Cyclopentanol green synthetic method

A technology for green synthesis and cyclopentanone, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of less side reactions, corrosion, and low energy consumption, so as to increase yield and reduce The effect of scrap rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

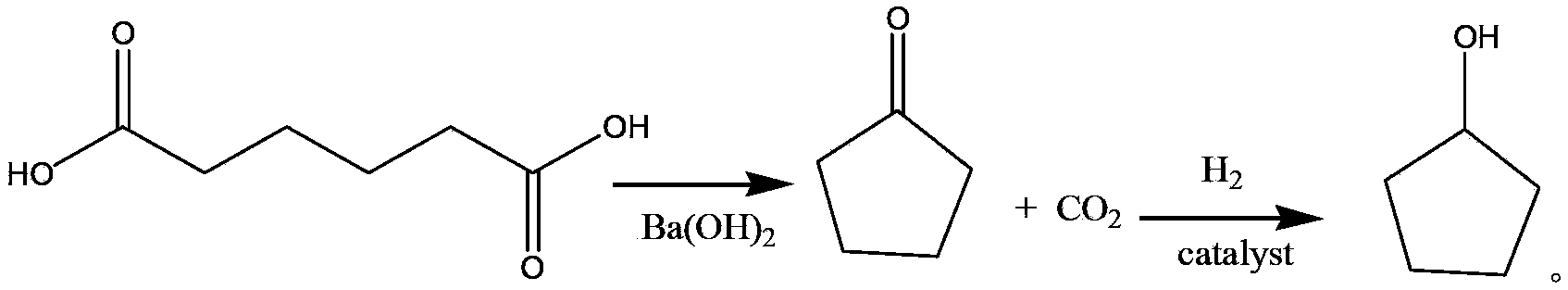

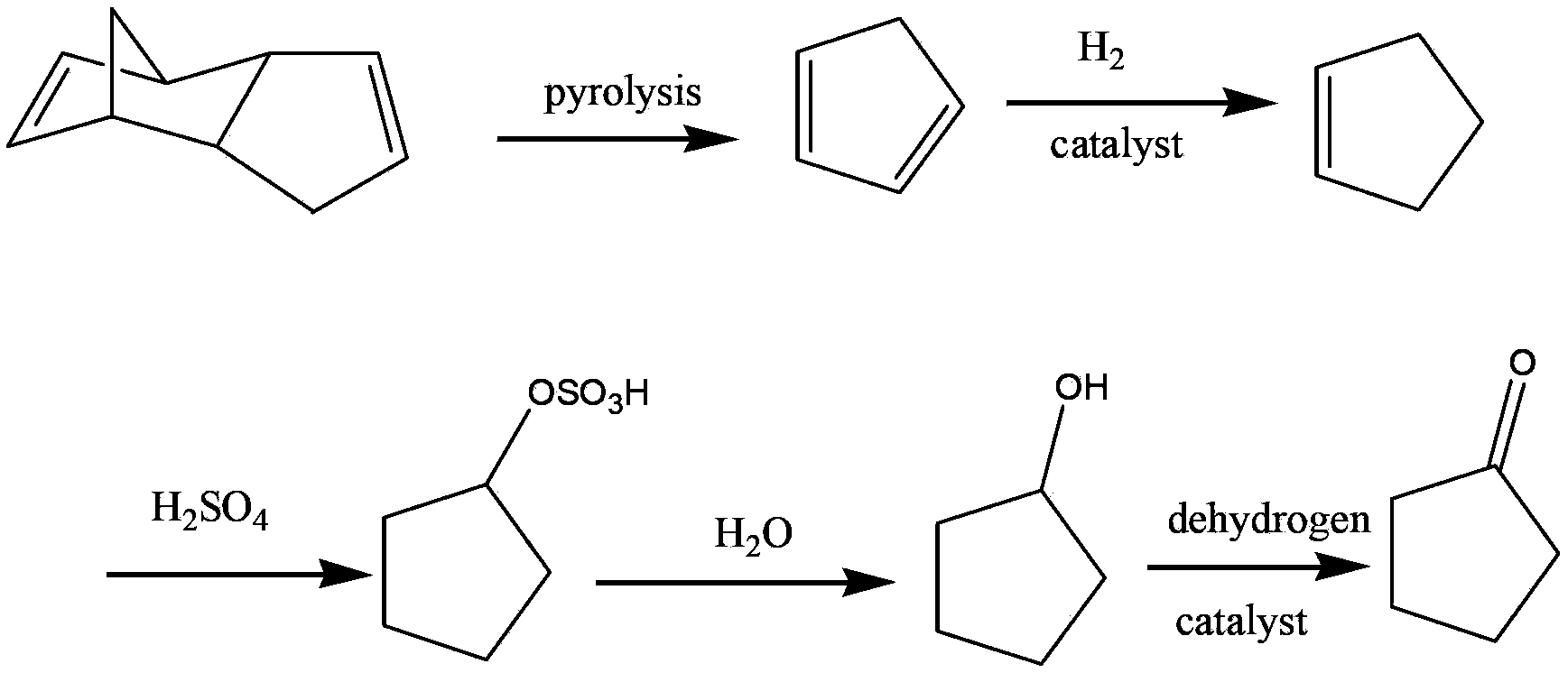

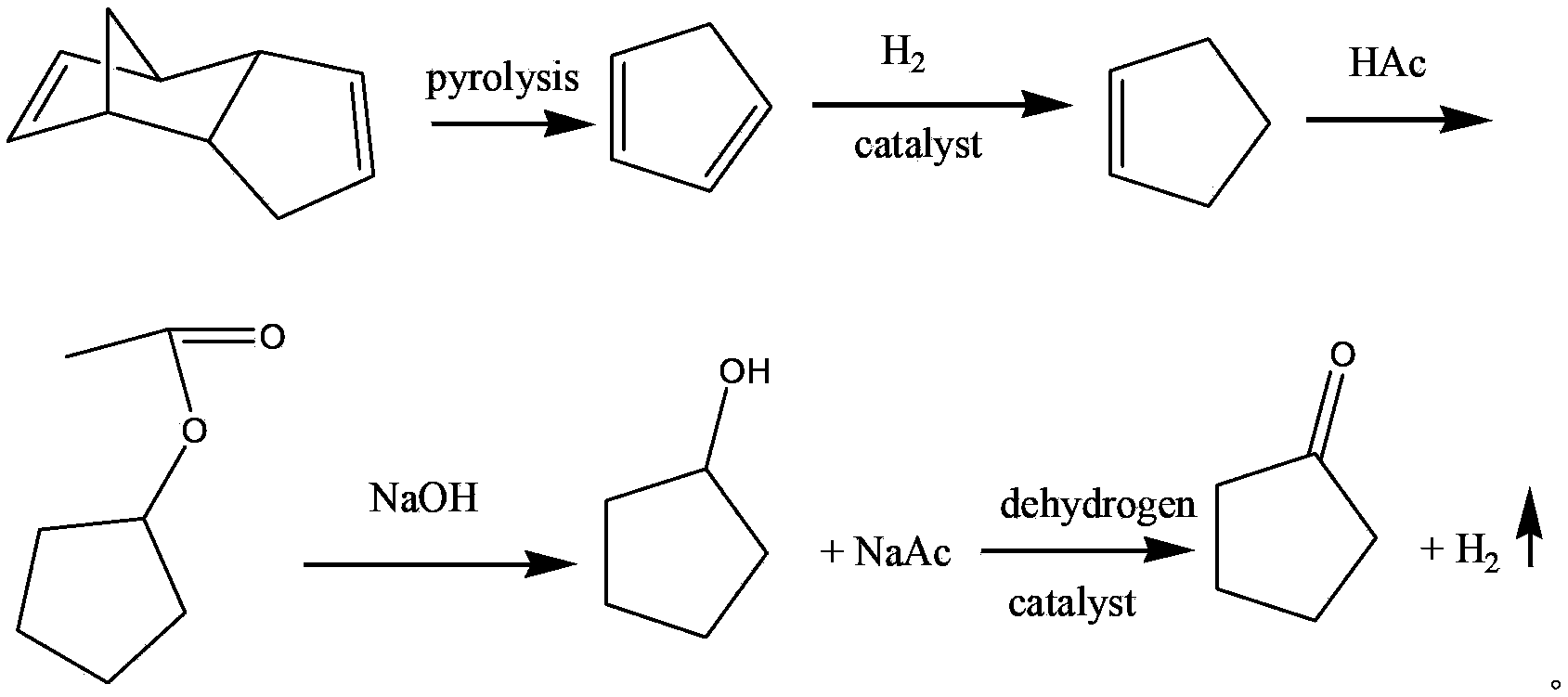

Method used

Image

Examples

Embodiment 1

[0028]A green synthesis method of cyclopentanone in this embodiment is characterized in that it includes the following steps: 1) Using dicyclopentadiene, a by-product in the process of producing ethylene from petroleum cracking, as a raw material, high-temperature cracking and rapid separation and cooling to obtain cyclopentadiene ; 2) Cyclopentadiene is prepared by selective hydrogenation under the action of the first catalyst, adding 4,5-dimethyl-1,3-dioxole as an auxiliary agent with a mass fraction of 0.8% cyclopentene; 3) then cyclopentene and acetic esterification reaction to obtain cyclopentyl acetate; 4) followed by the reaction of cyclopentyl acetate and sodium hydroxide to generate cyclopentyl alcohol; 5) using constant temperature crystallization technology, high temperature acetic acid The sodium solution is continuously added to the crystallization tank with cyclopentanol, and under the action of the second catalyst, the crystals are separated by continuous centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com