A composite reducing agent for smelting low-grade tungsten-molybdenum ore and its smelting method

A low-grade tungsten-molybdenum ore technology, which is applied in the field of compound reducing agent for smelting low-grade tungsten-molybdenum ore and its smelting field, can solve the problems of poor utilization effect of low-grade tungsten-molybdenum ore, improve reduction efficiency, increase reduction capacity, The effect of reducing reaction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

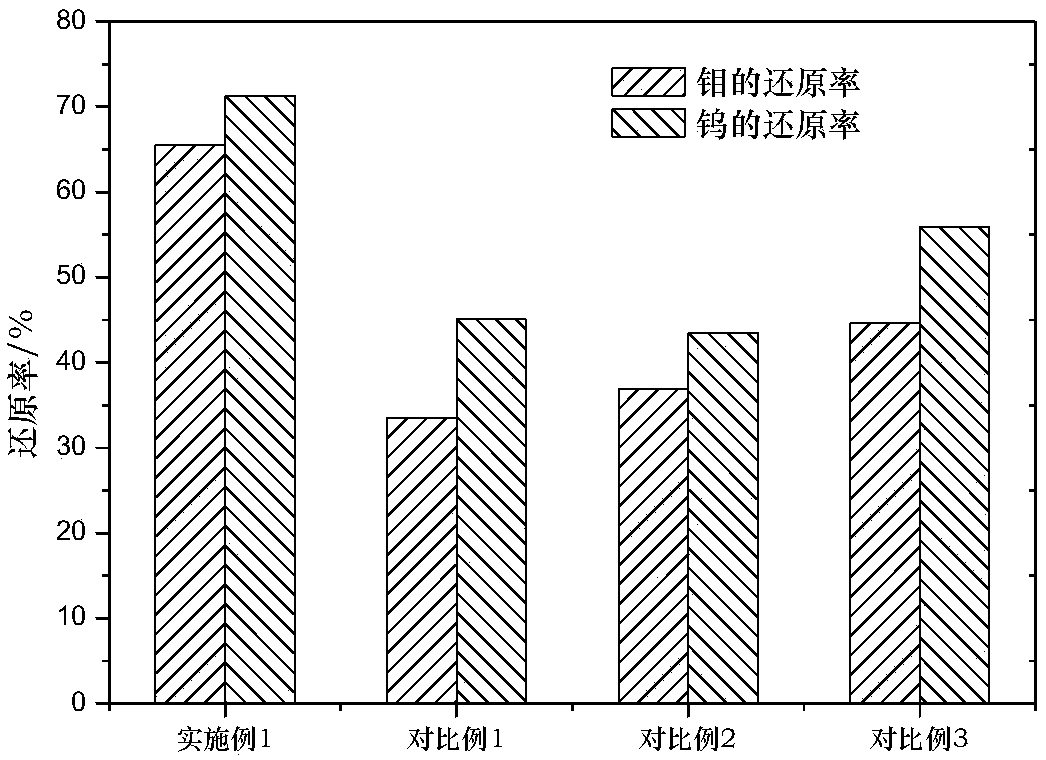

Embodiment 1

[0029] 本发明的一种用于冶炼低品位钨钼矿的复合还原剂,包括改性碳化硅、改性石英和添加剂;所述的改性碳化硅为碳化硅粉与硅粉的的混合物,所述改性石英为在表面包覆有包覆组分的石英,该包覆组分为沥青;包覆组分和石英混在50-90℃温度下混合搅拌得到改性石英,其中改性石英的石英与包覆组分的质量比为6-7:1,本实施例为7:1。

[0030] 即先将石英加入反应釜中升温至40-50℃,并保温20min,再升温至50-90℃,本实施例为60℃;再将沥青粉末加入反应釜中,并将沥青粉末包覆于石英表面得到改性石英,并保温10min。

[0031] 改性碳化硅在碳化硅粉和硅粉中加入高岭土,加水混合后得到改性碳化硅;所述碳化硅粉和硅粉的质量之比为2~4:1,本实施例为3:1;高岭土的-325目为90%,即小于325目的颗粒大于90%,本实施例为91%。改性碳化硅的具体制备步骤为:将碳化硅粉和硅粉中加入高岭土在烘箱中烘干,先向碳化硅粉中加入高岭土并在搅拌机中搅拌均匀,而后一边向搅拌机雾化的水溶液,一边向搅拌机中加入硅粉,加完之后继续混合均匀形成颗粒状,并加热烘干得到改性碳化硅。其中高岭土为中低温热液蚀变残余型高岭土,也称之为苏州土;本实施例的氧化铝含量为36%,二氧化硅48%。

[0032] 改性碳化硅与改性石英的质量之比为α,α取值为0.7~1.5,本实施例去α=1;所述的添加剂占改性碳化硅和改性石英总质量的1~4%。

[0033] 本发明的添加剂包括焦粉,所述焦粉在球磨机中进行球磨,在球磨机中球磨后焦粉的颗粒小于200目。

[0034] A kind of preparation method of composite reducing agent of the present invention, concrete steps are:

[0035] S1: Preparation of modified silicon carbide

[0036] Add kaolin to silicon carbide powder and stir evenly in a mixer, then add silicon powder to the mixer, and mix to obtain modified silicon carbi...

Embodiment 2

[0077] The basic content of this example is the same as that of Example 1, except that the additives also include plastic powder and biomass, and the mass ratio of coke powder, plastic powder and biomass is 5:2:2. Soak the biomass and biomass in the alkaline solution of NaOH and NaCl at 60-80°C, and dry after soaking; after drying, stir the coke powder, plastic powder and biomass at 150-250°C Mixing, so that the plastic powder and biomass and coke powder adhere together, wherein the particles of the plastic powder and biomass are less than 250 mesh. The plastic powder is any one or a mixture of polyethylene, polyoxymethylene, polyamide, polypropylene, polystyrene, polycarbonate, polymethyl methacrylate and polyester. The plastic powder in this embodiment is polypropylene, polystyrene, polycarbonate; the mass ratio of polypropylene, polystyrene, polycarbonate is: 3:1:2. CO and H produced by decomposition of biomass and plastic powder in additives 2 Other reducing gases such a...

Embodiment 3

[0079] The basic content of this embodiment is the same as that of Example 1, except that the reducing agent also includes aluminum powder, and the aluminum powder-300 mesh is 80%, that is, the particles smaller than 300 in the aluminum powder account for 80% ; The aluminum powder is externally prepared, and the aluminum powder accounts for 1.2% of the total mass of modified silicon carbide and modified quartz. The temperature is raised to 1300-1500°C for smelting. In this embodiment, it is 1380°C. The smelting time is 1-3h. The embodiment is 3h, and the reduction process is completed. After cooling to room temperature and crushing, detection and analysis (W, Mo, P content). Among them, the reduction rate of tungsten is 73.1%, and that of molybdenum is 66.9%.

[0080] During the reduction process, the aluminum powder in the composite reducing agent releases a large amount of heat in the process of reducing the oxide, which promotes the fusion of the composite reducing agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com