An anti-corrosion and high-temperature resistant reaction device integrating reaction and separation

A reaction device and high-temperature-resistant technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., to achieve the effect of improving material conversion rate, benefiting engineering strengthening, and economical rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

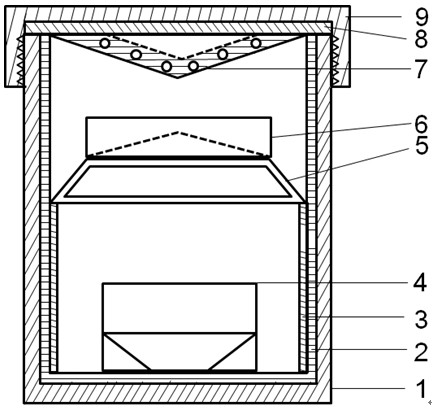

[0040] An anti-corrosion and high-temperature-resistant reaction device integrating reaction and separation, including a reaction kettle body 1, an anti-corrosion layer 2, a support 3, a reactant container 4, a support transition section 5, a separation aid box 6, a condensation cone 7, a sealing Pad 8, and reaction kettle cover 9, the reaction temperature in the device is about 250°C, and the pressure is about 4.0 MPa. A polytetrafluoroethylene lining is provided in the 316 stainless steel reaction kettle body 1 as an anti-corrosion layer 2; at the bottom Stack two polytetrafluoroethylene containers 4; place a porous transition section 5 on a polytetrafluoroethylene-coated steel support 3 to support a separation aid box 6 made of polytetrafluoroethylene; The sealing gasket 8 and the condensing cone 7 are integrated, and the reaction kettle cover 9 is provided with a thread and the thread of the reaction kettle body to cooperate with the sealing gasket to achieve sealing. The w...

Embodiment 2

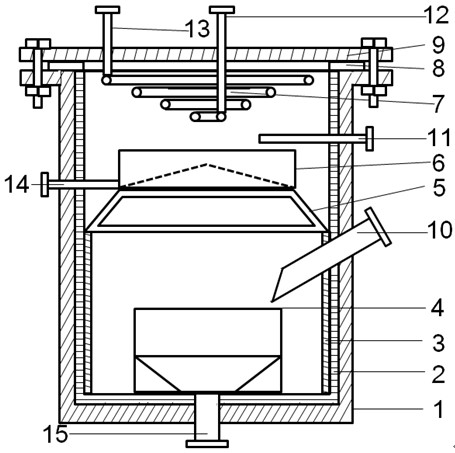

[0042] An anti-corrosion and high-temperature-resistant reaction device integrating reaction and separation, which consists of a reaction kettle body 1, an anti-corrosion layer 2, a support 3, a reactant container 4, a support transition section 5, a separation aid box 6, a condensation cone 7, a sealing Pad 8, Reactor cover 9, Reactant feed pipe and flange 10, Auxiliary input pipe and flange 11, Coolant inlet pipe and flange 12, Coolant outlet pipe and flange 13, Auxiliary vent Pipe and flange 14, and product outlet pipe and flange 15; the reaction temperature in the kettle does not exceed 800 ° C, the pressure does not exceed 6.0 MPa, and a tantalum liner is set in the 316 stainless steel reaction kettle body 1 as an anti-corrosion layer 2; A tantalum container 4 is placed at the bottom of the device; a tantalum porous transition section 5 is placed on the tantalum support 3 to support a gold-plated Hastelloy C alloy fetal separation aid box 6; a tantalum ellipsoidal head is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com