Preparation method for cobalt-modified porous charcoal catalyst for demercuration

A biochar and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as uneven dispersion of active ingredients, and achieve simple and convenient synthesis methods, large specific surface area, and source broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

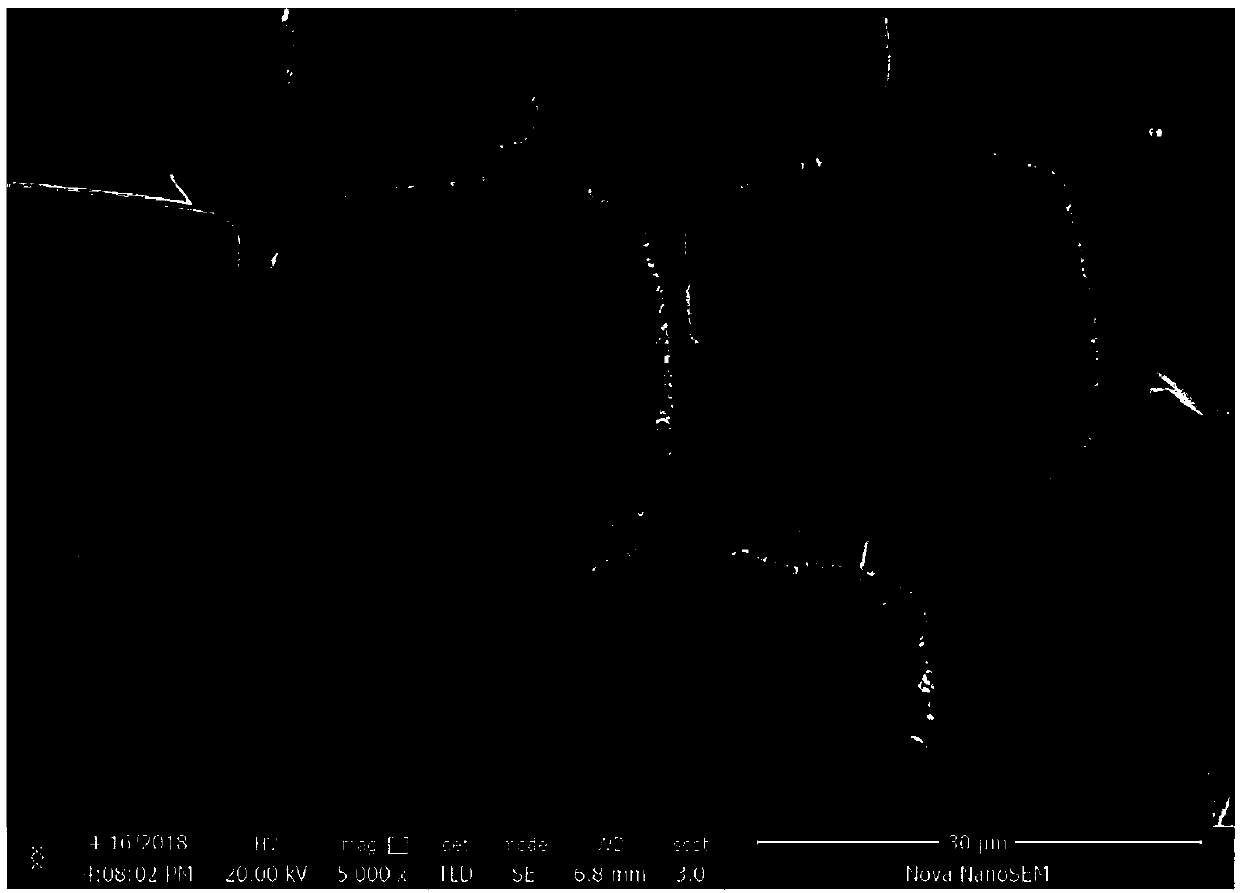

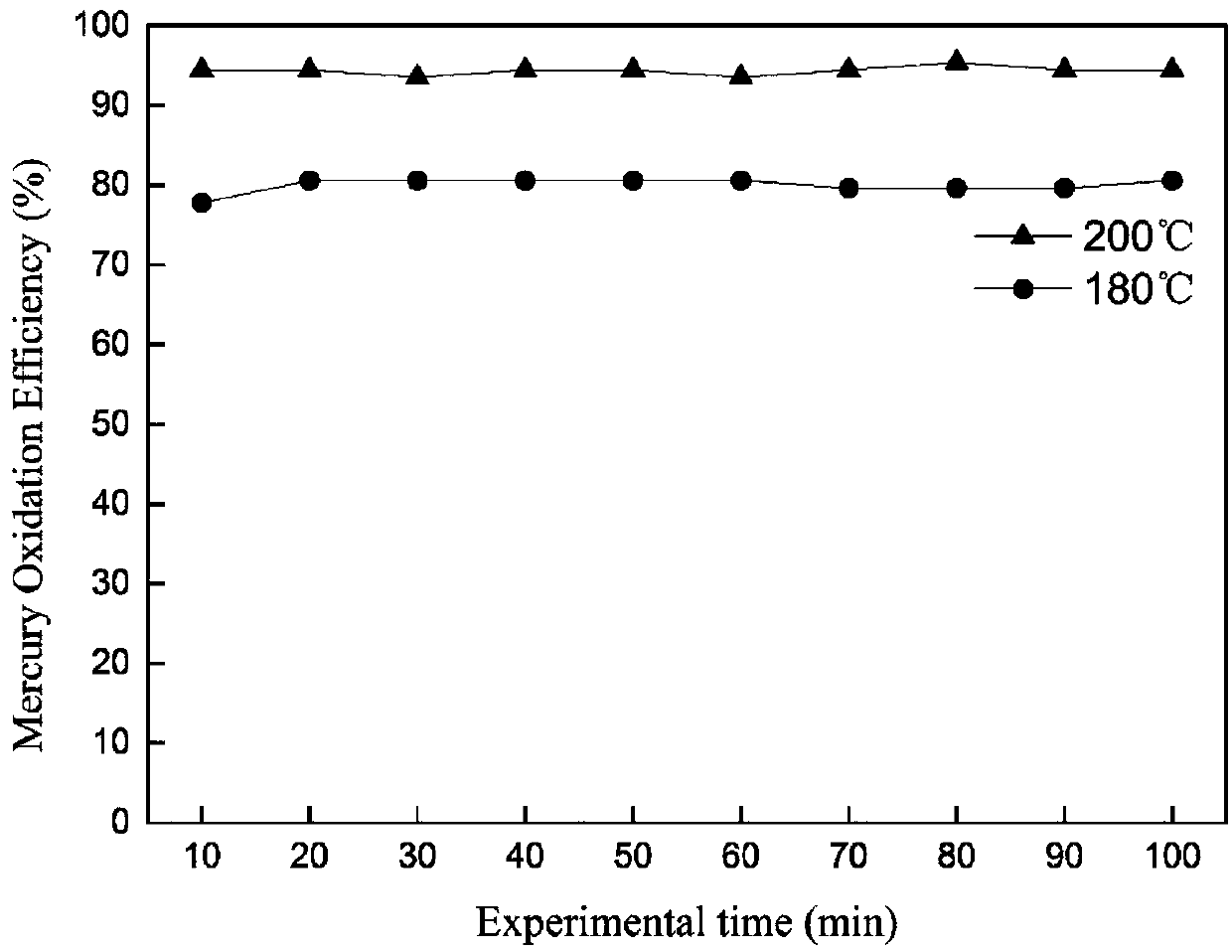

Image

Examples

Embodiment 1

[0025]The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 1.8325g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitra...

Embodiment 2

[0027] The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 2.75g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitrat...

Embodiment 3

[0029] The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 3.655g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com