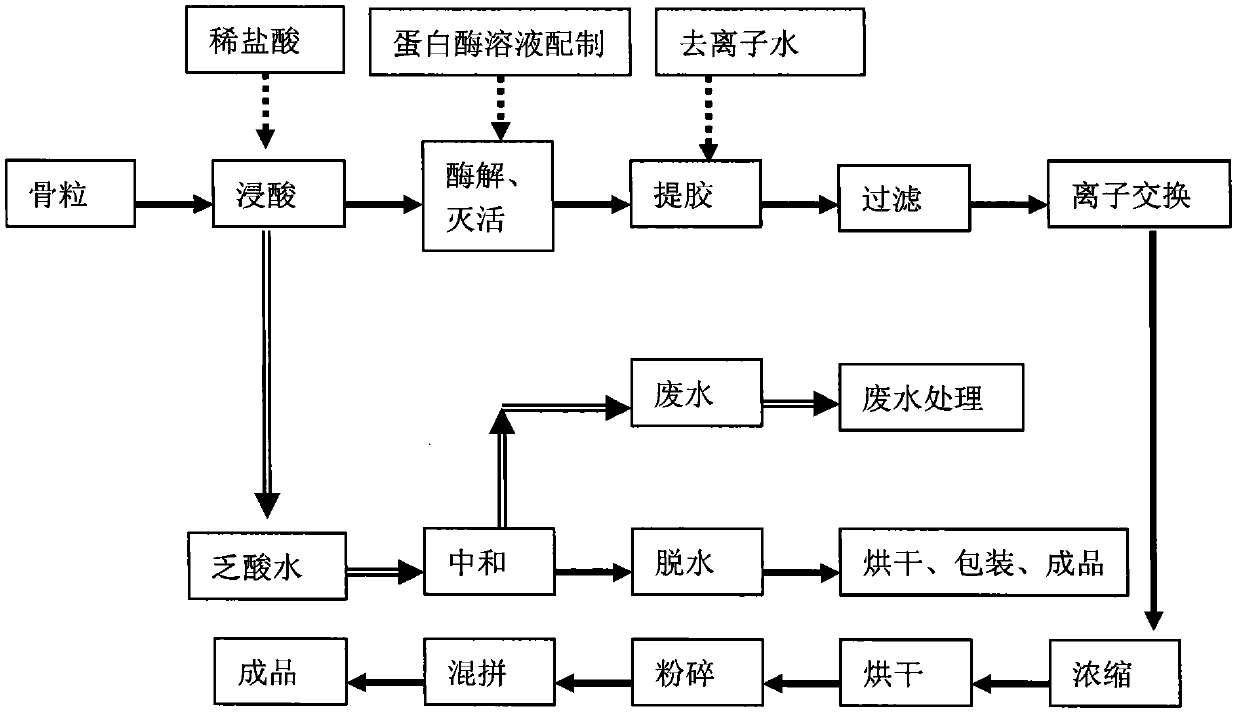

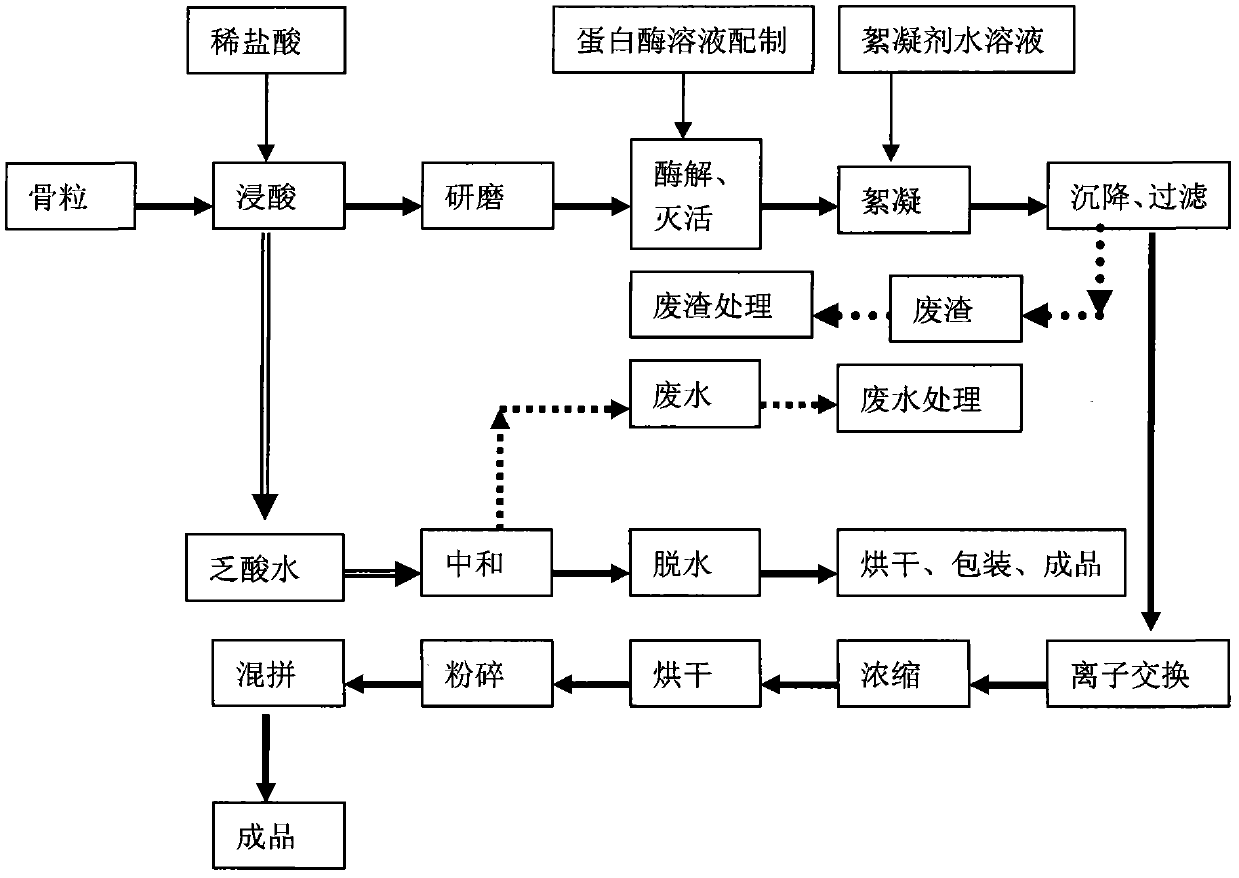

Enzyme method for preparing gelatin

ActiveCN102329843ALarge specific surface areaTake advantage ofGlue/gelatin preparationFermentationCalcium hydroxideProteinase activity

The invention relates to an enzyme method for preparing gelatin, which comprises the following steps of: pulverizing bone grains into bone meal, acidifying the bone meal by using phosphoric acid, and adding acid protease to hydrolyze; then, decoloring the solution by using hydrogen peroxide, and adjusting the pH value by using calcium hydroxide; and finally adding a flocculating agent. In the method provided by the invention, phosphoric acid is adopted for acidification, because a great amount of soluble calcium salts is formed, the enzymolysis reaction is mild. The defect that the enzymolysis end point of the finely ground collagen (ossein) enzymolysis method is difficult to control is overcome by controlling the end point of the enzymolysis reaction, so that the enzymolysis method for preparing gelatin is more practical.

Owner:安徽丰原集团有限公司

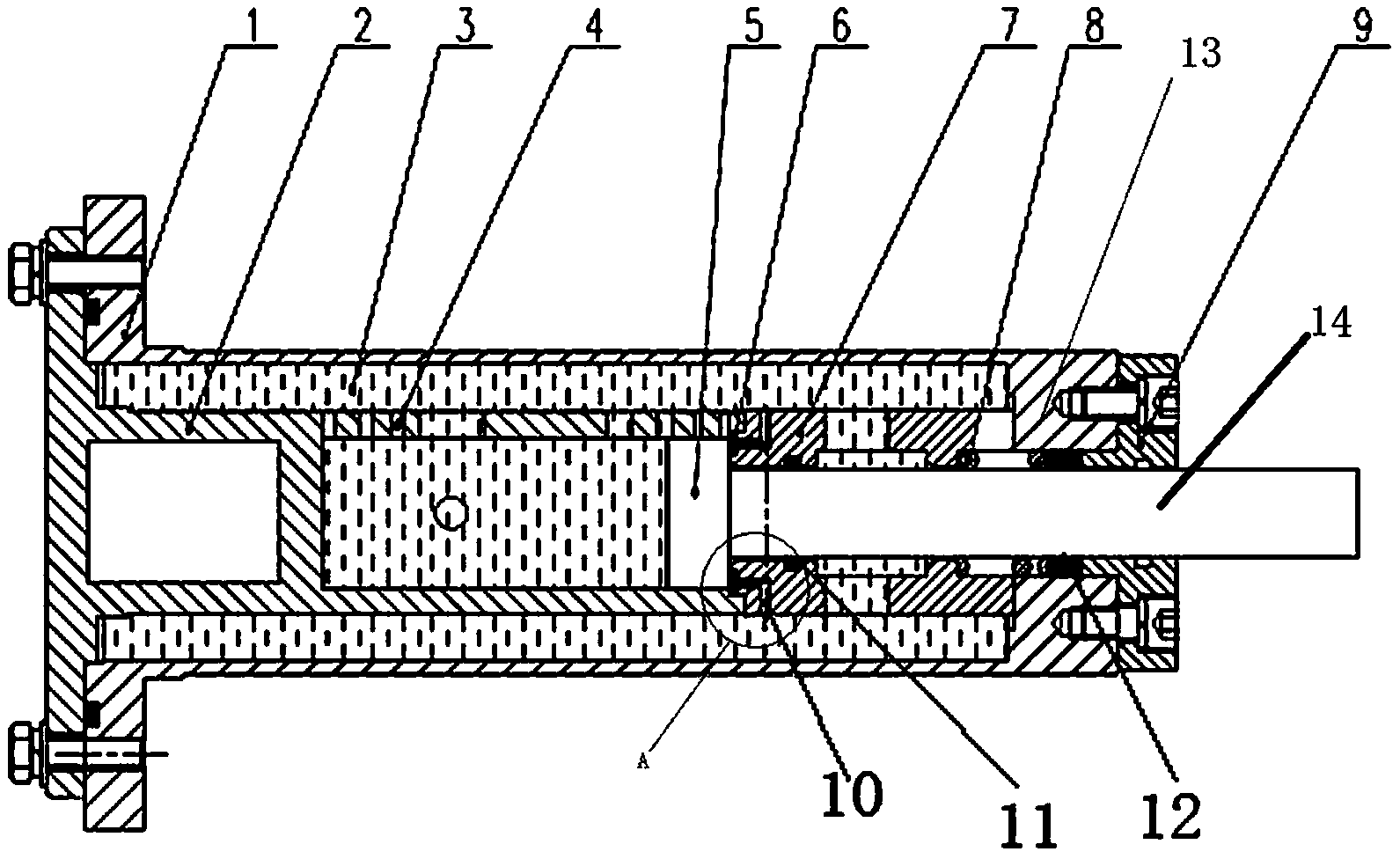

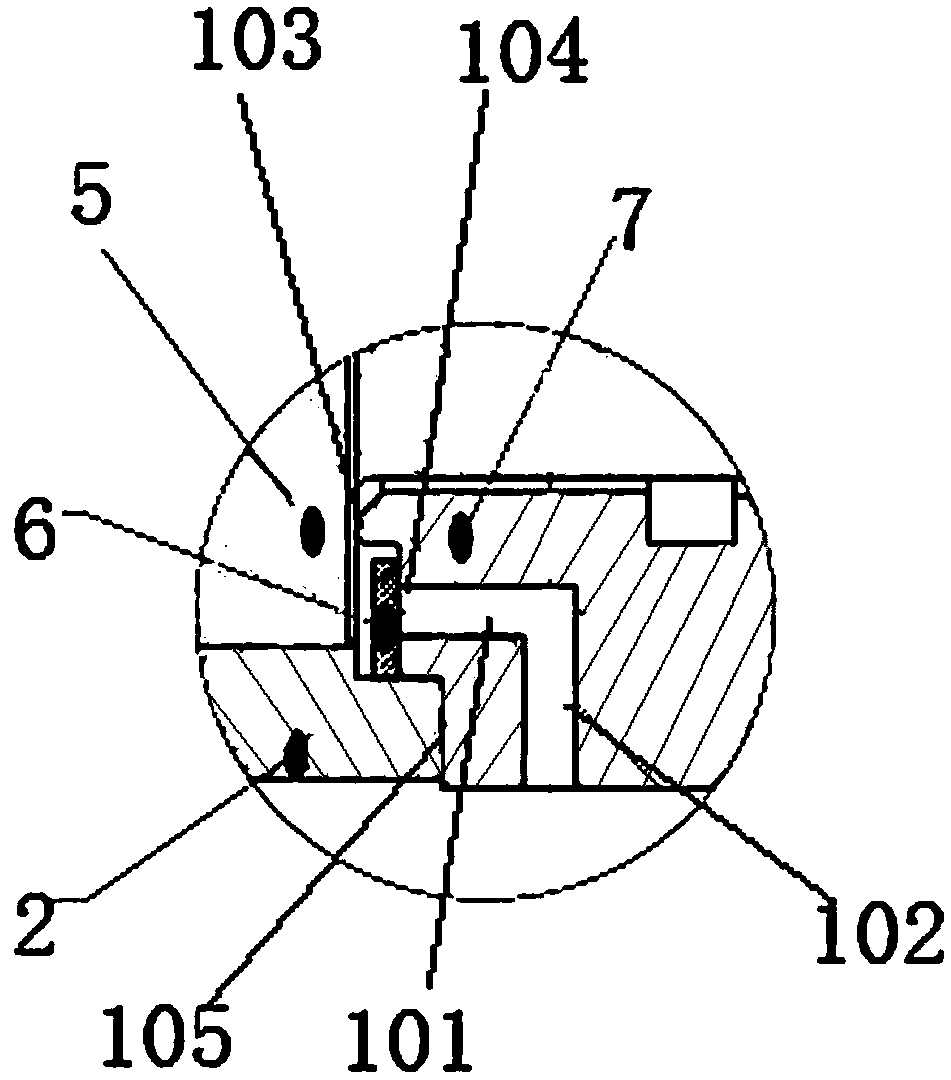

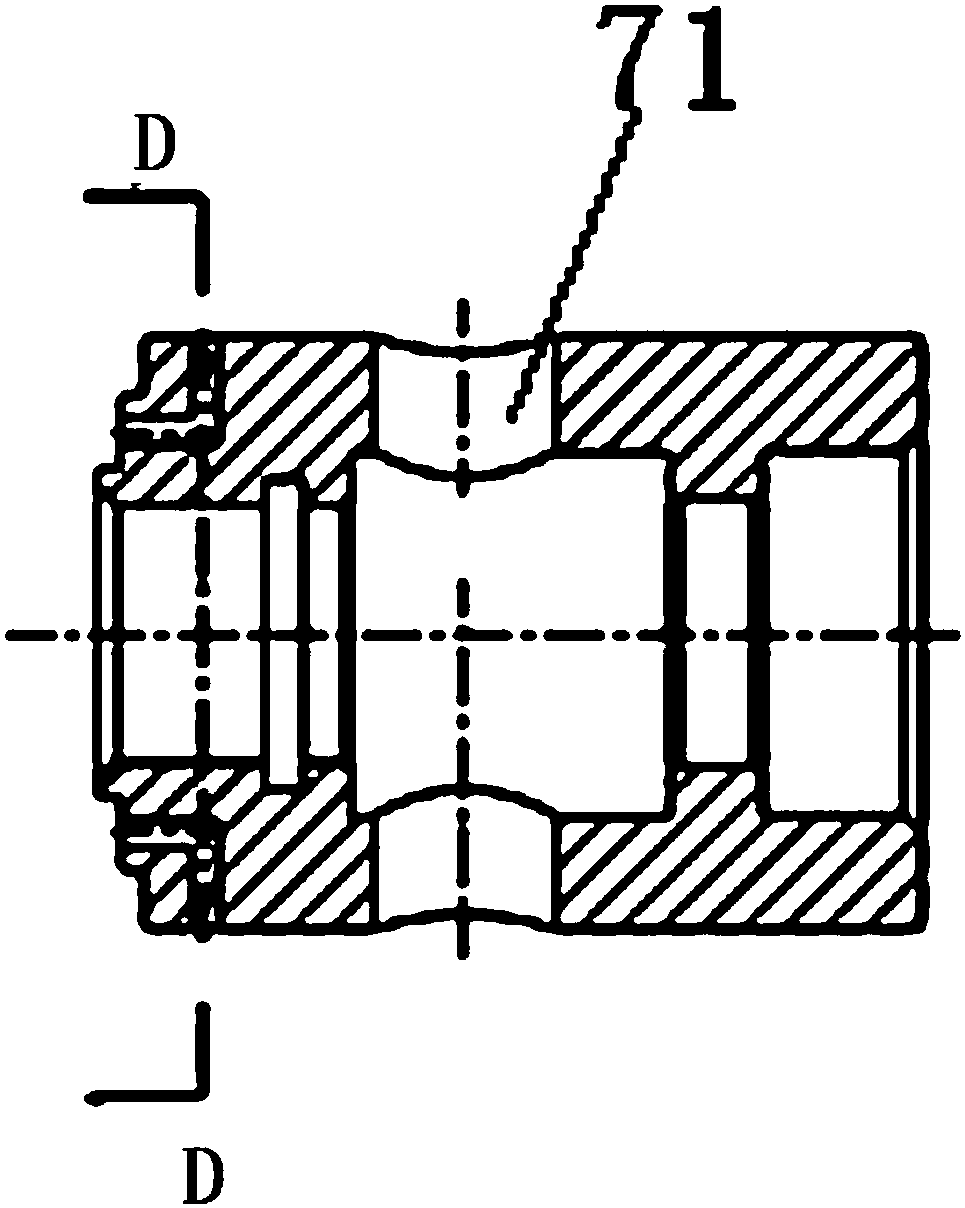

Spring operating mechanism buffer for circuit breaker

ActiveCN104134557AClosing speed is fastInfluence of opening parametersContact vibration/shock dampingReciprocating motionEngineering

The invention discloses a spring operating mechanism buffer for a circuit breaker. The spring operating mechanism buffer comprises an inner cylinder body and an outer cylinder body which are in sleeved mounting in a clearance manner, wherein a clearance cavity is formed by an outer circumference face of the inner cylinder body and an inner circumference face of the outer cylinder body; a piston for driving hydraulic oil to flow between an inner cavity of the inner cylinder body and the clearance cavity is assembled in the inner cylinder body in a reciprocating motion manner; a through-flow hole for communicating the inner cavity of the inner cylinder body with the clearance cavity and capable of satisfying switch-off performance of the circuit breaker is formed in the inner cylinder body; an acceleration channel is arranged in the outer cylinder body; one end of the acceleration channel is communicated with the inner cavity of the inner cylinder body; the other end of the acceleration channel is communicated with the clearance cavity; and a check valve structure for controlling breakover of the acceleration channel in a switch-on process of the circuit breaker and cutoff of the acceleration channel in a switch-off process of the circuit breaker is arranged on the acceleration channel. The buffer can effectively solve the problem of low switch-on speed in a test process of the circuit breaker, does not influence technical parameters in the switch-off process of the circuit breaker, and improves reliability and stability of circuit breaker products.

Owner:STATE GRID CORP OF CHINA +2

Method for preparing diphenylmethane dicarbamic acid ester in double solvent system

InactiveCN101440048AReduce reaction resistanceHigh catalytic activityCarbamic acid derivatives preparationOrganic compound preparationOrganic acidCarbamate

The invention relates to a method for synthesizing diphenylmethane diurethane through catalysis of liquid acid in a composite solvent system, in particular for synthesizing 4,4,-diphenylmethane diurethane. In the composite component solvent system, a phenyl carbamate reagent and a methylenation reagent are catalyzed and condensed through liquid organic acid; a composite component solvent can well promote catalytic activity of the liquid acid; and in the process of synthesizing the diphenylmethane diurethane by one-step reaction, the conversion rate of phenyl carbamate as a raw material reaches 97.46 percent, the yield of diphenylmethane diurethane is 86.93 percent, the selectivity of 4,4,- diphenylmethane diurethane in a product can reach 91.56 percent, and only a few byproducts are generated. After the reaction is completed, an MDC product can be separated through filtering and washing; the solvent can be recycled; after recycling, the yield of the MDC can still reach over 80 percent; and the method has good effect and does not cause the waste of the raw materials and the solvent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

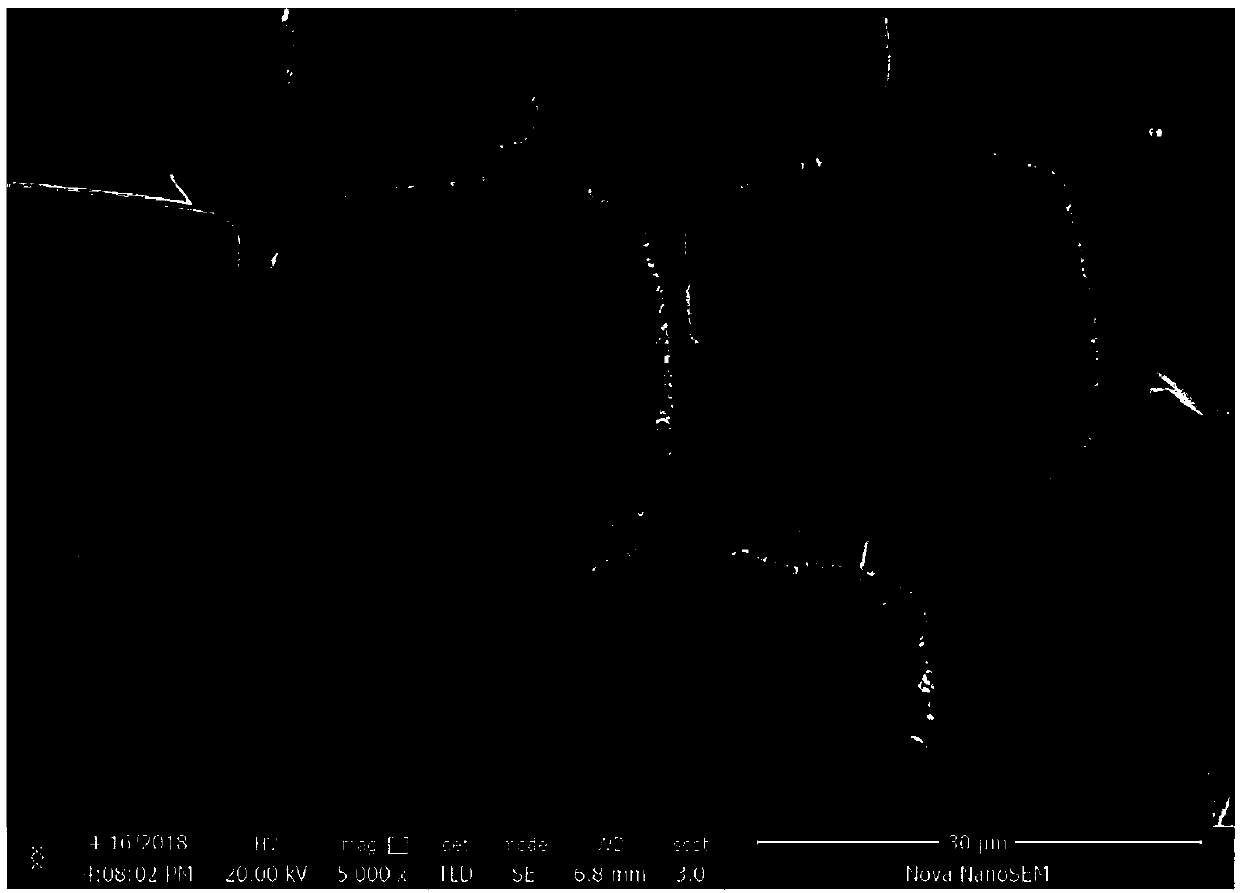

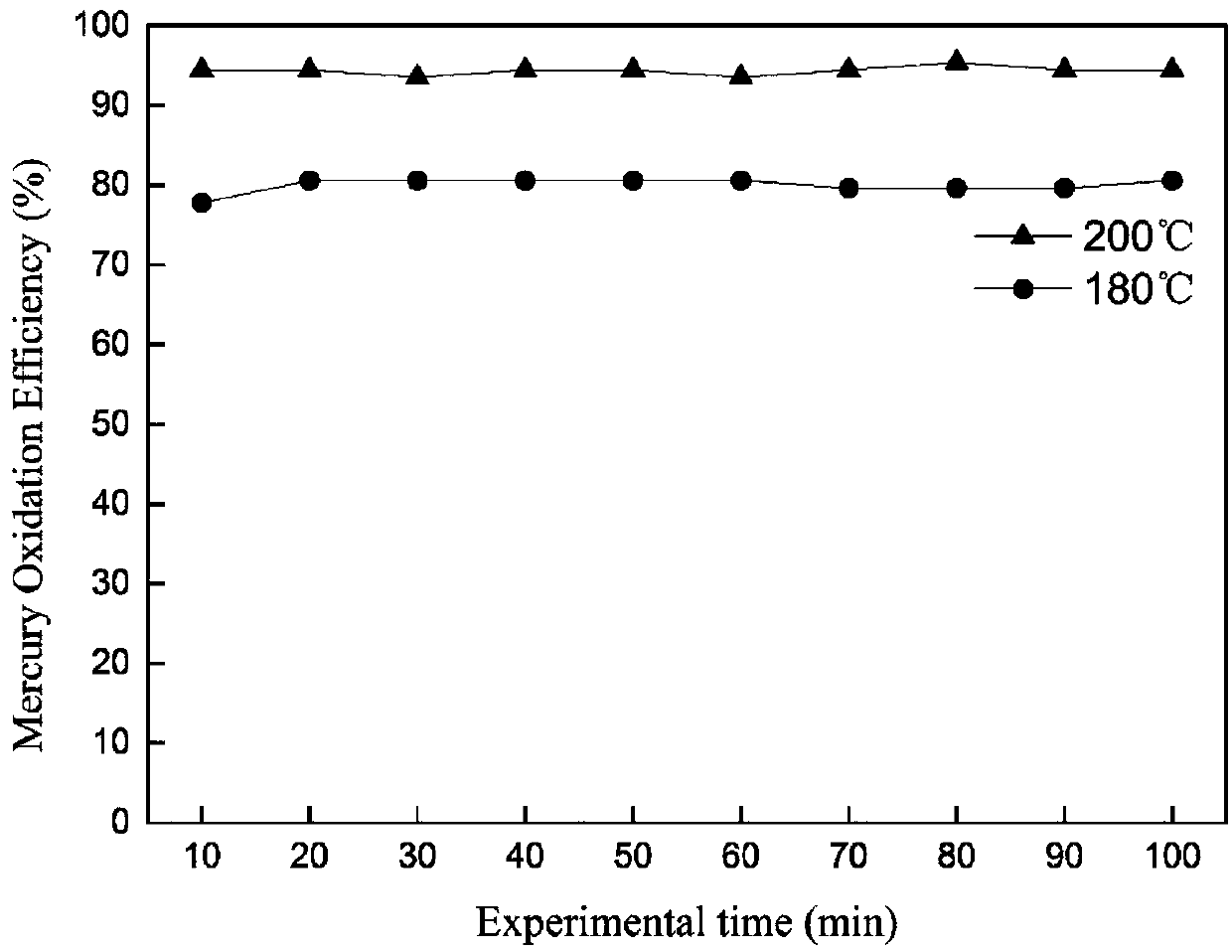

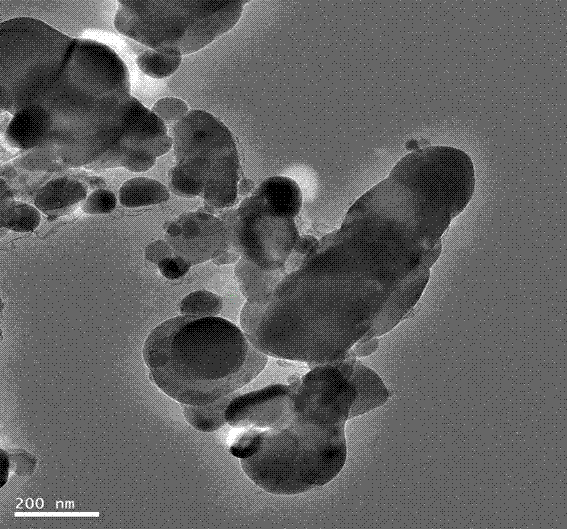

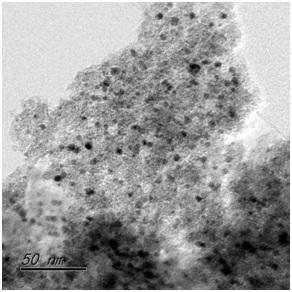

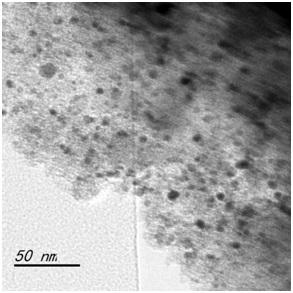

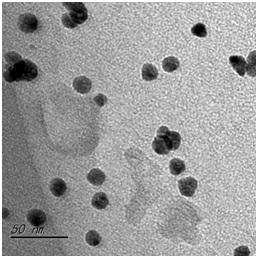

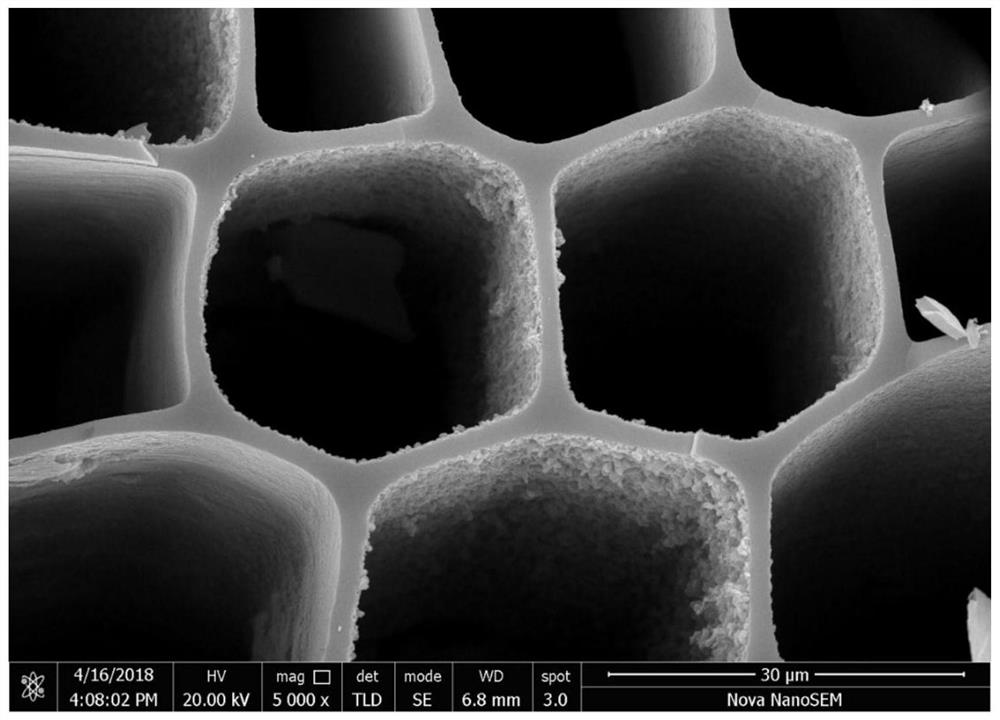

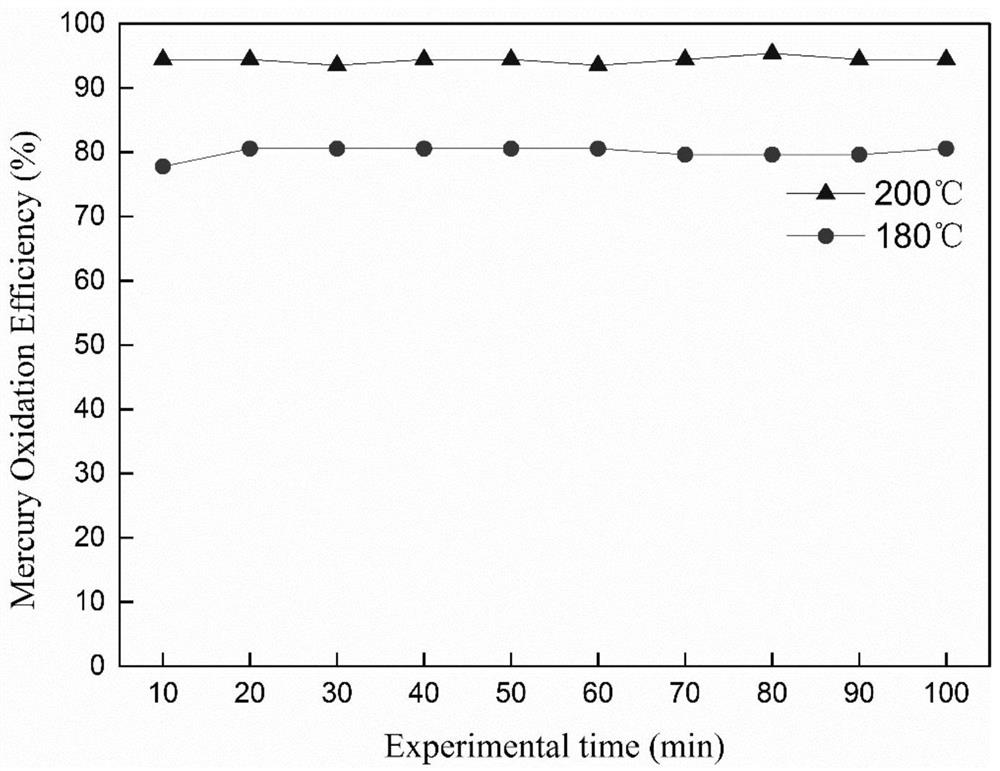

Preparation method for cobalt-modified porous charcoal catalyst for demercuration

ActiveCN109529845AWide variety of sourcesWide range of sources, cheap and easy to getGas treatmentDispersed particle separationBULK ACTIVE INGREDIENTCobalt

The invention discloses a preparation method for a cobalt-modified porous charcoal catalyst for demercuration and belongs to the technical field of control on mercury discharge of coal-fired flue gas.The preparation method comprises the following steps: taking fir as a charcoal carrier and taking Co3O4 as an active ingredient; adopting a sol-gel method for paving a crystal seed layer of crystal;performing hydro-thermal treatment for realizing growth of Co3O4 nanocrystal; performing carbonizing treatment, thereby acquiring a supported catalyst with high-dispersion active ingredients. According to the invention, source of raw materials is extensive, process is simple and controllable, operation conditions are mild and the demercuration efficiency of the acquired Co-modified porous charcoalcatalyst under different temperatures is above 80%.

Owner:DALIAN UNIV OF TECH

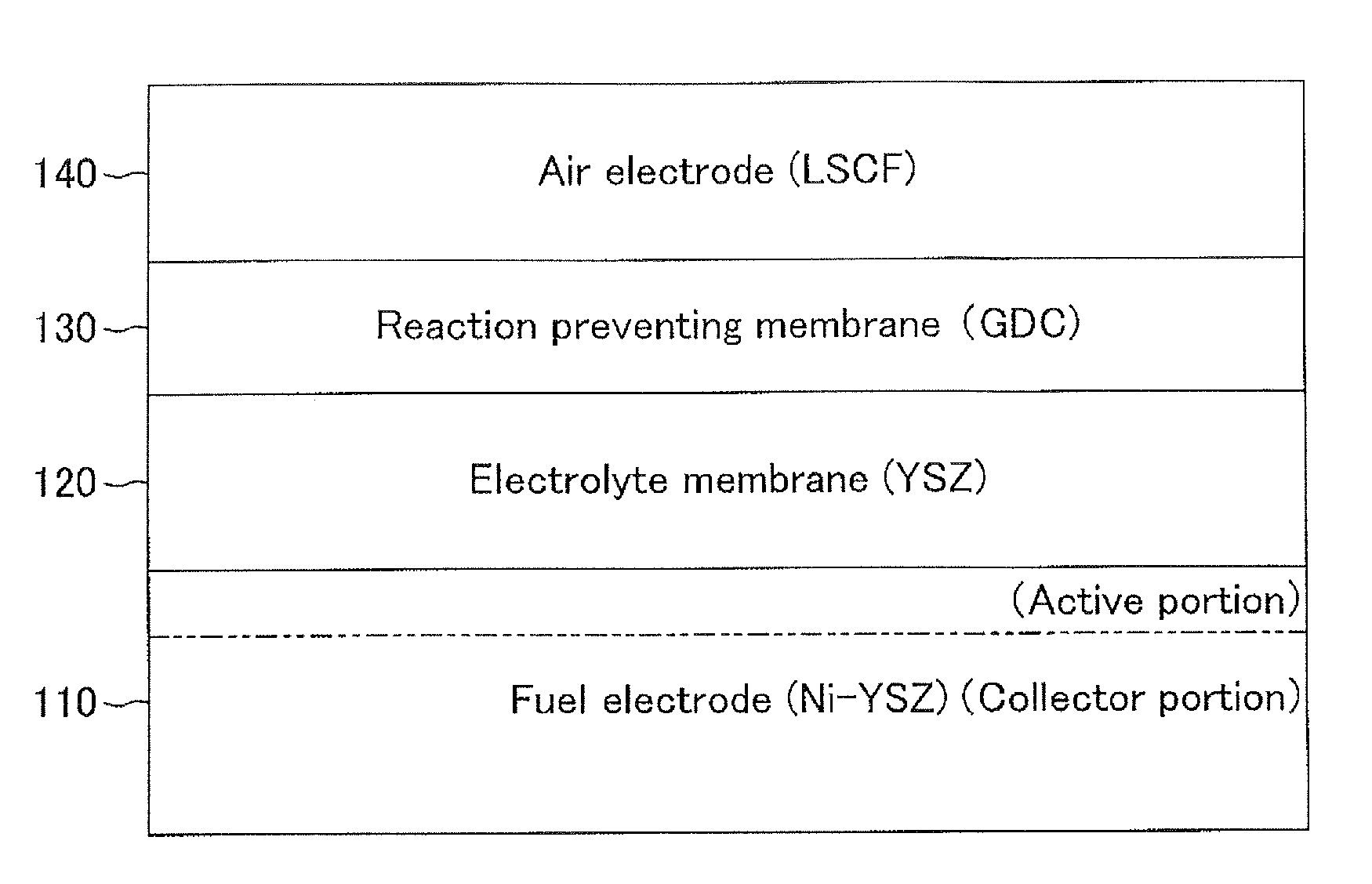

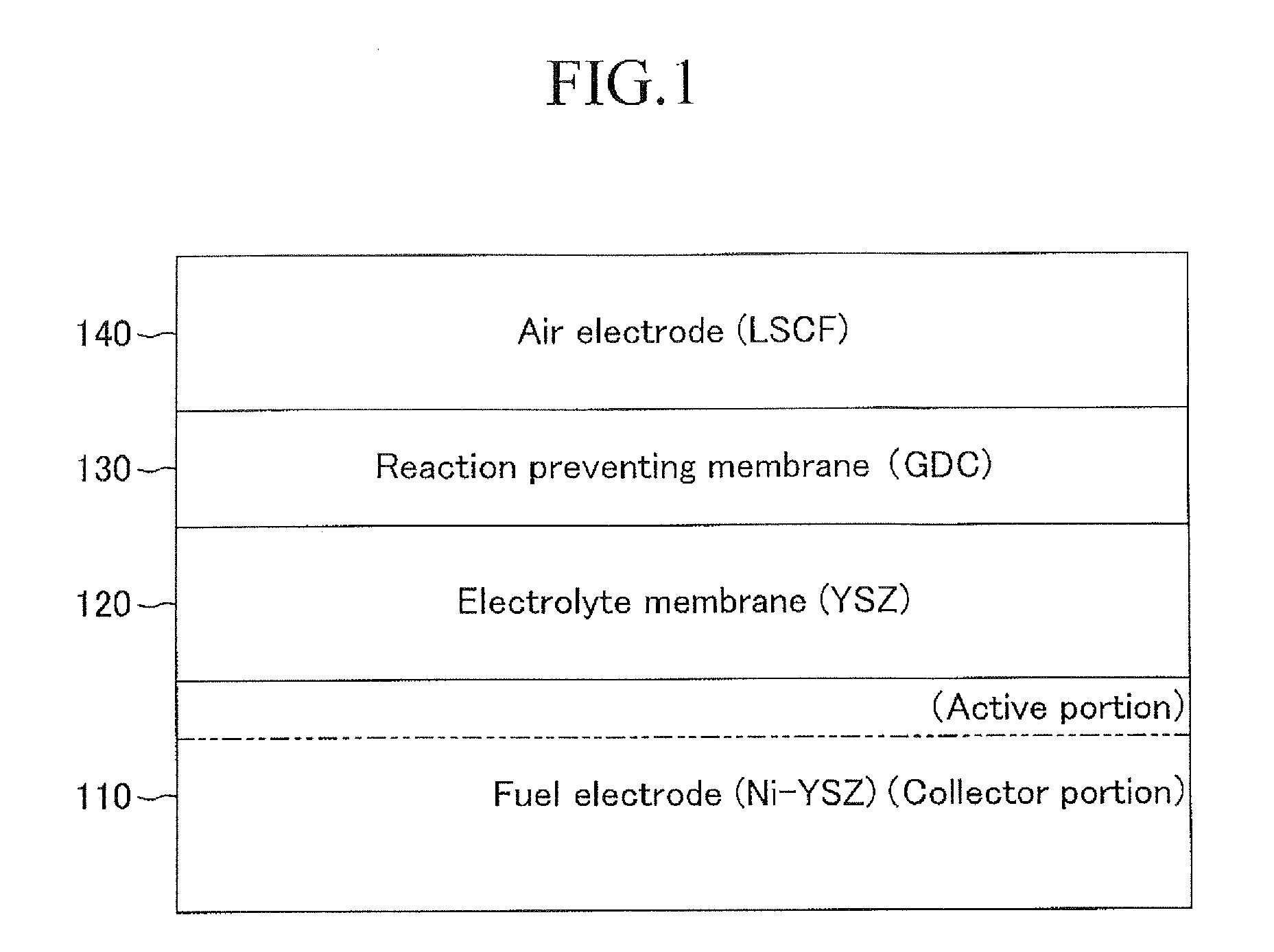

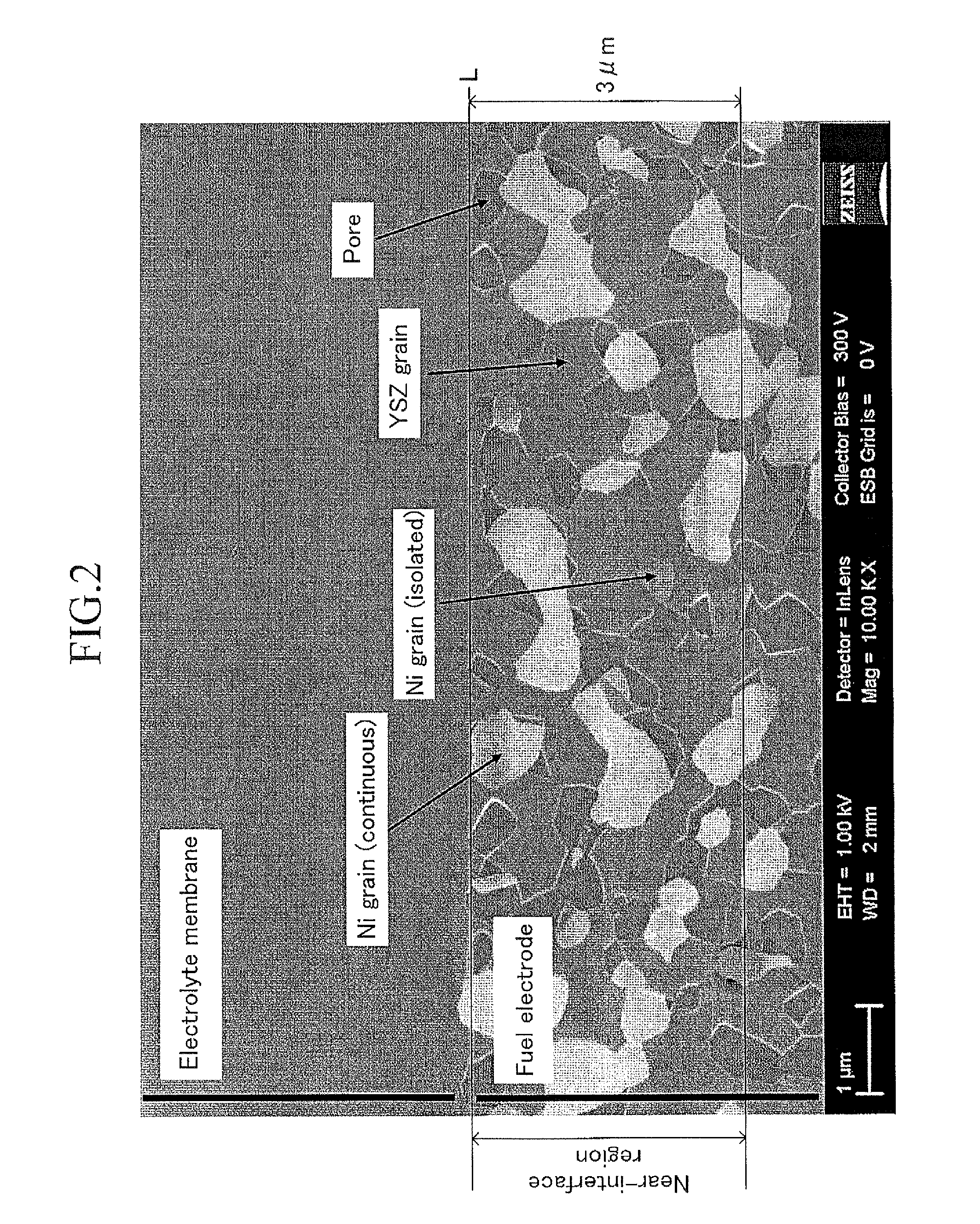

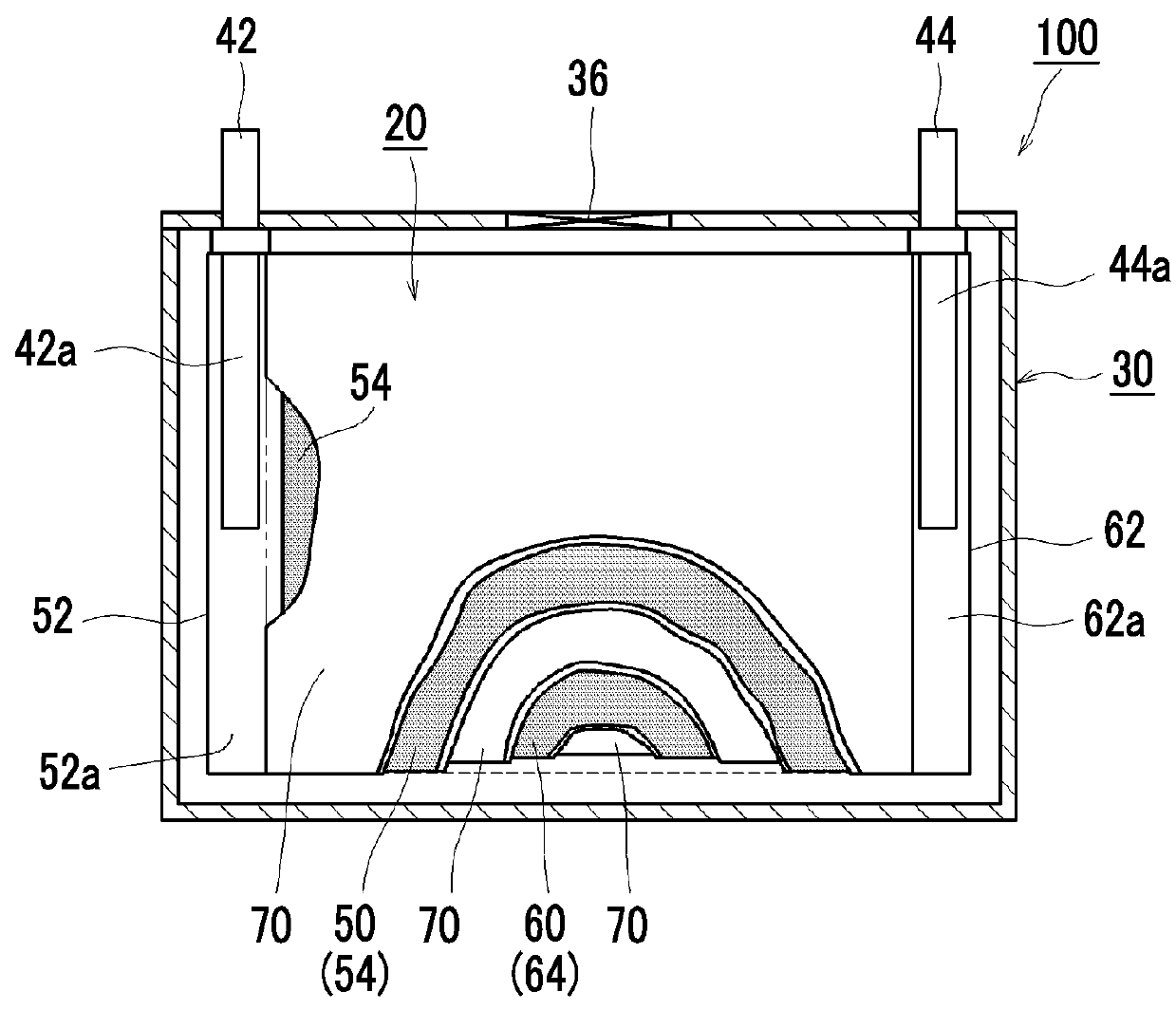

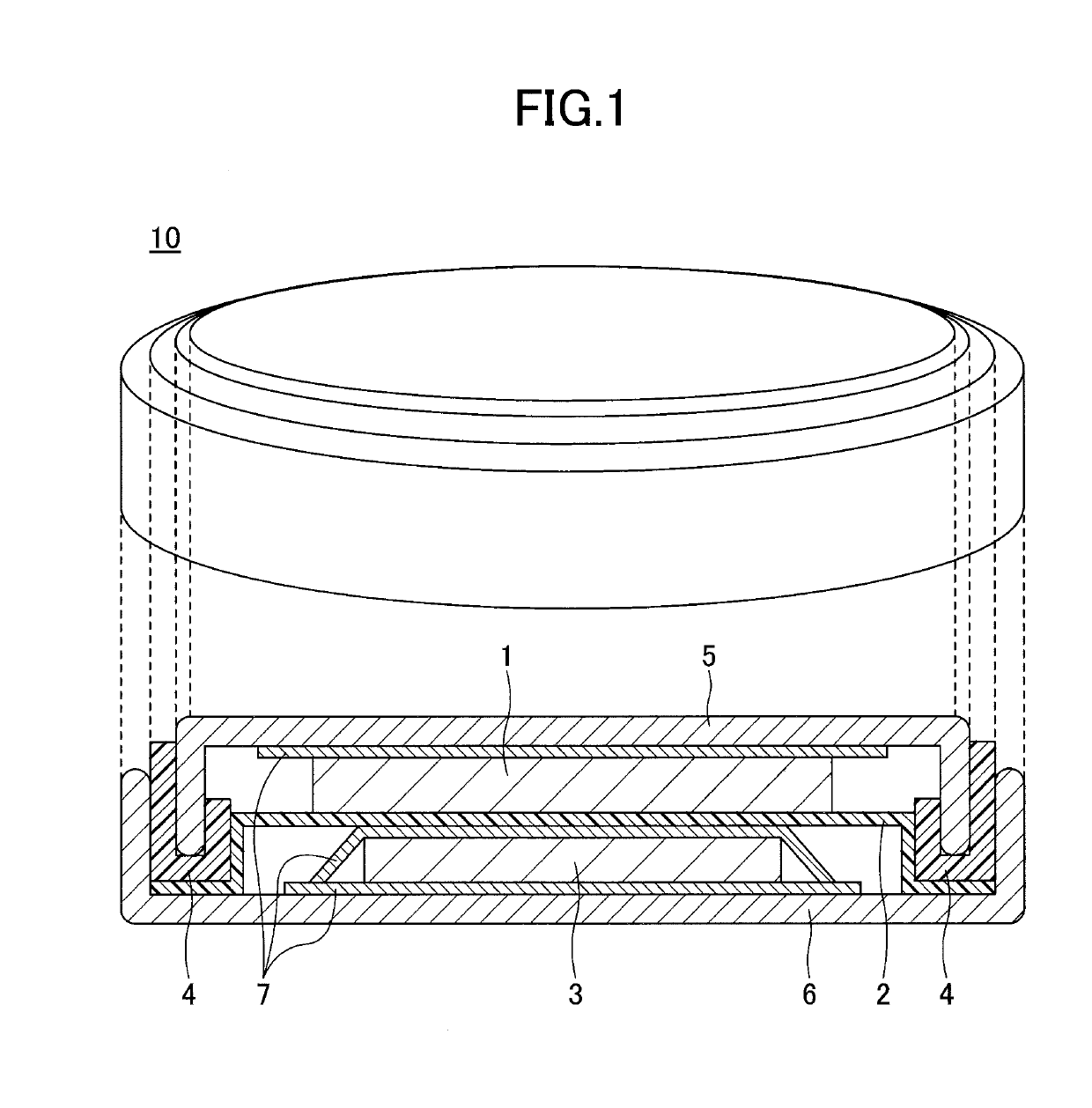

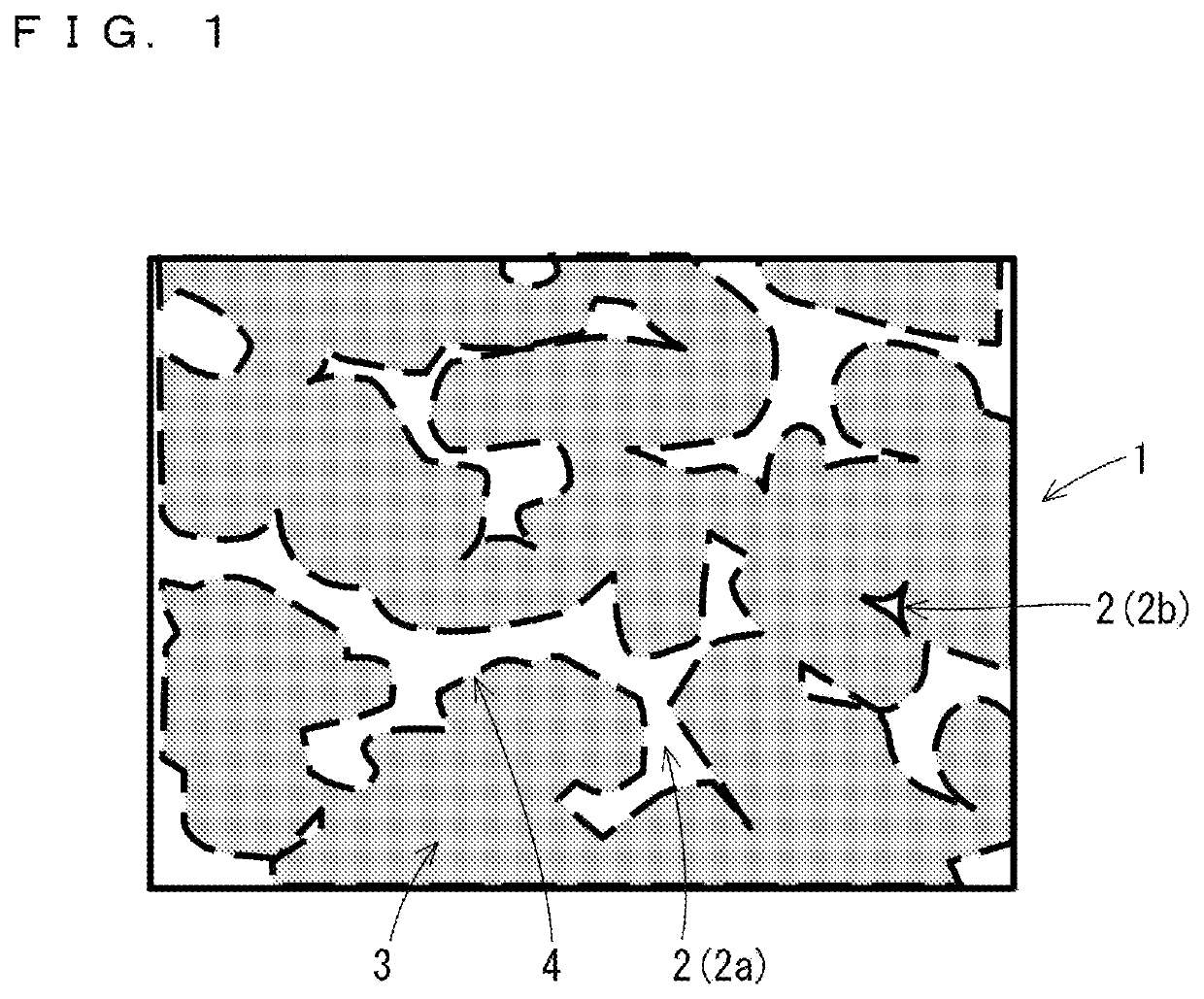

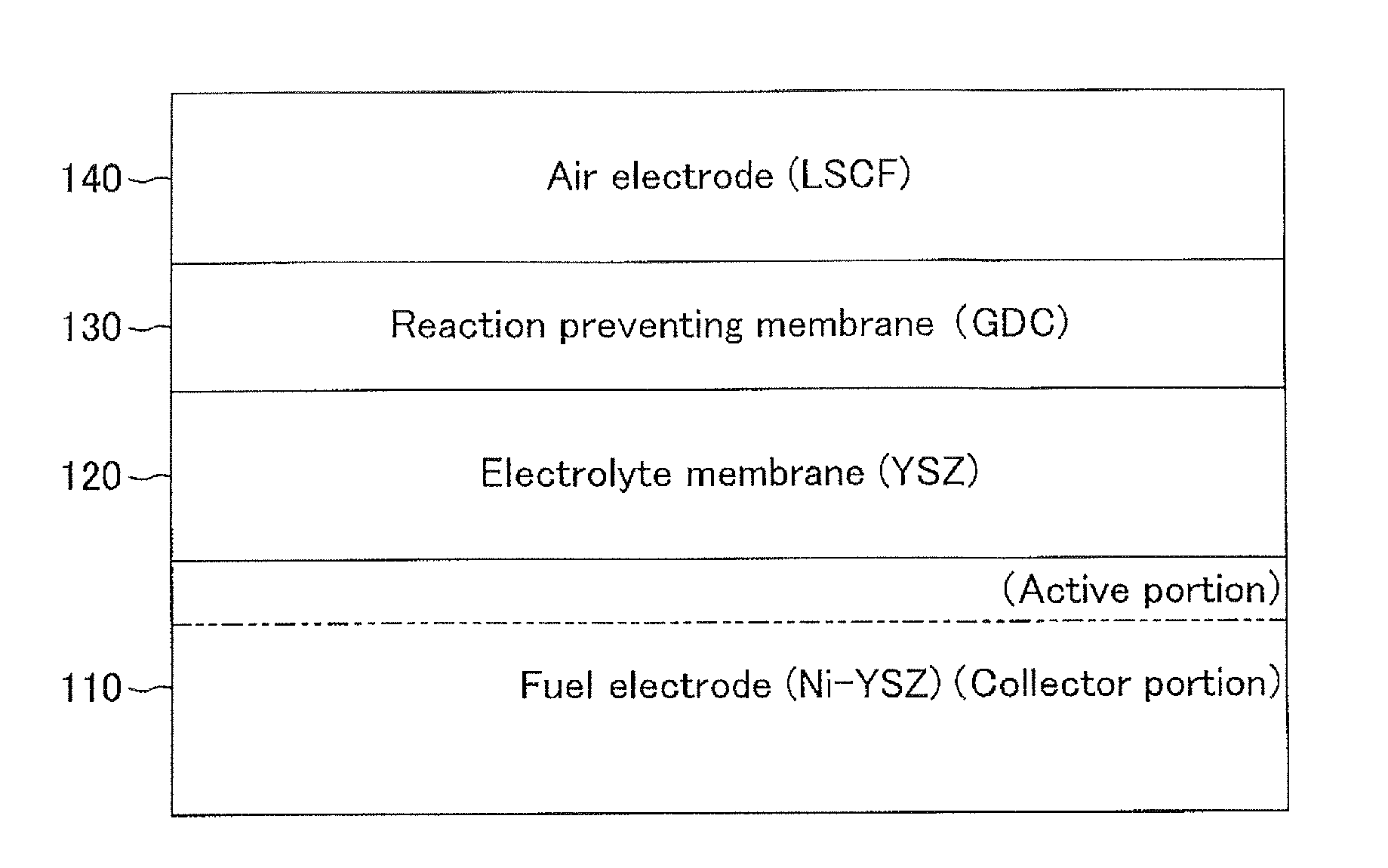

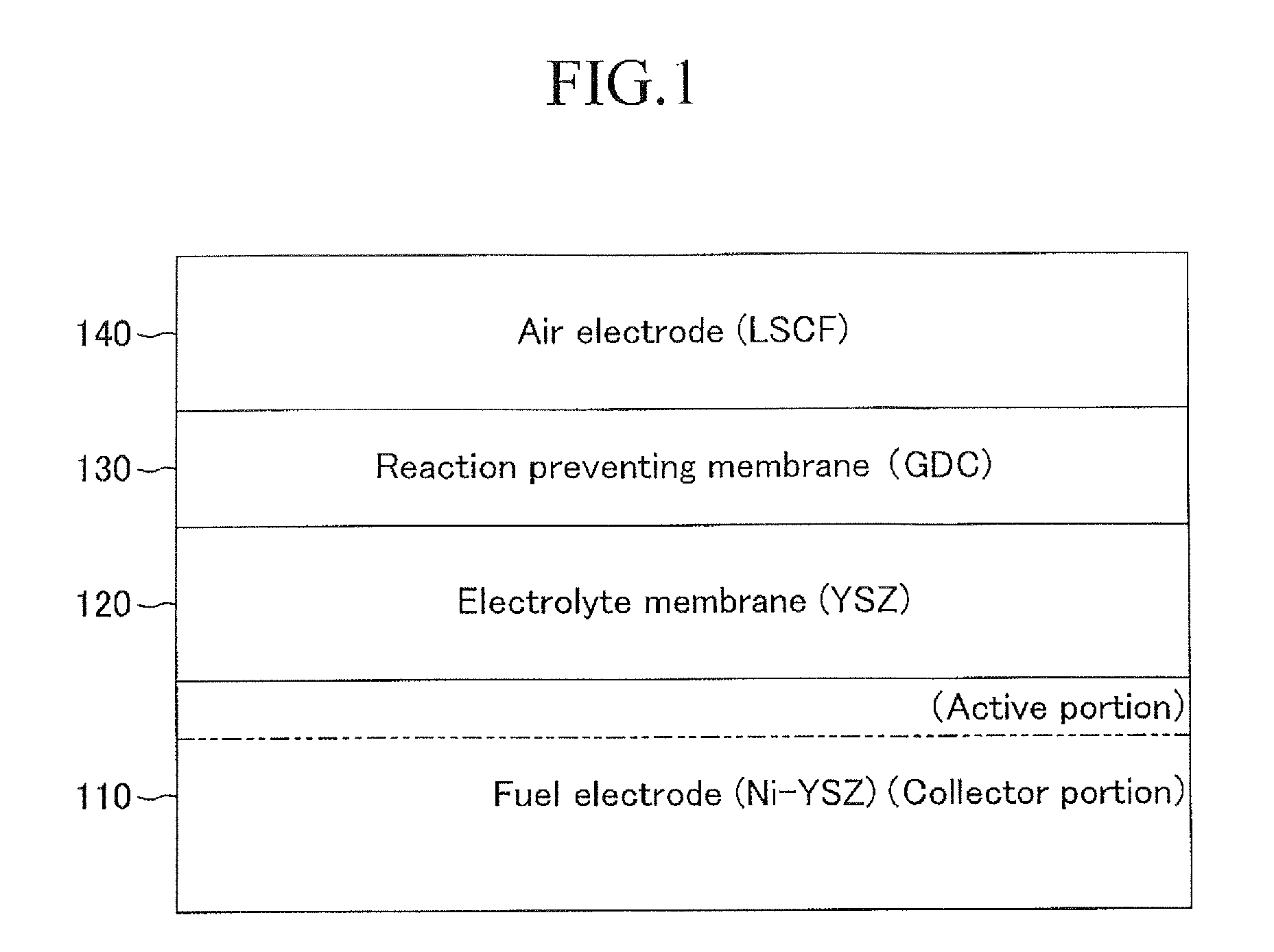

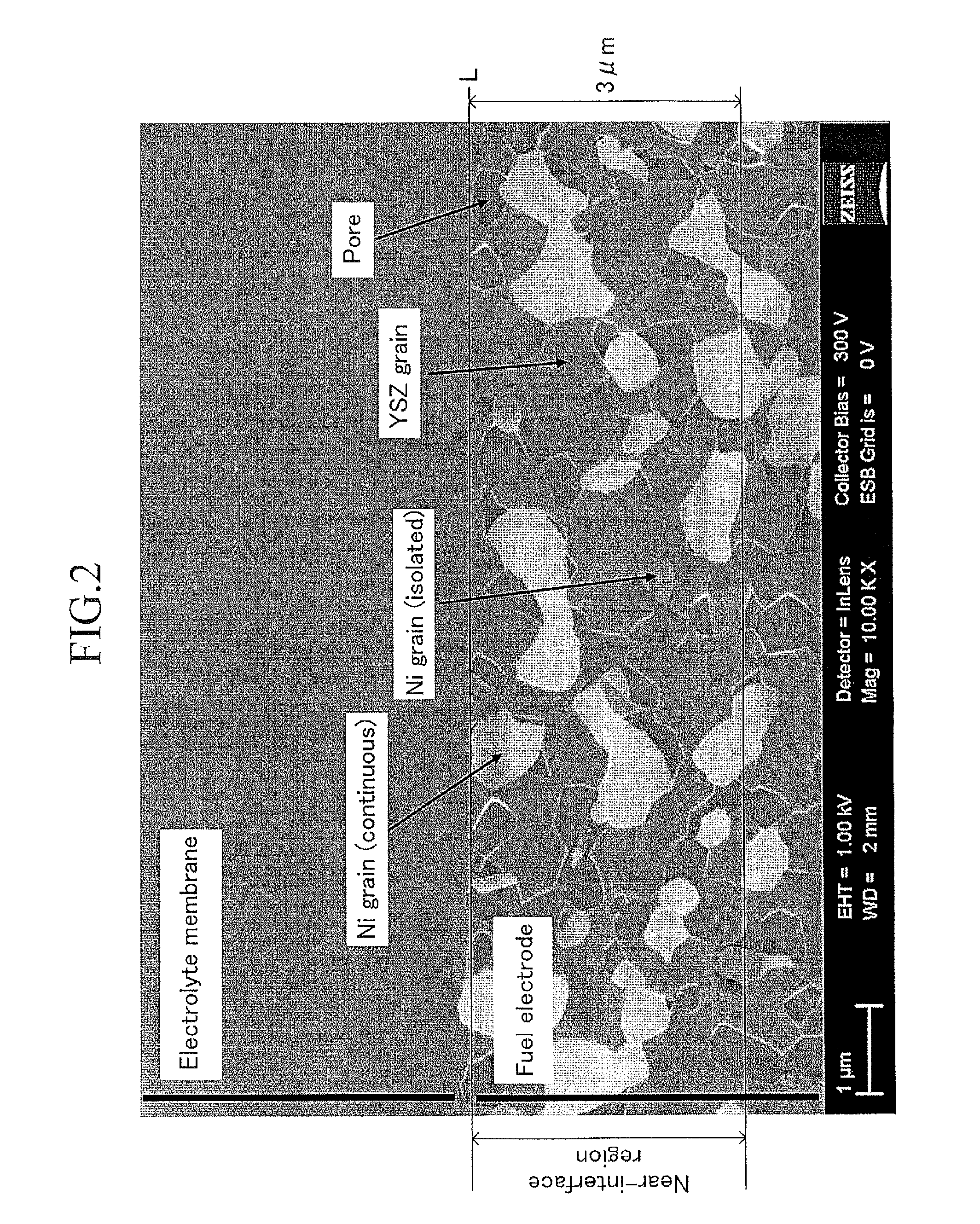

Solid oxide fuel cell

ActiveUS20120237849A1Reduced responseReduce resistanceCell electrodesFinal product manufactureElectrical resistance and conductanceFuel cells

The present invention provides a solid oxide fuel cell (SOFC) including a “porous fuel electrode which allows reaction of a fuel gas to proceed and which is formed of Ni and YSZ”; a “porous air electrode which allows reaction of an oxygen-containing gas to proceed”; and a “dense solid electrolyte membrane which is provided between the fuel electrode and the air electrode and which has an interface with the fuel electrode.” In the fuel electrode, Ni grains present in a region located within 3 μm from the interface (i.e., a “near-interface region”) have a mean size of 0.28 to 0.80 μm; YSZ grains present in the “near-interface region” have a mean size of 0.28 to 0.80 μm; and pores present in the “near-interface region” have a mean size of 0.10 to 0.87 μm. Thus, the fuel electrode of the SOFC exhibits low reaction resistance.

Owner:NGK INSULATORS LTD

Method for promoting quality of oil pyrolyzed from sludge

ActiveCN105295981AReduce reaction resistanceImprove distributionSludge treatment by pyrolysisByproduct vaporizationWater basedResource utilization

The invention provides a method for promoting the quality of oil pyrolyzed from sludge. The method provided by the invention comprises the following steps: mixing sludge, waste biomass and a catalyst according to a weight ratio of 1: (1.0 to 1.5): (0.01 to 0.05); putting the mixture in a fixed bed reactor under a nitrogen atmosphere, segmentally pyrolyzing according to a certain temperature rise program, gradually raising the temperature to 550 DEG C, and condensing generated gas in a condensation device, wherein the yield and the quality of the obtained pyrolyzed oil, which are higher than those of oil pyrolyzed from pure sludge under the same conditions, are respectively: the oil productivity (no water base) is 35% to 45%, the lower calorific value is 30 to 35MJ / kg and the velocity is 15 to 18mm<2> / g. According to the method provided by the invention, the waste biomass and the sludge are co-pyrolyzed, the advantage that the waste biomass and the sludge are pyrolyzed separately is utilized sufficiently to supplement each other, the quality of the oil pyrolyzed from the sludge is promoted, the environmental pollution problem of the two wastes is solved, and clean and high-efficient resource utilization of the two wastes is realized.

Owner:HUAQIAO UNIVERSITY

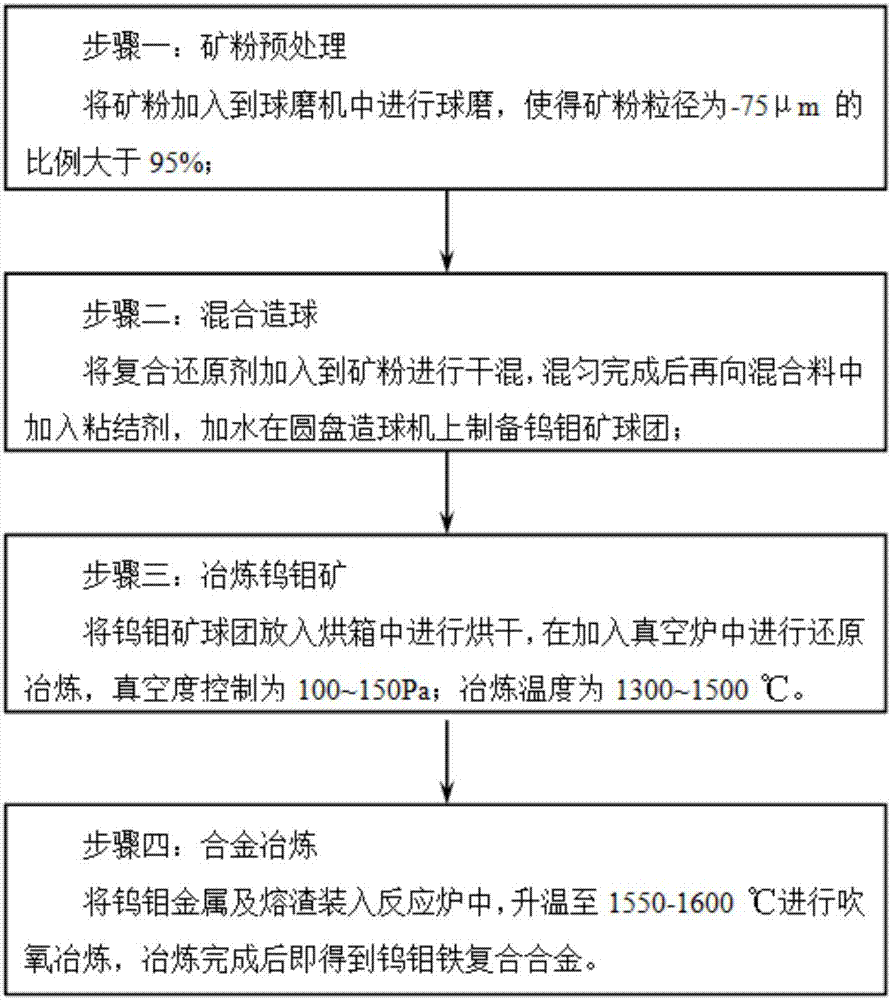

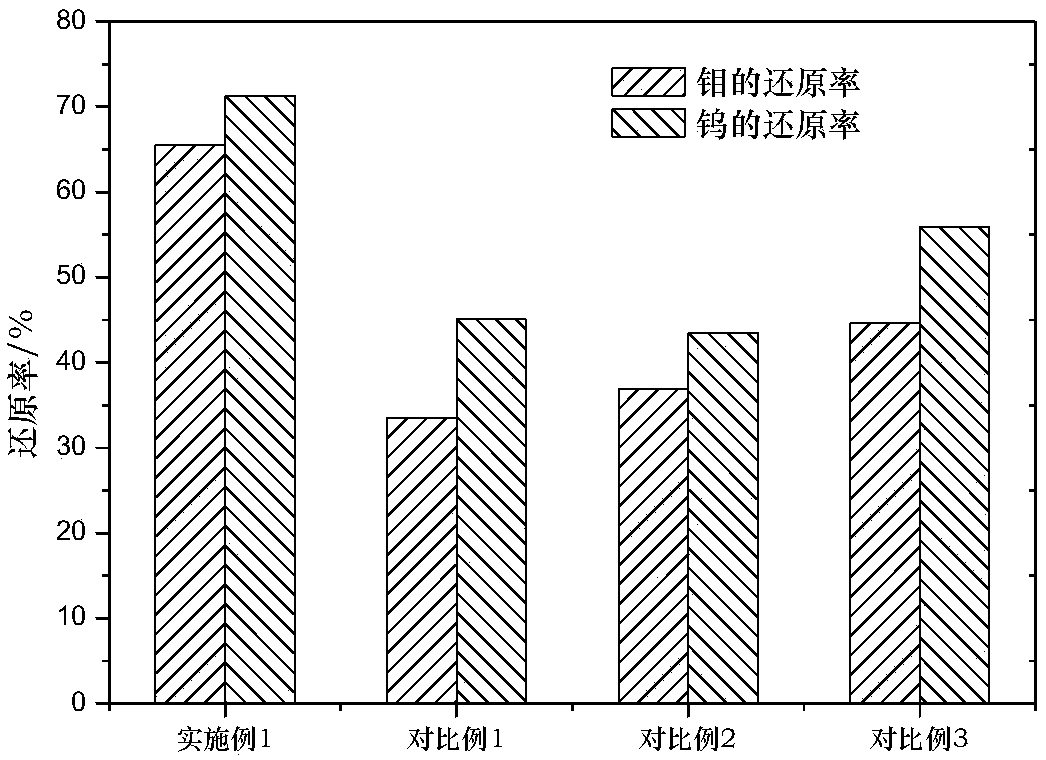

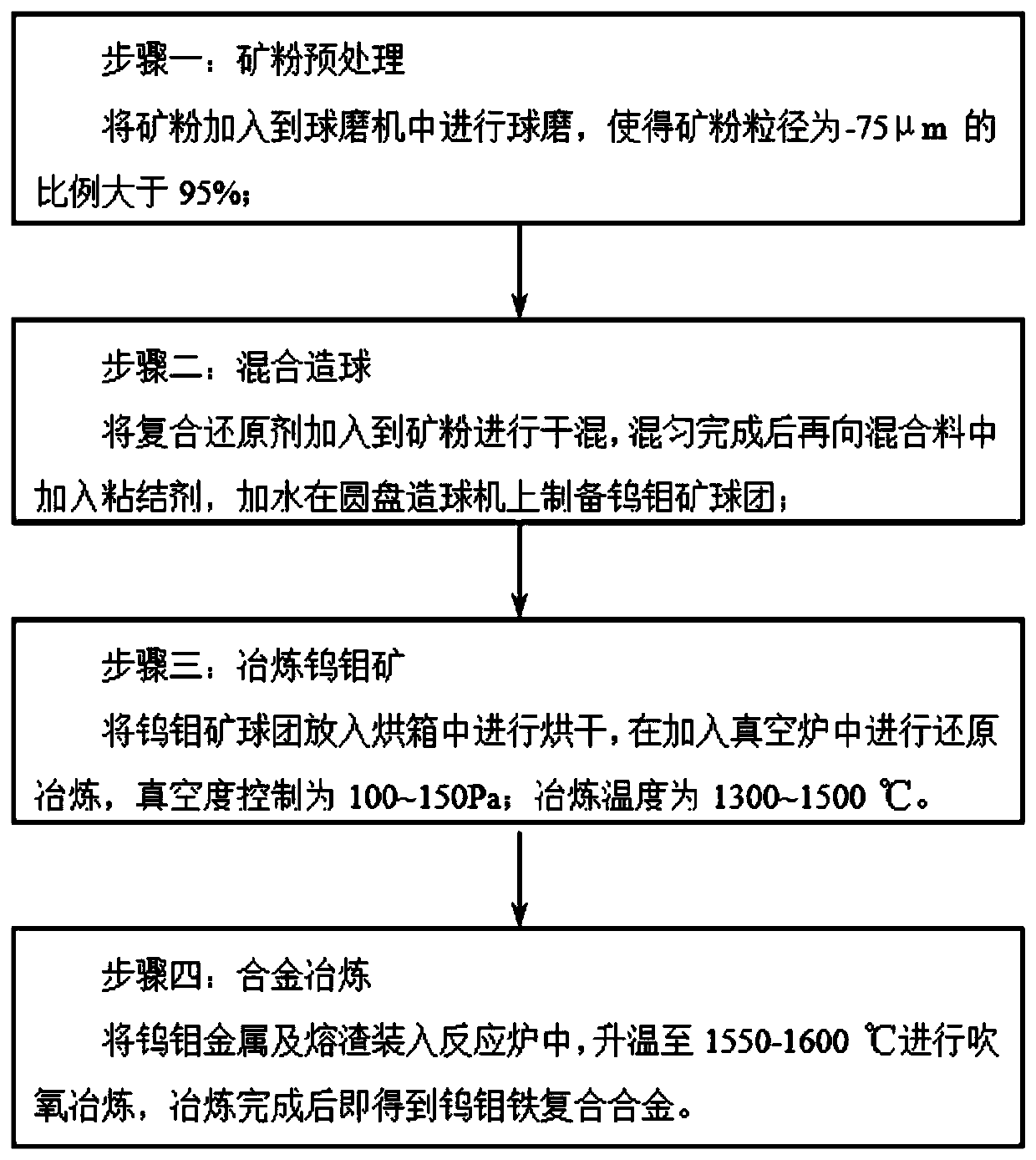

Method for smelting ferrotungston-molybdenum-iron alloy by adopting low-grade tungsten and molybdenum ore

ActiveCN107254590AStrong reductionImprove reduction efficiencyProcess efficiency improvementSlagResource utilization

The invention discloses a method for smelting a ferrotungston-molybdenum-iron alloy by adopting a low-grade tungsten and molybdenum ore, and belongs to the field resource utilization of low-grade tungsten and molybdenum ores. The method includes the steps that a compound reducing agent is added into the low-grade tungsten and molybdenum ore, the proportion of the compound reducing agent and the low-grade tungsten and molybdenum ore is phi, as the formula shows in an original text that, wherein the value of gamma is 5-6, and the alpha is the mass ratio of modified silicon carbide to modified quartz; and the value of kappa is as the formula showing in the original text; and the compound reducing agent and the low-grade tungsten and molybdenum ore are added into a vacuum furnace, tungsten and molybdenum metal and slag are obtained through reduction, the tungsten and molybdenum metal and the slag are contained in a reaction furnace, steel scrap is added into the reaction furnace, temperature rising smelting is conducted, and the ferrotungston-molybdenum-iron alloy is obtained after smelting is completed. According to the method for smelting the ferrotungston-molybdenum-iron alloy by adopting the low-grade tungsten and molybdenum ore, tungsten and molybdenum in the low-grade tungsten and molybdenum ore can be utilized sufficiently, the harmful elements like P in the alloy can be reduced, and the quality of the alloy is improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

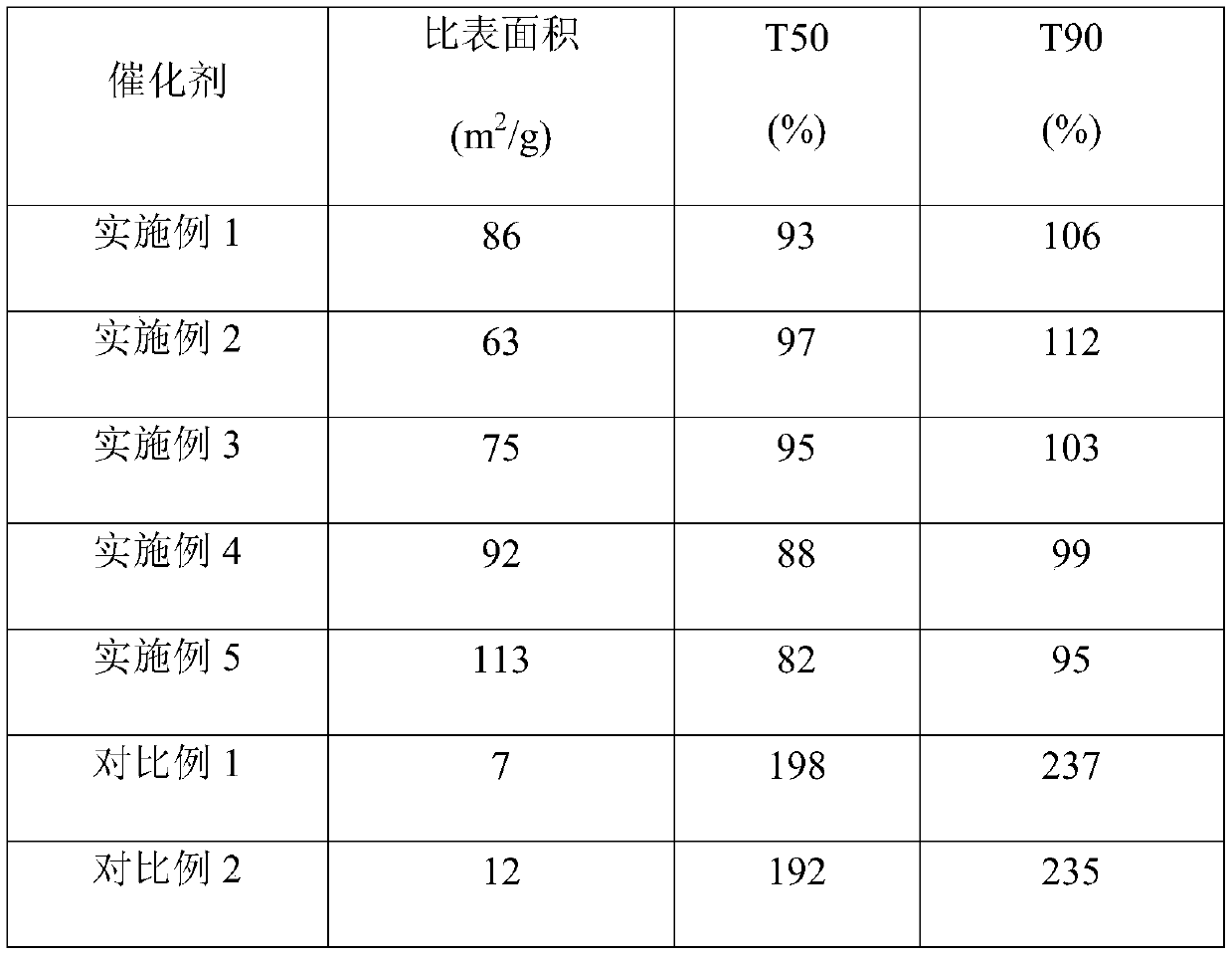

Monolithic VOCs catalytic combustion catalyst, and preparation method thereof

InactiveCN109701548AImprove stabilityImprove overall lifespanCatalyst activation/preparationIncinerator apparatusFiberAbsorption capacity

The invention provides a monolithic VOCs catalytic combustion catalyst, and a preparation method thereof. According to the preparation method, a high molecular fibrofelt is subjected to carbonizationprocessing at certain conditions so as to obtain a carbon fibrofelt, and activation pore-forming is carried out; introduction of active components into the activated fibrofelt through dipping is carried out, drying is carried out, and under inert gas protection, calcining processing at a certain temperature is carried out so as to obtain the monolithic VOCs catalytic combustion catalyst. The monolithic VOCs catalytic combustion catalyst is low in catalytic initial temperature, wide in working temperature range, high in catalytic activity, and long in service life. The preparation method is simple, convenient, and effective; operation is convenient; raw materials are widely available; the prepared monolithic VOCs catalytic combustion catalyst is stable in structure and excellent in heat conductivity; active component distribution is uniform; abundant pore structures are formed; specific absorption capacity on small molecular volatile organic compounds is achieved; a problem in the priorart that the activity of a conventional monolithic VOCs catalyst is poor is solved; preparation cost is low; product property is stable; and the preparation method is suitable for industrialized production.

Owner:BIOMINTEC ENVIRONMENT (SHANGHAI) CO LTD

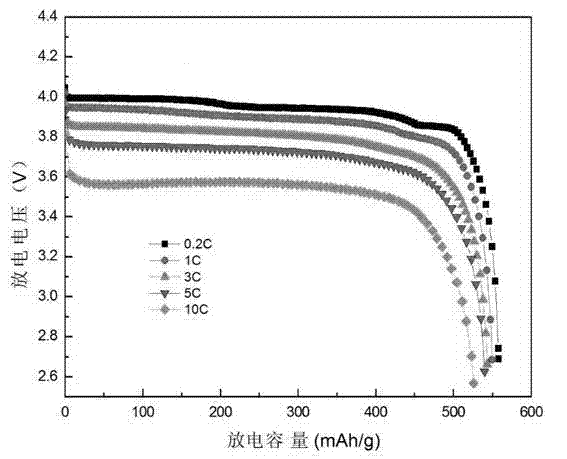

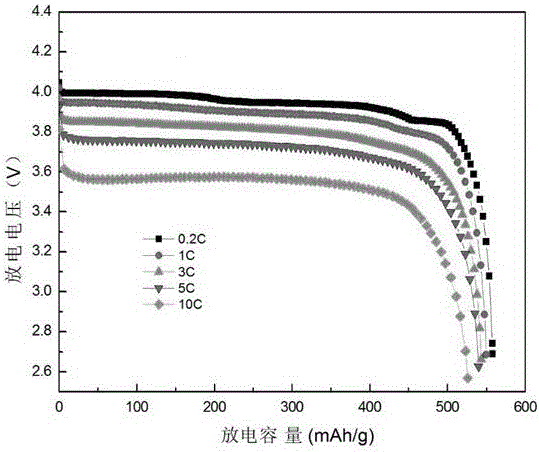

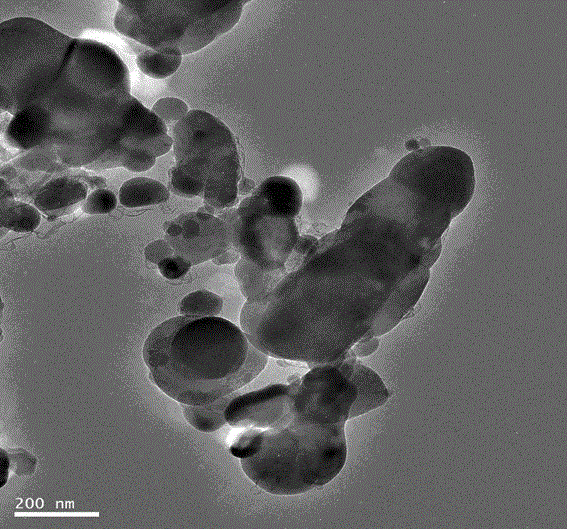

Preparation method of phosphate anode material

ActiveCN104743536AReduce reaction resistanceEvenly dopedCell electrodesPhosphorus compoundsPhosphateLithium-ion battery

The invention relates to the technical field of lithium ion batteries and provides a preparation method of a phosphate anode material, in order to solve the problem that product property is reduced and unstable since impurity elements are introduced during raw material solid phase method synthesis and resistance is relatively large in the dynamical process of doping reaction. The preparation method comprises the following steps: (1) carrying out mixed ball milling on a phosphate and a precursor for 2-8 hours to obtain a mixture; (2) pre-sintering the mixture in inert gas at 300-450 DEG C for 2-12h, thus obtaining a pre-sintered product; (3) carrying out mixed ball milling on the pre-sintered product, a lithium source and a carbon source for 2-8h; (4) sintering the product obtained after ball milling in the step (3) in inert gas at 500-900 DEG C for 4-24h, thus obtaining a sintering product; and (5) fine crushing the sintered product and sieving to obtain the phosphate anode material. With adoption of the preparation method disclosed by the invention, the discharge performance of the product is improved effectively and the homogeneity and stability of the product are also enhanced.

Owner:常州普格纳能源材料有限公司

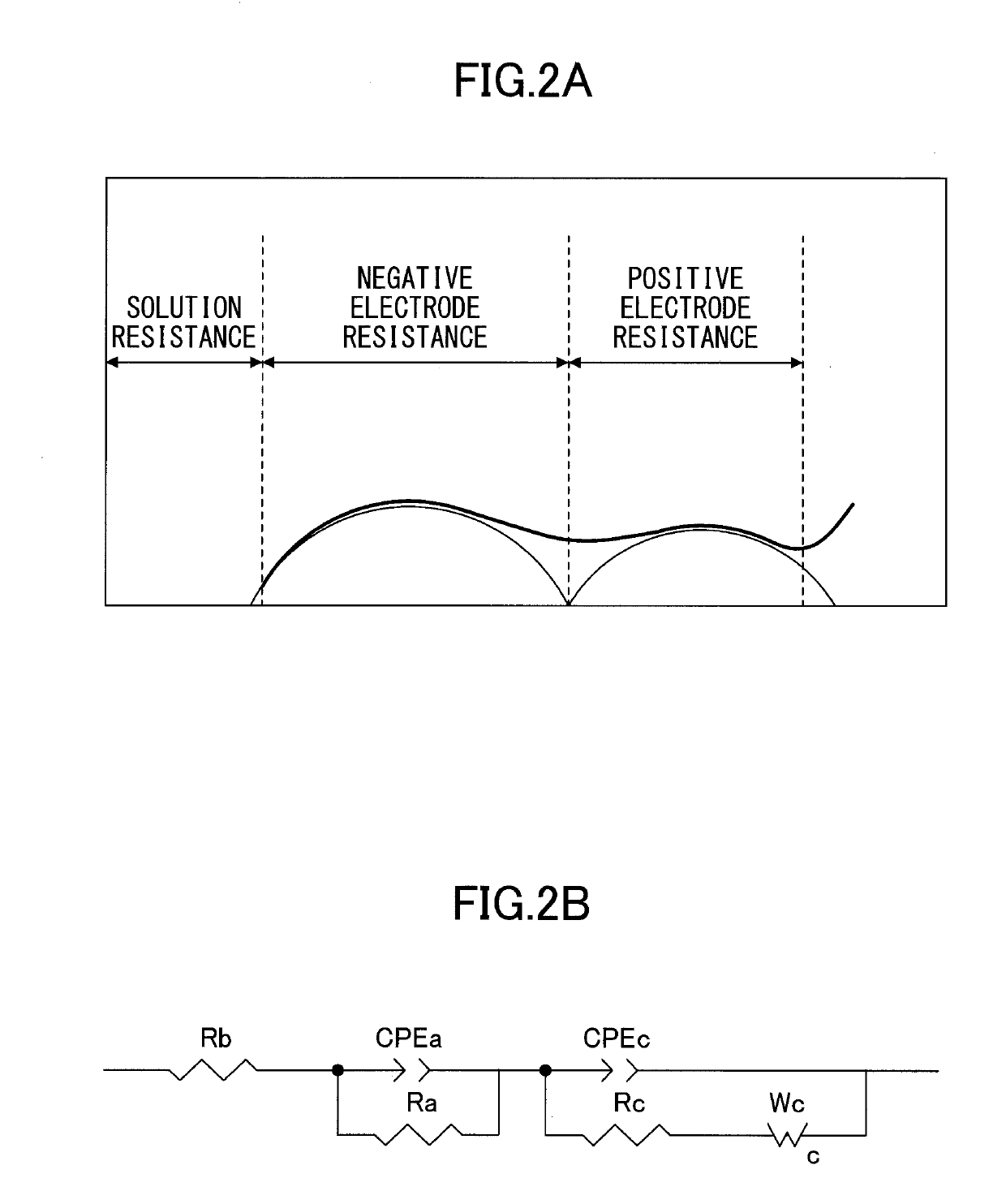

Lithium ion secondary battery

InactiveUS20180097234A1Lithium ion conductivityEasy to optimizeNanotechSecondary cellsLithiumElectrolyte

A lithium ion secondary battery includes a positive electrode, a negative electrode, and an electrolyte solution. At least one of the positive electrode and the negative electrode includes a magnetic field generating material.

Owner:TOYOTA JIDOSHA KK

Enzyme method for preparing gelatin

ActiveCN102329843BLarge specific surface areaTake advantage ofGlue/gelatin preparationFermentationCalcium hydroxideO-Phosphoric Acid

The invention relates to an enzyme method for preparing gelatin, which comprises the following steps of: pulverizing bone grains into bone meal, acidifying the bone meal by using phosphoric acid, and adding acid protease to hydrolyze; then, decoloring the solution by using hydrogen peroxide, and adjusting the pH value by using calcium hydroxide; and finally adding a flocculating agent. In the method provided by the invention, phosphoric acid is adopted for acidification, because a great amount of soluble calcium salts is formed, the enzymolysis reaction is mild. The defect that the enzymolysis end point of the finely ground collagen (ossein) enzymolysis method is difficult to control is overcome by controlling the end point of the enzymolysis reaction, so that the enzymolysis method for preparing gelatin is more practical.

Owner:安徽丰原集团有限公司

Preparation method of special nitrogen-doped molded active carbon for catalyst carrier

InactiveCN111186837AHigh mechanical strengthReduce reaction resistancePhysical/chemical process catalystsCarbon compoundsComposite materialActivated carbon

The invention relates to a preparation method of special nitrogen-doped molded active carbon for a catalyst carrier, wherein the special nitrogen-doped molded active carbon is high in strength, has anitrogen content of 0.5-10%, a specific surface area of 600-1200 cm<3> / g and a low ash content, and is prepared by taking wood biomass as a starting raw material through nitrogen doping, binder addition, mixing kneading, molding, carbonization and activation. The nitrogen-doped molded active carbon has the advantages of being high in specific surface area, developed in pore structure, high in strength and the like. The supported noble metal catalyst is small in particle size and high in catalytic activity, and shows conversion rate of 100% and product yield of more than 99% in a catalytic hydrogenation reaction of 1,8-dinitronaphthalene. The special nitrogen-doped molded active carbon has the advantages of wide raw material source, environment-friendly production process and the like.

Owner:NANJING FORESTRY UNIV

High-efficiency synthesis method for high-purity molybdenum disulfide

ActiveCN110357162AReduce reaction resistanceLow reaction temperatureMolybdenum sulfidesDecompositionQuartz

The invention discloses a high-efficiency synthesis method for high-purity molybdenum disulfide. The high-efficiency synthesis method comprises the following concrete steps: putting molybdenum trioxide powder or molybdenum dioxide powder and sulfur powder into a pulverizer for mixing and pulverizing so as to obtain a mixed raw material; and then filling a crucible with the mixed raw material, placing the crucible in the insulation sleeve of a microwave tube type controlled-atmosphere furnace, putting the insulation sleeve into a quartz tube, then sealing the two ends of the microwave tube typecontrolled-atmosphere furnace, introducing argon gas, turning one microwave heating, keeping warm, and carrying out cooling to room temperature so as to obtain high-purity molybdenum disulfide. According to the invention, molybdenum trioxide or molybdenum dioxide and sulfur are used as raw materials and subjected to microwave heating, and direct vulcanization is employed to synthesize high-puritymolybdenum disulfide, so synthesis in one shot is realizesd, and high pressure, thionation and decomposition are not needed, process flow is shortened, and production efficiency is improved; and molybdenum disulfide obtained by using the method has high purity and fine particle size, and is suitable for large-scale production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

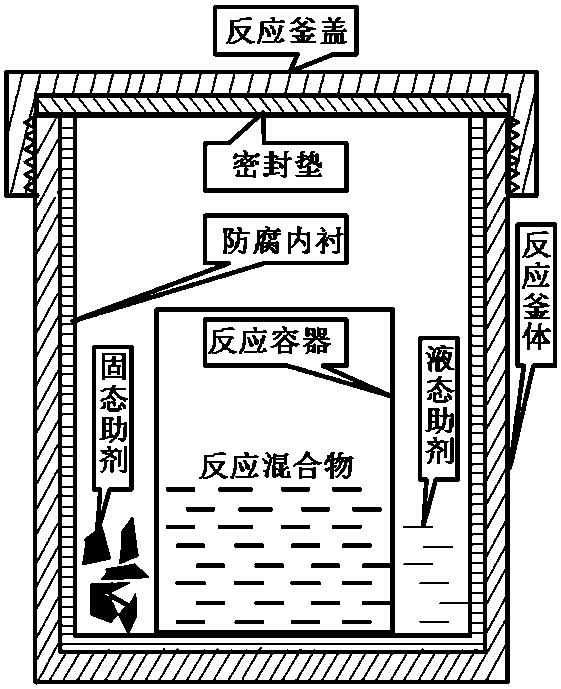

Method for assisted synthesis of porous composite material by using assistant transfer byproduct

InactiveCN110483557AFavorable for crystallization reactionHigh yieldGas treatmentOrganic compound preparationSolventReagent

The invention discloses a method for assisted synthesis of a porous composite material by using an assistant transfer byproduct. According to the method, an alkaline auxiliary agent is placed in a reaction device and is not in direct contact with reactants, and the amount-of-substance ratio of the auxiliary agent to by-product acid is controlled, so that the porous composite material is obtained through heating treatment in a sealed reaction kettle; and the grain size and distribution of the composite framework material are regulated and controlled; meanwhile, by-product acid in the mother liquor steam is in contact with an alkaline additive to form salt to be fixed, the salt is not returned to the mother liquor anymore; the salt can be used as a by-product for sale, while the mother liquor is directly used as a solvent to dissolve the next batch of reaction raw materials. The whole reaction process is easy to operate, low in operation cost, zero in three-waste emission, high in yieldand easy to realize large-scale production.

Owner:TAIYUAN UNIV OF TECH

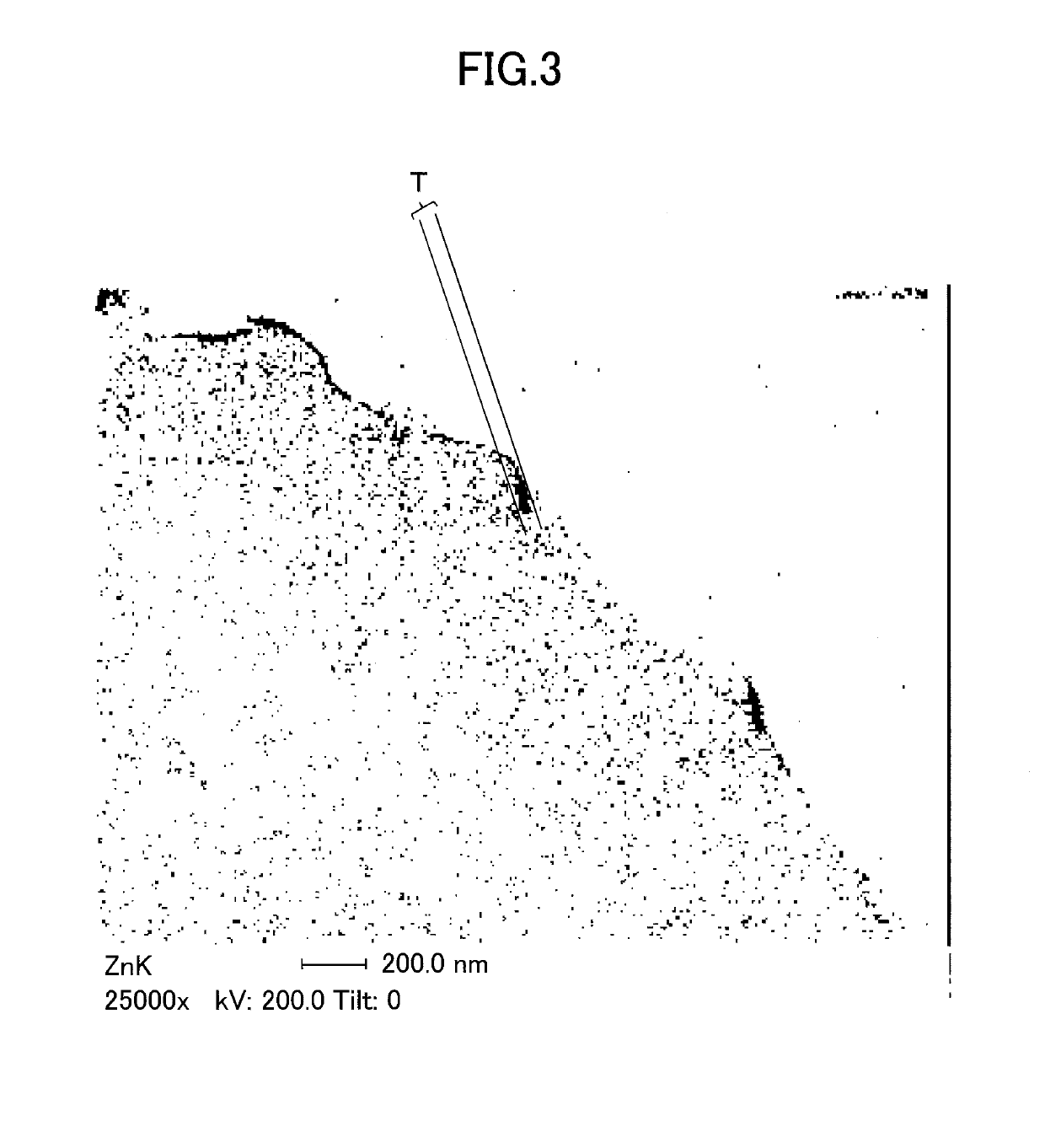

Positive electrode active material for nonaqueous electrolyte secondary batteries and method for producing positive electrode active material for nonaqueous electrolyte secondary batteries

ActiveUS20190198872A1Improve discharge capacityReduce reaction resistanceElectrode thermal treatmentSecondary cellsNiobiumManganese

A positive electrode active material for a nonaqueous electrolyte secondary battery includes a lithium-nickel-cobalt-zinc composite oxide powder that contains lithium (Li); nickel (Ni); cobalt (Co); element M, which is at least one element selected from the group consisting of manganese (Mn), vanadium (V), magnesium (Mg), molybdenum (Mo), niobium (Nb), silicon (Si), titanium (Ti), and aluminum (Al); and zinc (Zn). A molar element ratio (Li:Ni:Co:M) of the lithium-nickel-cobalt-zinc composite oxide powder satisfies Li:Ni:Co:M=z:(1-x-y):x:y (where 0.95≤z≤1.10, 0.05≤x≤0.35, and 0≤y≤0.10); a zinc content with respect to Li, Ni, Co, the element M, and oxygen in the lithium-nickel-cobalt-zinc composite oxide powder is greater than or equal to 0.01 mass % and less than or equal to 1.5 mass %; and at least a part of a surface of the lithium-nickel-cobalt-zinc composite oxide powder includes a zinc solid-solved region where zinc is solid-solved.

Owner:SUMITOMO METAL MINING CO LTD

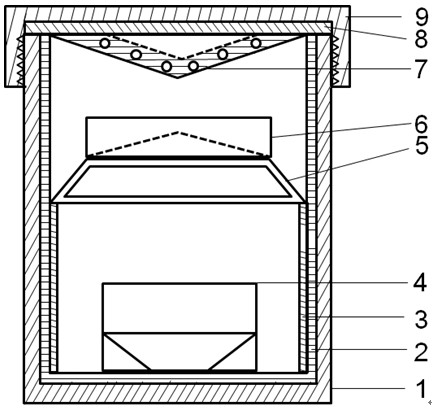

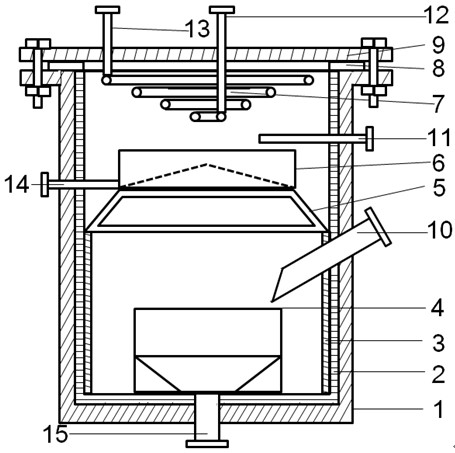

An anti-corrosion and high-temperature resistant reaction device integrating reaction and separation

ActiveCN110465253BImprove conversion rateHigh yieldChemical/physical/physico-chemical processesStrong acidsProcess engineering

The invention discloses an anti-corrosion and high-temperature-resistant reaction device integrating reaction and separation, which comprises a reaction kettle body, an anti-corrosion layer, a bracket, a reactant container, a separation aid box, a condensation conical frustum, a sealing gasket and a reaction kettle cover; Additional feed pipes for reactants, auxiliary agent input pipes, coolant inlet pipes, coolant outlet pipes, auxiliary agent vent pipes and product outlet pipes are added; among them, the condensate conical frustum is pre-embedded with a coil cooling structure, and the separation aid The outer bottom of the kit is an upward convex structure. This device can be used under the conditions of strong acid, strong alkali medium, high temperature and high pressure. The by-products are transferred and transformed, which reduces the reaction resistance and improves the conversion rate of materials in the kettle. , the product yield is high, the mother liquor is directly used for the next batch of synthesis, the reaction and separation are carried out simultaneously, the separation process does not need to consume additional transportation and heating energy, no need to build special separation equipment, energy saving, space saving, simple process, Economical and reasonable, conducive to engineering strengthening.

Owner:TAIYUAN UNIV OF TECH

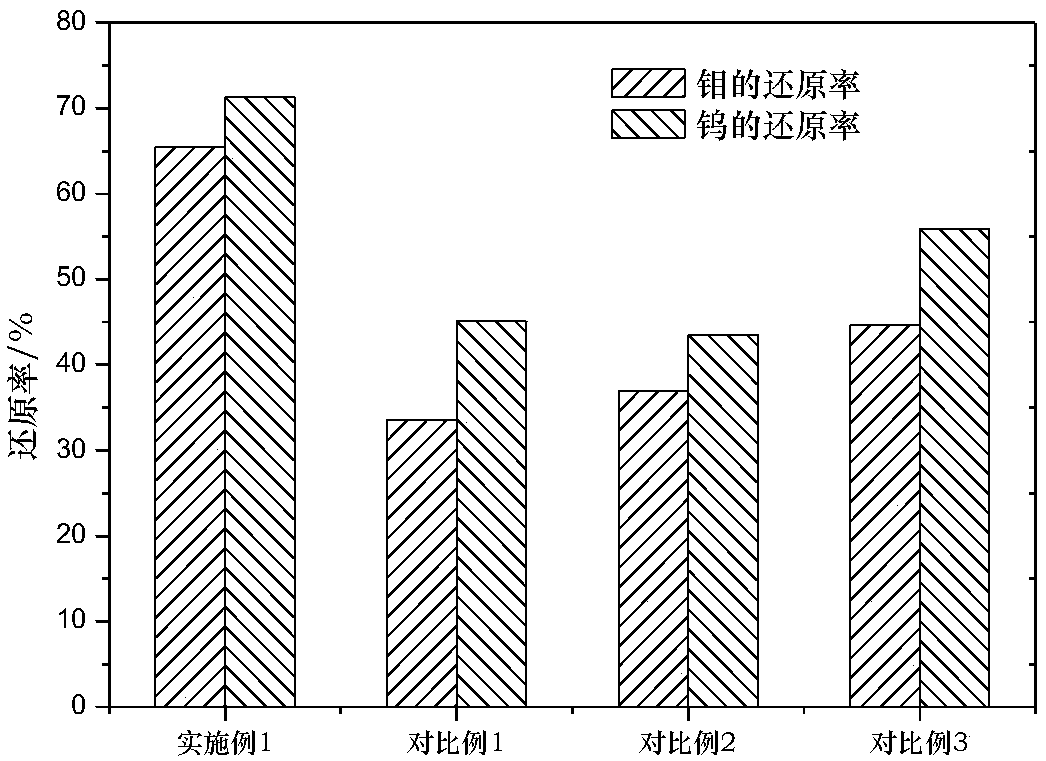

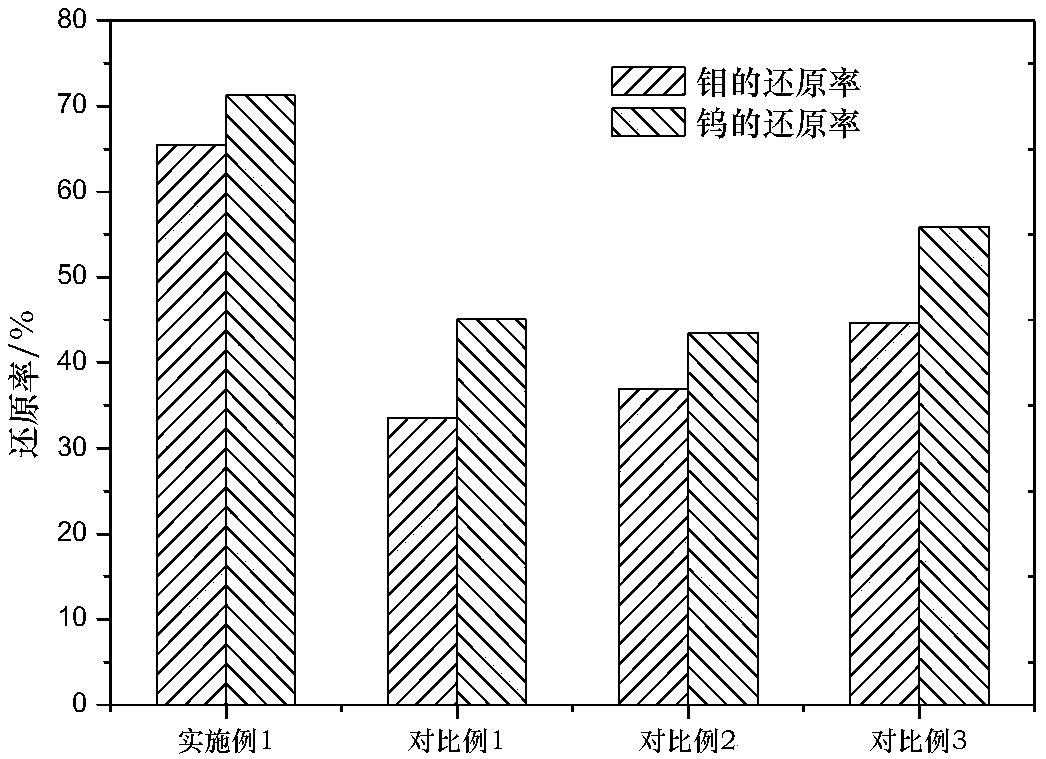

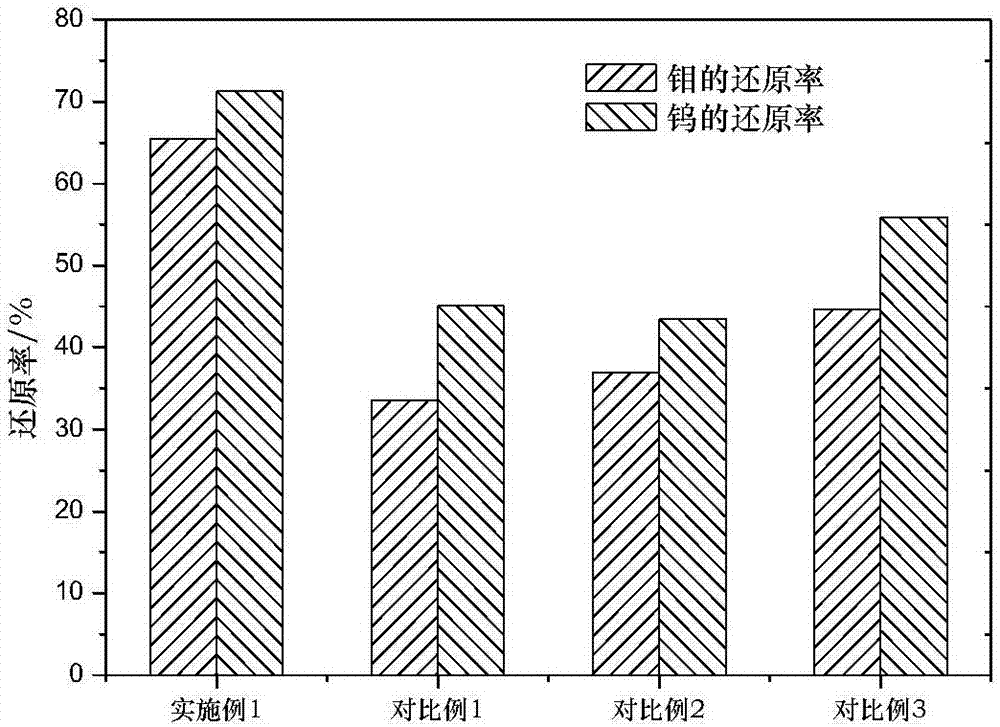

A composite reducing agent for smelting low-grade tungsten-molybdenum ore and its smelting method

The invention discloses a compound reducing agent for smelting low-grade tungsten and molybdenum ores and a smelting method thereof, and belongs to the field of low-grade tungsten and molybdenum ore resource utilization. The compound reducing agent comprises modified silicon carbide, modified quartz and an addition agent. The modified silicon carbide is a mixture of silicon carbide powder and silica powder. The surface of the modified quartz is coated with a coating component, and the coating component includes asphalt. The addition agent comprises coke powder. According to the compound reducing agent for smelting the low-grade tungsten and molybdenum ores and the smelting method thereof, under the mutual promotion effect of the modified silicon carbide, the modified quartz and the addition agent, the reducing action on the low-grade tungsten and molybdenum ores is good; the silica powder coated on the surface of the modified silicon carbide has good reaction performance, the modified silicon carbide can respond to intervention quickly under the promotion effect of the modified quartz and further be reacted with CaMoO4 and CaWO4, the modified silicon carbide can further produce CO gas with reducibility in the reacting process, and reducing efficiency of the low-grade tungsten and molybdenum ores can be improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

A preparation method of cobalt-modified porous biochar catalyst for mercury removal

ActiveCN109529845BWide variety of sourcesWide range of sources, cheap and easy to getGas treatmentDispersed particle separationPtru catalystCarbonization

The invention discloses a preparation method of a cobalt-modified porous biochar catalyst for mercury removal, and belongs to the technical field of coal-fired flue gas mercury emission control. The preparation method is as follows: use fir as the biochar carrier, and use Co 3 O 4 As the active ingredient, the laying of crystal seed layer is achieved through sol-gel method, and Co is achieved through hydrothermal treatment. 3 O 4 The growth of nanocrystals, and finally through carbonization treatment, a supported catalyst with highly dispersed active ingredients is obtained. The invention has a wide range of sources of raw materials, a simple and controllable process, and mild operating conditions. The obtained Co-modified porous biochar catalyst has a mercury removal efficiency of more than 80% at different temperatures.

Owner:DALIAN UNIV OF TECH

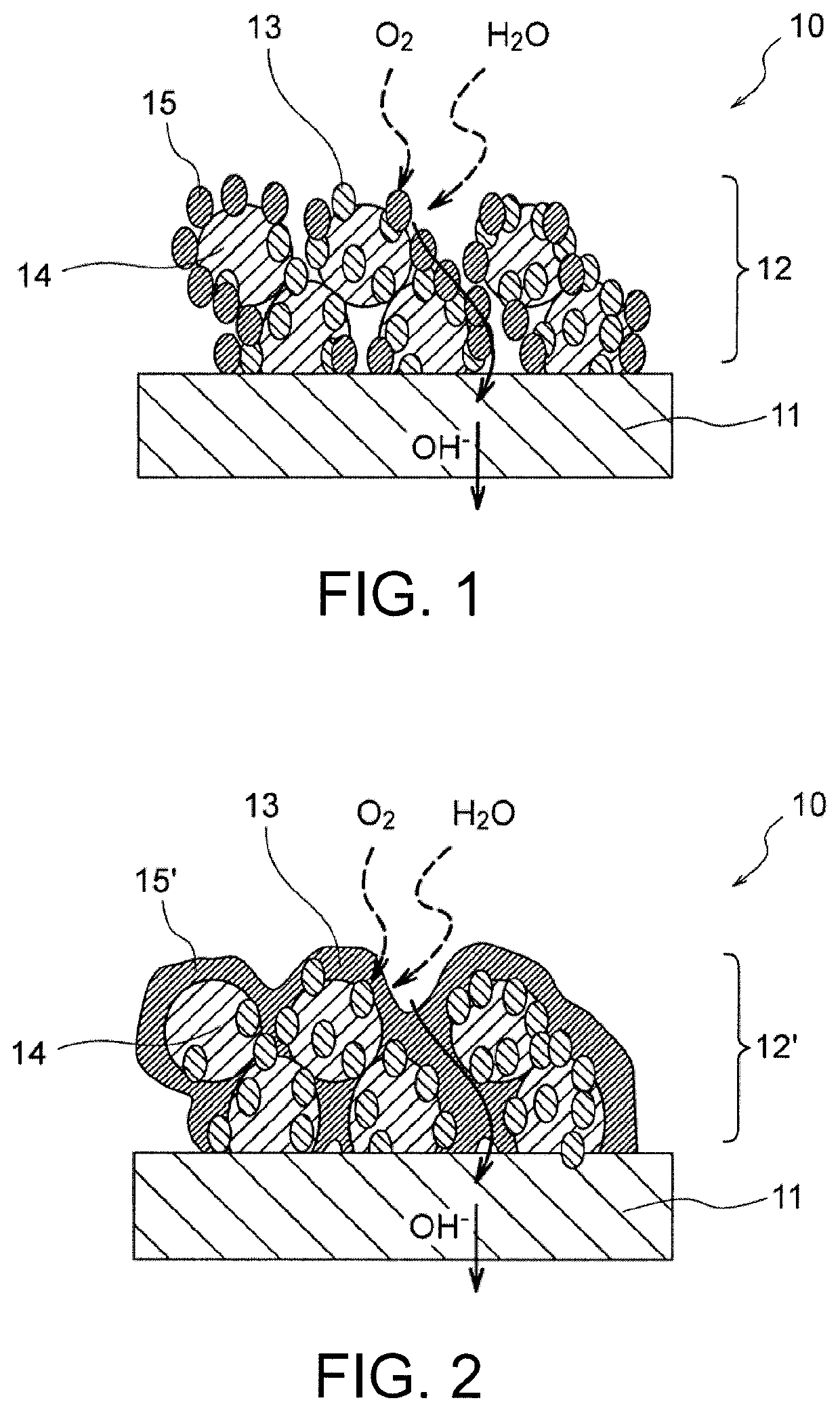

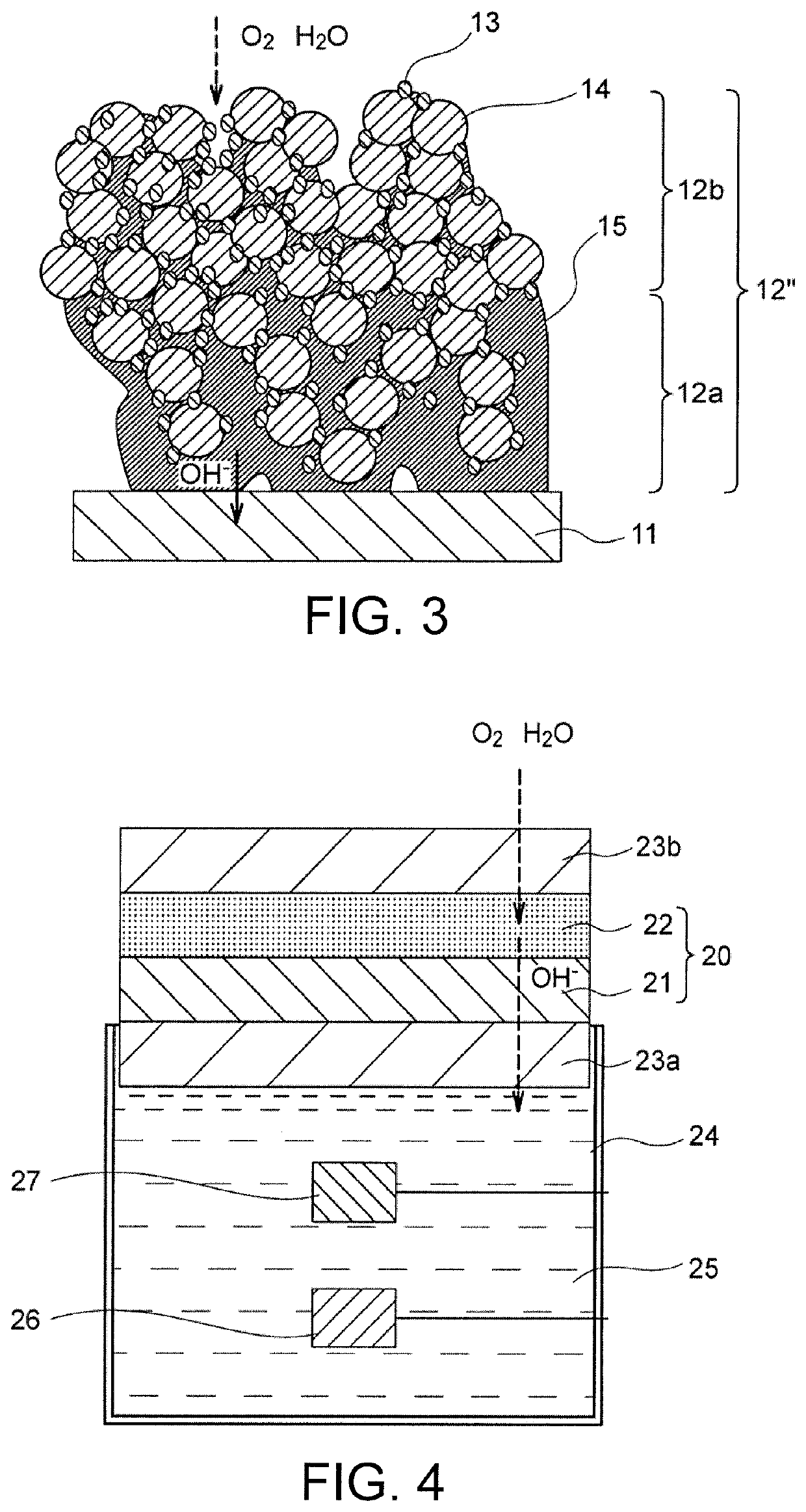

Air electrode for metal-air battery

ActiveUS10892530B2Reduce reaction resistanceReduce resistanceFuel and primary cellsFuel and secondary cellsPtru catalystConductive materials

Disclosed is an air electrode for a metal-air battery, the air electrode including a separator composed of a hydroxide-ion-conductive inorganic solid electrolyte being a dense ceramic material, and an air electrode layer disposed on the separator and containing an air electrode catalyst, an electron-conductive material, and a hydroxide-ion-conductive material, or containing an air electrode catalyst also serving as an electron-conductive material and a hydroxide-ion-conductive material. According to the present invention, the reaction resistance of the air electrode including the dense ceramic separator can be significantly reduced in a metal-air battery while ensuring the desired characteristics of the dense ceramic separator.

Owner:NGK INSULATORS LTD

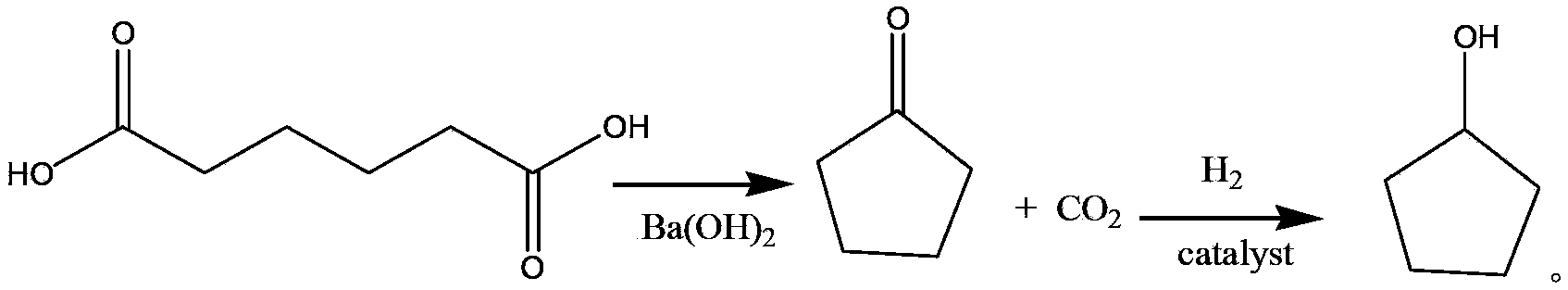

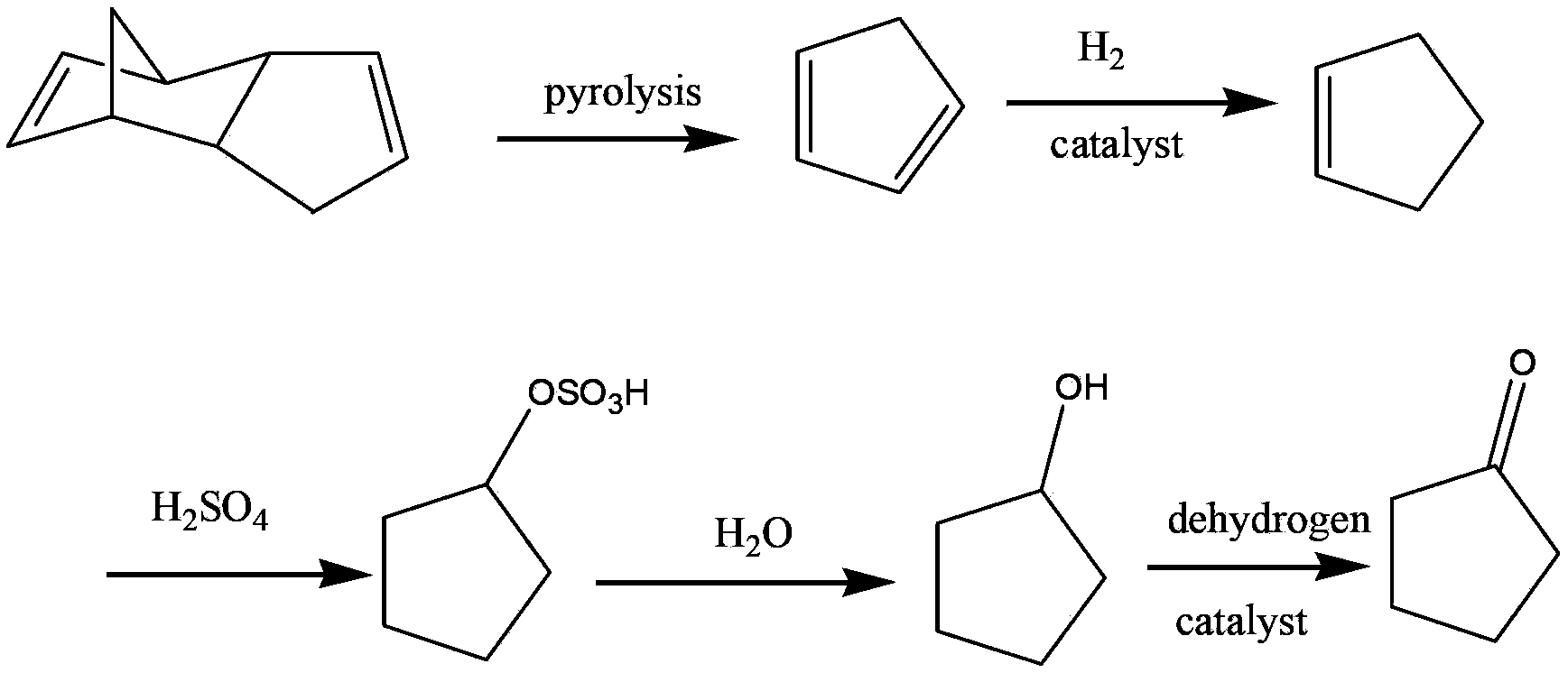

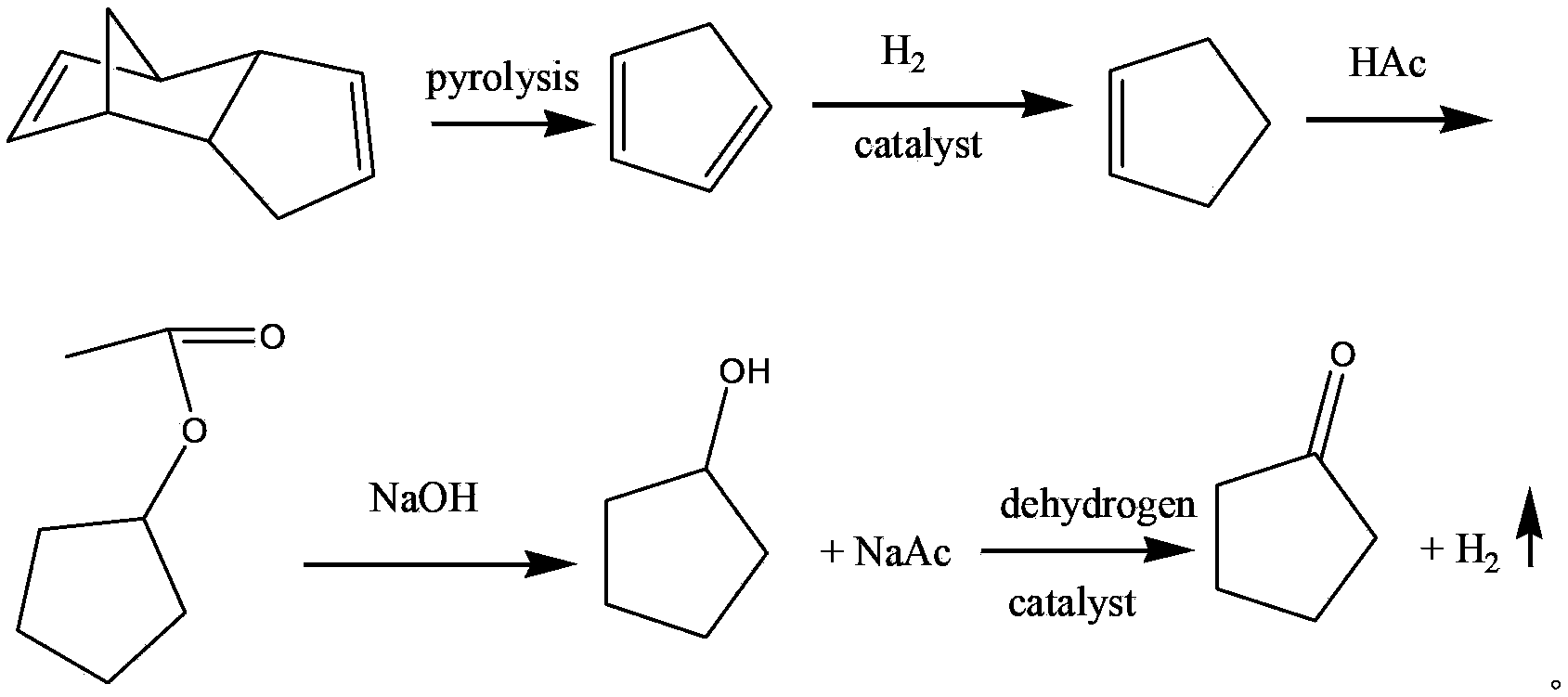

Cyclopentanol green synthetic method

InactiveCN103130630BHigh yieldReduce regenerationOrganic compound preparationCarbonyl compound preparationCyclopenteneSodium acetate

The invention discloses a cyclopentanone green synthetic method, which is characterized by comprising the following steps: 1)a by-product dicyclopentadiene is taken as a raw material during a process of cracking petroleum to prepare ethane, the processes of pyrolysis, quick separation and cooling to obtain cyclopentadiene; 2)under the effect of a first catalyst on cyclopentadiene, an auxiliary agent with mass fraction with 0.8% is added for selective hydrogenation to prepare cyclopentene; 3)then cyclopentene and acetic acid are performed with a esterification reaction to prepare et hanoic acid cyclopentyl ester; 4) then et hanoic acid cyclopentyl ester and sodium hydroxide are reacted to generate cyclopentanol; and 5)a constant temperature crystallization technology is employed, a crystallization kettle with cyclopentanol is continuously added in a high temperature sodium acetate solution, under the effect of a second catalyst, the crystal is continuously centrifuged, a large mother liquor is used for circularly cooling and performing heat exchange and then is returned to a crystallization kettle, and the catalysis and dehydrogenation are carried out to prepare the cyclopentanone. The cyclopentanone green synthetic method has the advantages of high selectivity, high yield, low energy consumption and less side reaction, and can solve the problems of corrosion and environmental pollution.

Owner:张若煜

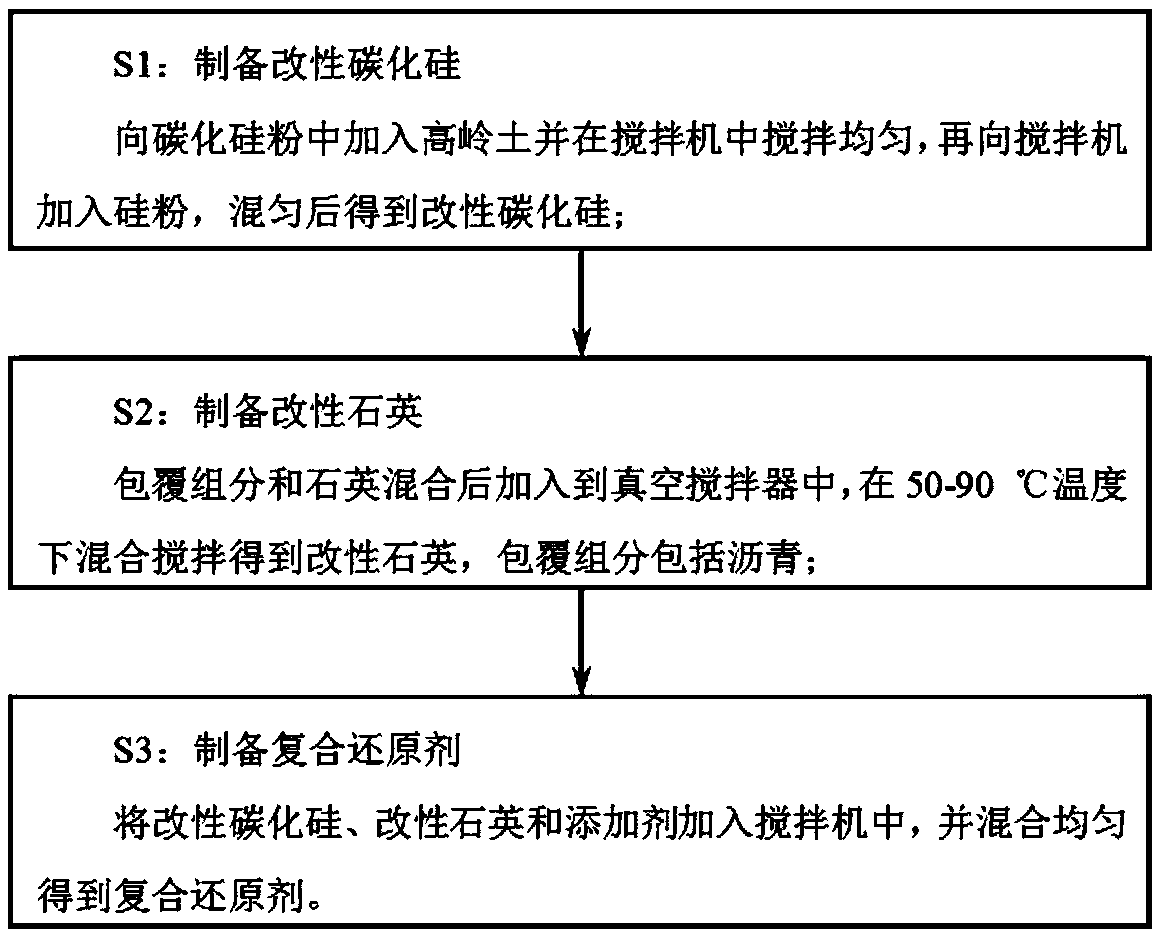

A preparation method of composite reducing agent and its method for smelting

The invention discloses a preparation method of a composite reducing agent and a method for smelting the same, belonging to the field of resource utilization of low-grade tungsten-molybdenum ore. In the present invention, the modified silicon carbide, modified quartz and additives are put into a mixer and mixed uniformly, the mixing temperature is 30-40°C, the modified silicon carbide is a mixture of silicon carbide powder and silicon powder, and the modified quartz It is quartz coated with a coating component on the surface, the coating component includes asphalt; the additive includes coke powder. The composite reducing agent prepared by the invention has a good reduction effect on low-grade tungsten-molybdenum ore; the silicon powder coated on the surface of the modified silicon carbide has good reaction performance, and can quickly intervene in the reaction under the promotion of the modified quartz, And react with CaMoO4, CaWO4, modified silicon carbide also produces reducing CO gas during the reaction process, which can improve the reduction efficiency of low-grade tungsten-molybdenum ore.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

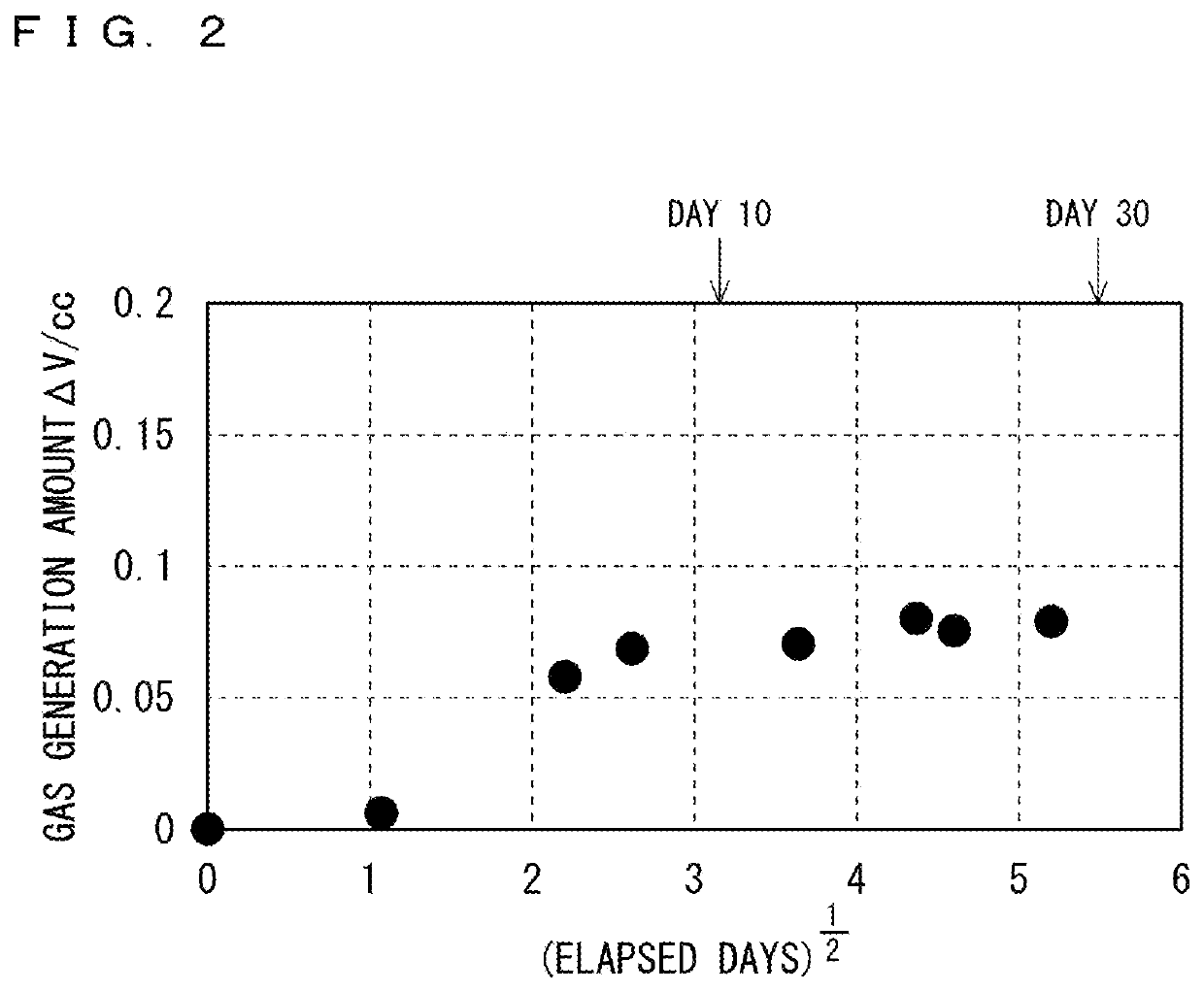

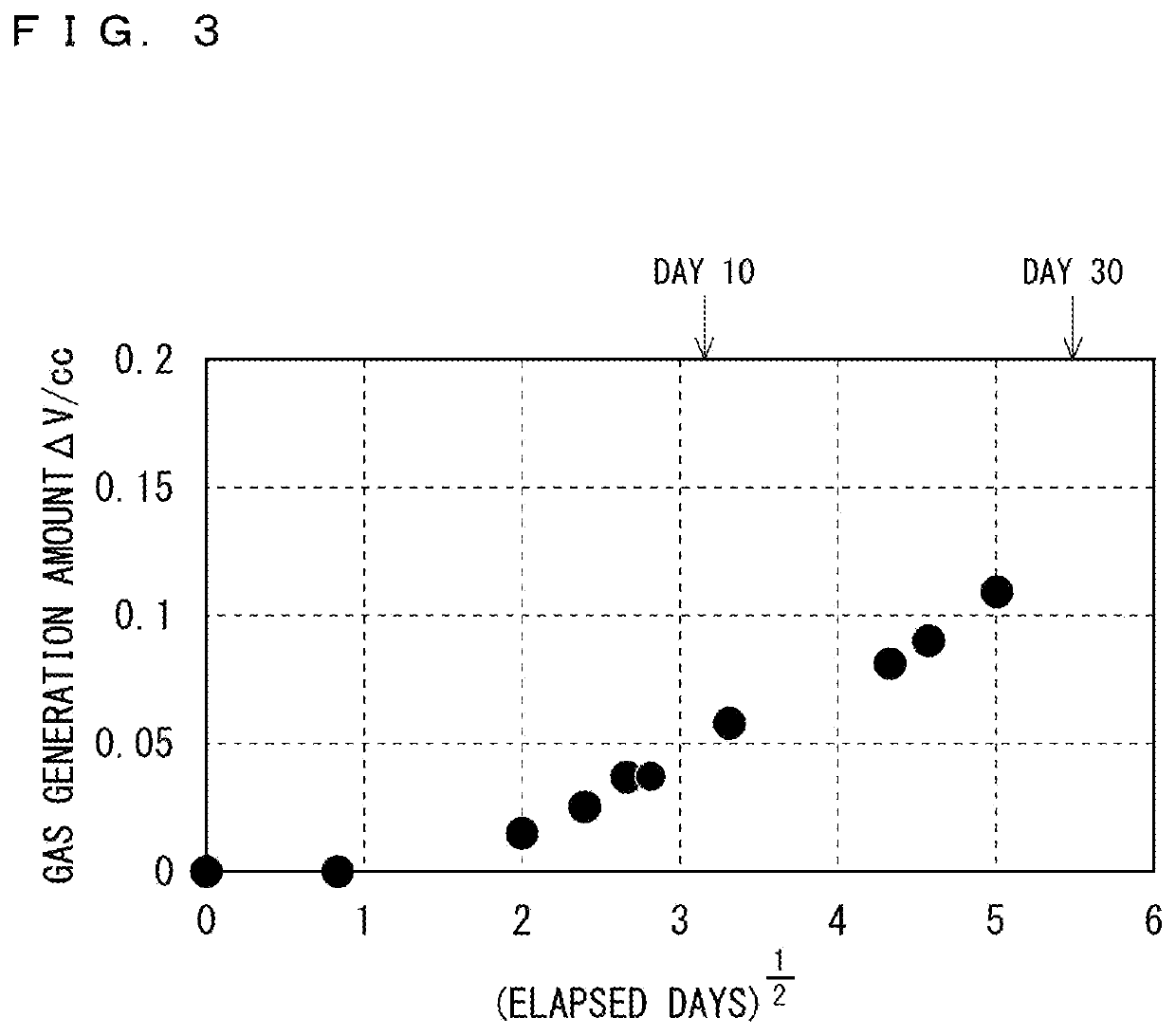

Lithium composite oxide sintered body plate

InactiveUS20210336248A1Reduce reaction resistanceSuppress gas productionElectrode thermal treatmentPositive electrodesComposite oxideComposite material

A lithium composite oxide sintered body plate includes a porous structure in which a plurality of primary particles of a lithium composite oxide having a layered rock-salt structure are bonded is included, in which a porosity is 15 to 50%, a ratio of the primary particles whose average inclination angle being an average value of angles between a (003) plane of the plurality of primary particles and a plate surface of the sintered body plate is more than 0° and 30° or less is 60% or more, one or more additive elements selected from Nb, Ti, W are contained, and an addition amount of the one or more additive elements to an entire of the sintered body plate is 0.01 wt % or more and 2.0 wt % or less.

Owner:NGK INSULATORS LTD

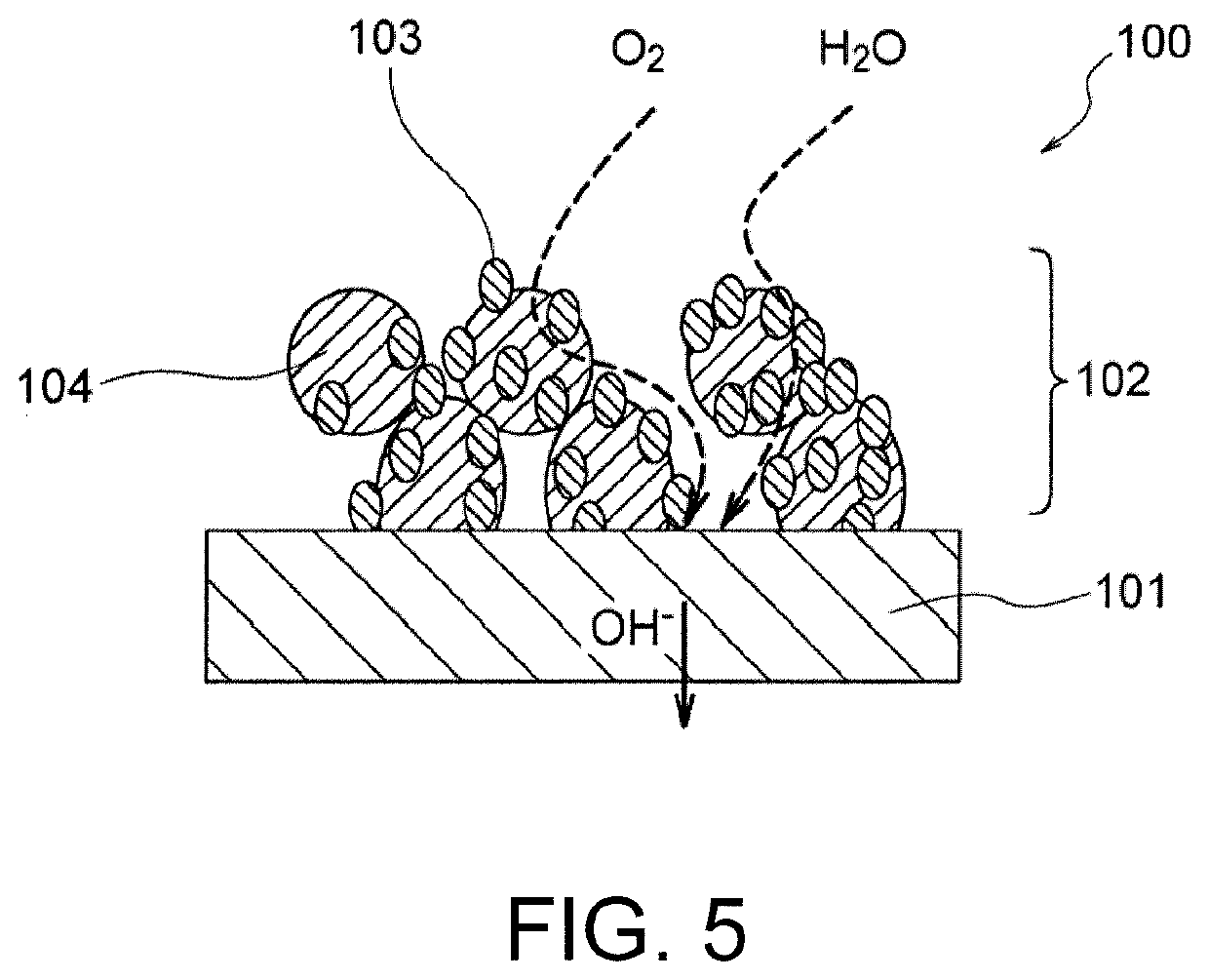

Solid oxide fuel cell

ActiveUS8945789B2Reduce reaction resistanceReduce resistanceFinal product manufactureActive material electrodesFuel cellsEngineering

The present invention provides a solid oxide fuel cell (SOFC) including a porous fuel electrode which allows reaction of a fuel gas to proceed and which is formed of Ni and YSZ, a porous air electrode which allows reaction of an oxygen-containing gas to proceed, and a dense solid electrolyte membrane which is provided between the fuel electrode and the air electrode and which has an interface with the fuel electrode. In the fuel electrode, Ni grains present in a region located within 3 μm from the interface (i.e., a “near-interface region”) have a mean size of 0.28 to 0.80 μm, YSZ grains present in the near-interface region have a mean size of 0.28 to 0.80 μm, and pores present in the near-interface region have a mean size of 0.10 to 0.87 μm. Thus, the fuel electrode of the SOFC exhibits low reaction resistance.

Owner:NGK INSULATORS LTD

A method for smelting tungsten-molybdenum ferroalloy using low-grade tungsten-molybdenum ore

ActiveCN107254590BStrong reductionImprove reduction efficiencyProcess efficiency improvementSlagResource utilization

The invention discloses a method for smelting a ferrotungston-molybdenum-iron alloy by adopting a low-grade tungsten and molybdenum ore, and belongs to the field resource utilization of low-grade tungsten and molybdenum ores. The method includes the steps that a compound reducing agent is added into the low-grade tungsten and molybdenum ore, the proportion of the compound reducing agent and the low-grade tungsten and molybdenum ore is phi, as the formula shows in an original text that, wherein the value of gamma is 5-6, and the alpha is the mass ratio of modified silicon carbide to modified quartz; and the value of kappa is as the formula showing in the original text; and the compound reducing agent and the low-grade tungsten and molybdenum ore are added into a vacuum furnace, tungsten and molybdenum metal and slag are obtained through reduction, the tungsten and molybdenum metal and the slag are contained in a reaction furnace, steel scrap is added into the reaction furnace, temperature rising smelting is conducted, and the ferrotungston-molybdenum-iron alloy is obtained after smelting is completed. According to the method for smelting the ferrotungston-molybdenum-iron alloy by adopting the low-grade tungsten and molybdenum ore, tungsten and molybdenum in the low-grade tungsten and molybdenum ore can be utilized sufficiently, the harmful elements like P in the alloy can be reduced, and the quality of the alloy is improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

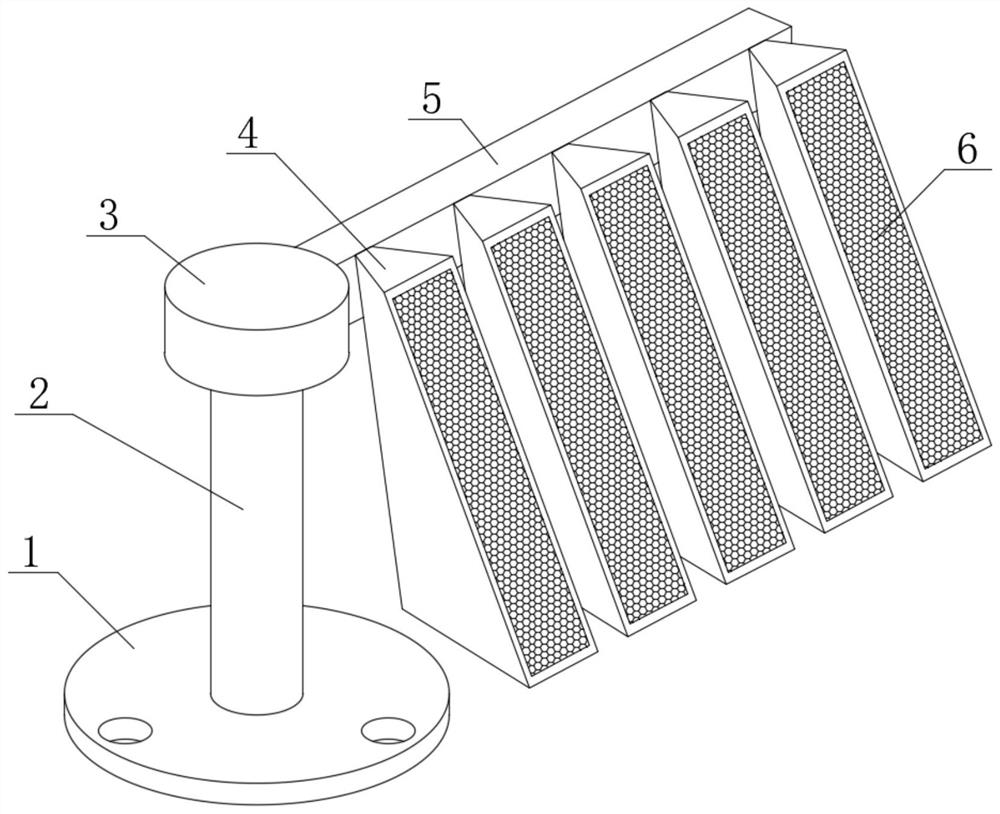

Floating algae collecting device for sewage treatment

InactiveCN111646528AAvoid cloggingImprove collection efficiencyTreatment involving filtrationGrain treatmentsSewage treatmentAlgae

The invention belongs to the technical field of sewage disposal, particularly relates to a floating algae collecting device for a sewage disposal, and provides the floating algae collecting device forsolving the problem that algae block algae inlets in the algae removal process of an existing algae removal device running on the water surface: the floating algae collecting device comprises a fixedbase, and the middle of the top of the fixed base is connected with a vertically arranged supporting column through a bolt; the top of the circumferential outer wall of the supporting column is sleeved with a horizontally-arranged rotating top plate, and a horizontal driving cavity is formed in the position, located at the top of the supporting column, of the rotating top plate. According to thefloating algae collecting device, a rotary crushing middle shaft is arranged between the inner walls of the two ends of an algae removing box, crushing rods on the circumference of the crushing middleshaft can crush collected algae, the algae can be conveniently collected into the algae collecting box, the algae are prevented from being wound in the algae inlet holes of the algae removing box andblocking the algae inlet holes, and the collecting efficiency is improved; and the crushing middle shaft is driven by rotation of a bevel gear set and a rotating top plate, so that the algae collecting efficiency is improved.

Owner:李燕

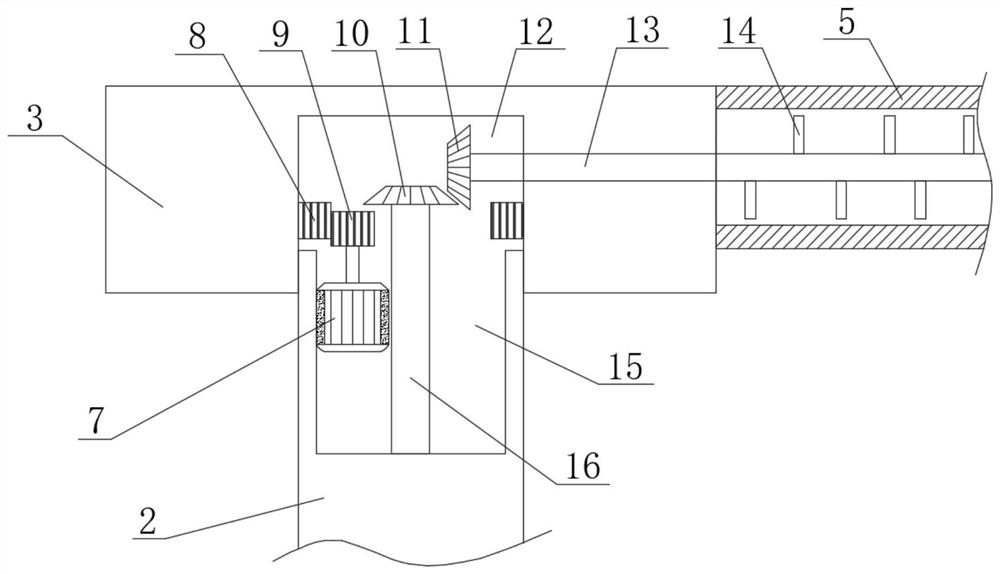

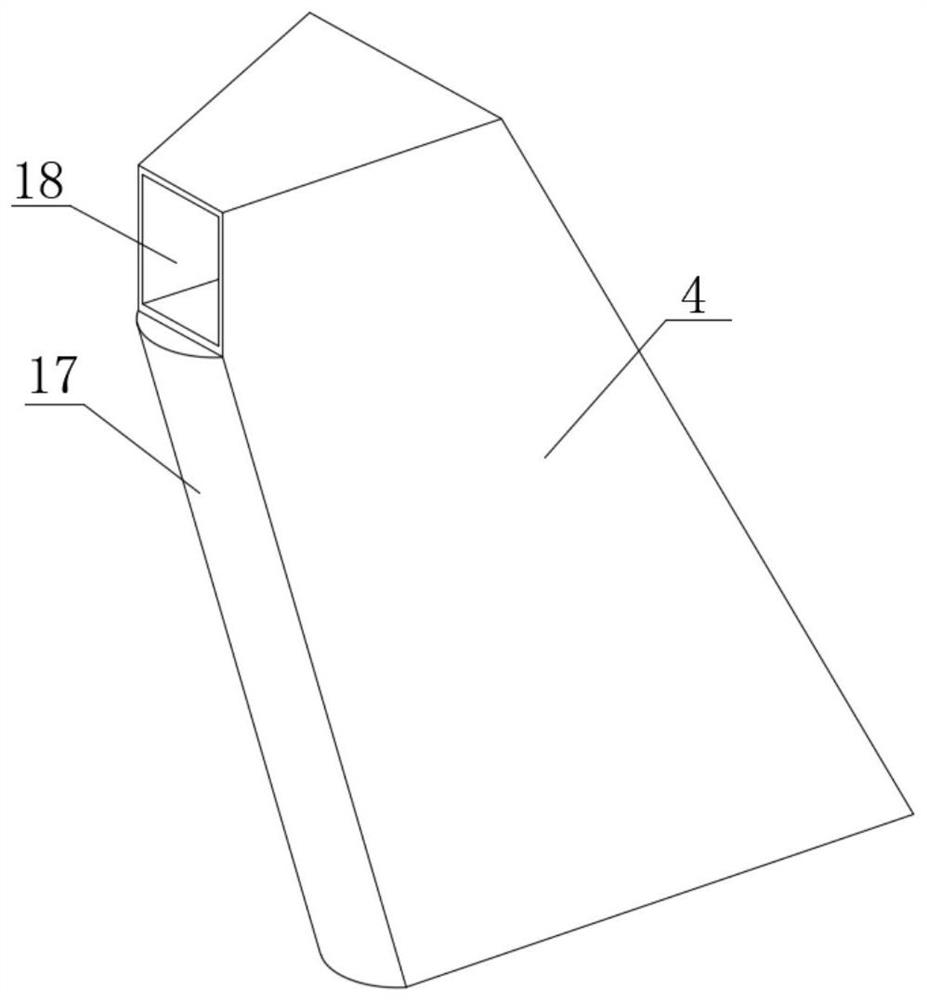

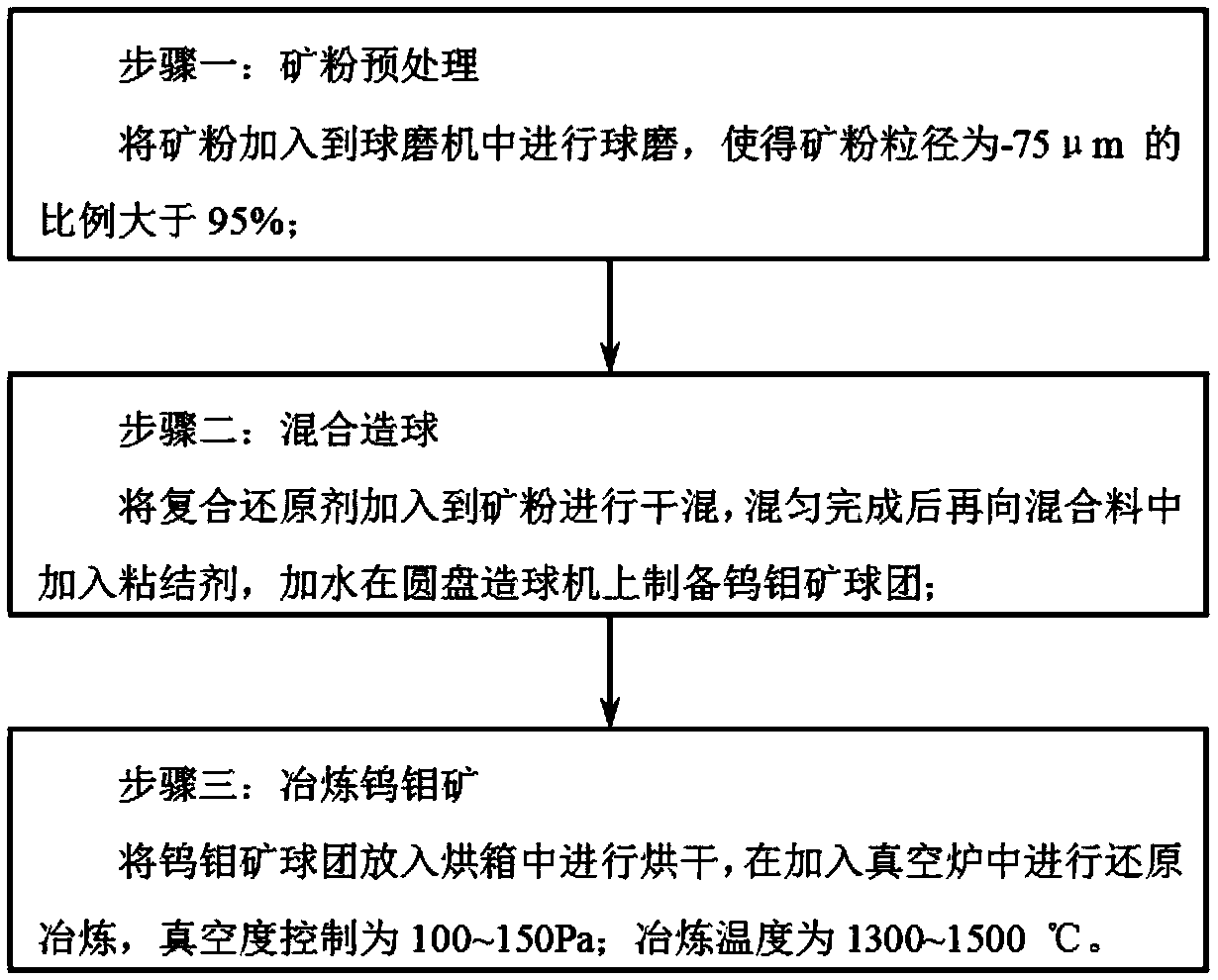

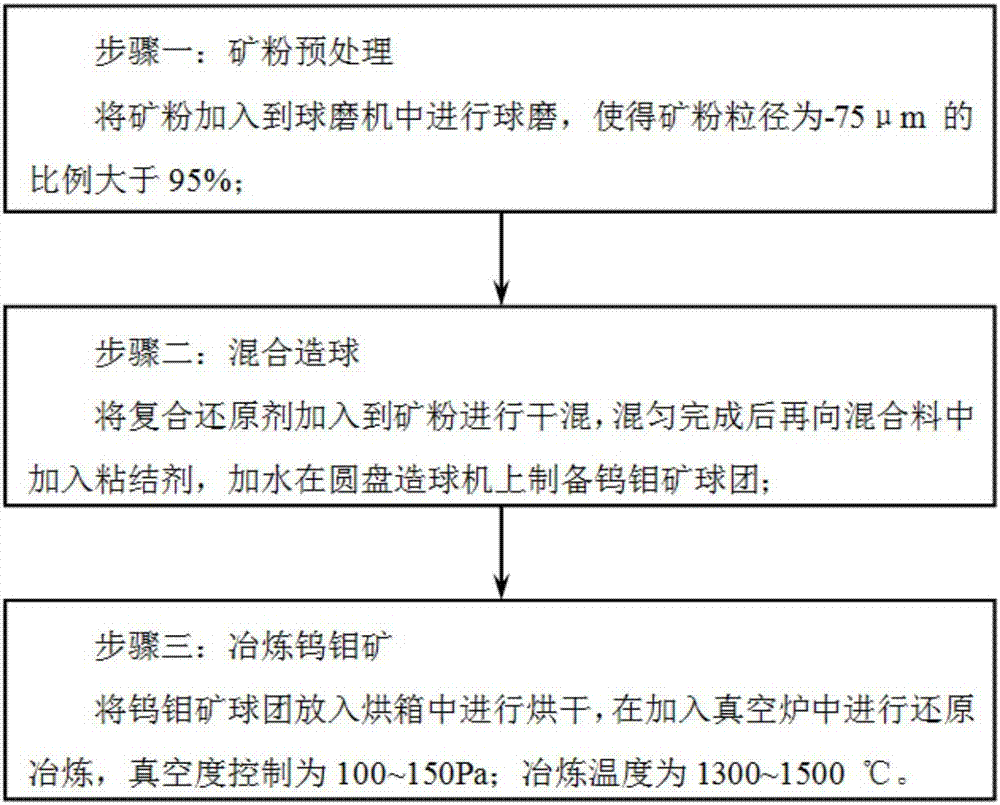

A method for smelting low-grade tungsten-molybdenum ore and a method for simultaneously recovering phosphorus

ActiveCN107267781BStrong reductionImprove reduction efficiencyPhosphorus compoundsReduced propertiesBall mill

The invention discloses a method for smelting low-grade tungsten and molybdenum ore and a method for recycling phosphorus simultaneously during smelting of the low-grade tungsten and molybdenum ore and belongs to the field of resourceful utilization of the low-grade tungsten and molybdenum ore. The method for smelting the low-grade tungsten and molybdenum ore specifically includes the steps that (1) ore powder pre-treatment is performed, specifically, ore powder is added into a ball mill for ball milling; (2) mixing and pelletizing are performed, specifically, a composite reducing agent is added into the ore powder for dry mixing, a bonder is added into a mixture obtained after uniform mixing is finished, and tungsten and molybdenum ore pellets are prepared on a disc pelletizing machine; and (3) smelting of the tungsten and molybdenum ore is performed, specifically, the tungsten and molybdenum ore pellets are dried in a drying oven and then added into a vacuum furnace for reducing smelting, and the smelting temperature ranges from 1300 DEG C to 1500 DEG C. By means of the method for smelting the low-grade tungsten and molybdenum ore, silicon powder wrapping the surface of modified silicon carbide of the composite reducing agent is good in reaction property and can rapidly intervene in the reaction under promotion of modified quartz, CO with the reducing property can be generated during reaction of the modified silicon carbide, and the reducing efficiency of the low-grade tungsten and molybdenum ore can be improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

A kind of preparation method of phosphate series cathode material

ActiveCN104743536BReduce reaction resistanceEvenly dopedCell electrodesPhosphorus compoundsPhosphateLithium-ion battery

The invention relates to the technical field of lithium ion batteries and provides a preparation method of a phosphate anode material, in order to solve the problem that product property is reduced and unstable since impurity elements are introduced during raw material solid phase method synthesis and resistance is relatively large in the dynamical process of doping reaction. The preparation method comprises the following steps: (1) carrying out mixed ball milling on a phosphate and a precursor for 2-8 hours to obtain a mixture; (2) pre-sintering the mixture in inert gas at 300-450 DEG C for 2-12h, thus obtaining a pre-sintered product; (3) carrying out mixed ball milling on the pre-sintered product, a lithium source and a carbon source for 2-8h; (4) sintering the product obtained after ball milling in the step (3) in inert gas at 500-900 DEG C for 4-24h, thus obtaining a sintering product; and (5) fine crushing the sintered product and sieving to obtain the phosphate anode material. With adoption of the preparation method disclosed by the invention, the discharge performance of the product is improved effectively and the homogeneity and stability of the product are also enhanced.

Owner:常州普格纳能源材料有限公司

Method for smelting low-grade tungsten and molybdenum ore and method for recycling phosphorus simultaneously during smelting of low-grade tungsten and molybdenum ore

ActiveCN107267781AStrong reductionImprove reduction efficiencyPhosphorus compoundsReduced propertiesBall mill

The invention discloses a method for smelting low-grade tungsten and molybdenum ore and a method for recycling phosphorus simultaneously during smelting of the low-grade tungsten and molybdenum ore and belongs to the field of resourceful utilization of the low-grade tungsten and molybdenum ore. The method for smelting the low-grade tungsten and molybdenum ore specifically includes the steps that (1) ore powder pre-treatment is performed, specifically, ore powder is added into a ball mill for ball milling; (2) mixing and pelletizing are performed, specifically, a composite reducing agent is added into the ore powder for dry mixing, a bonder is added into a mixture obtained after uniform mixing is finished, and tungsten and molybdenum ore pellets are prepared on a disc pelletizing machine; and (3) smelting of the tungsten and molybdenum ore is performed, specifically, the tungsten and molybdenum ore pellets are dried in a drying oven and then added into a vacuum furnace for reducing smelting, and the smelting temperature ranges from 1300 DEG C to 1500 DEG C. By means of the method for smelting the low-grade tungsten and molybdenum ore, silicon powder wrapping the surface of modified silicon carbide of the composite reducing agent is good in reaction property and can rapidly intervene in the reaction under promotion of modified quartz, CO with the reducing property can be generated during reaction of the modified silicon carbide, and the reducing efficiency of the low-grade tungsten and molybdenum ore can be improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

A method for efficiently synthesizing high-purity molybdenum disulfide

ActiveCN110357162BWell mixedMix for a certain time evenlyMolybdenum sulfidesMicrowave tubeThermal insulation

The invention discloses a high-efficiency method for synthesizing high-purity molybdenum disulfide, specifically: firstly, putting molybdenum trioxide powder or molybdenum dioxide powder and sulfur powder into a pulverizer, mixing and pulverizing to obtain a mixed raw material; then mixing the raw material Put it in a crucible, put it in the insulation sleeve of the microwave tube atmosphere furnace, put the insulation sleeve into the quartz tube, seal both ends of the microwave tube atmosphere furnace, pass in argon gas, turn on the microwave heating, keep warm, and cool to room temperature , you can get high-purity molybdenum disulfide. The present invention uses molybdenum trioxide or molybdenum dioxide and sulfur as raw materials, microwave heating, and direct vulcanization method to synthesize high-purity molybdenum disulfide. One-time synthesis does not require high pressure, thiolation and decomposition, shortens the process flow, and improves production efficiency; The molybdenum disulfide obtained by the method has high purity and fine particle size, and is suitable for large-scale production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com