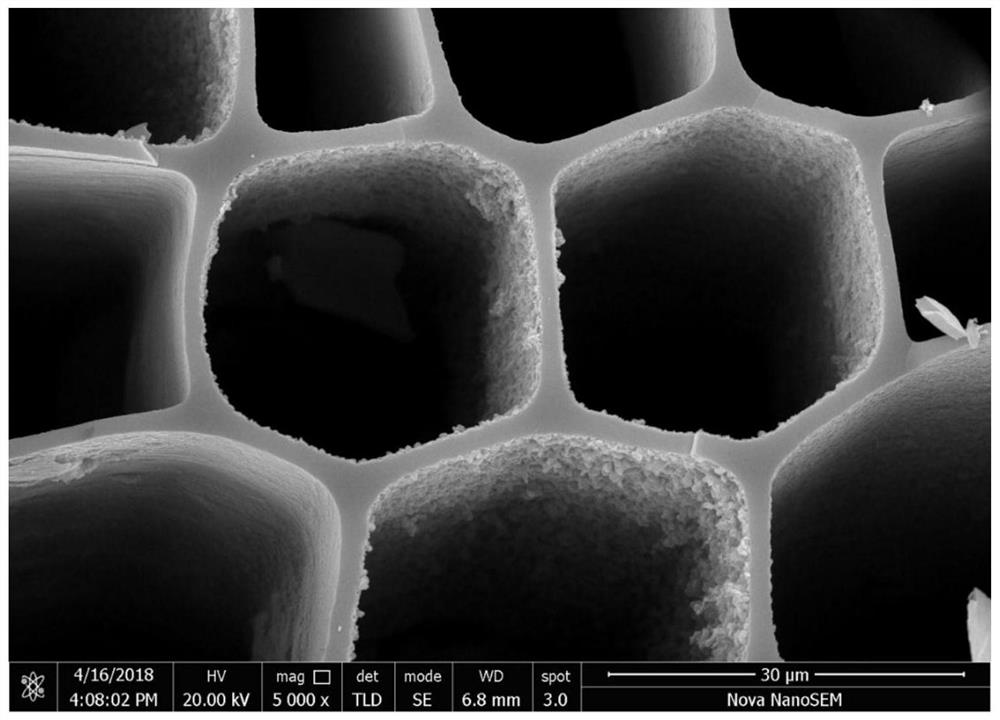

A preparation method of cobalt-modified porous biochar catalyst for mercury removal

A biochar and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as uneven dispersion of active components, and achieve a simple and convenient synthesis method, mild reaction conditions, huge The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

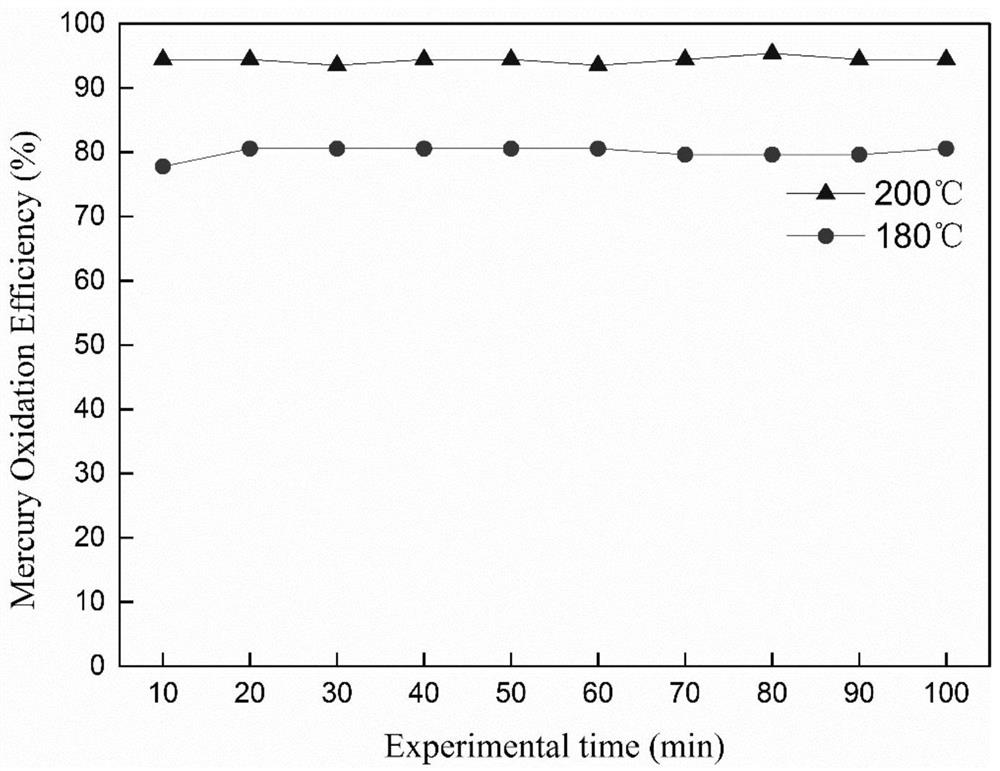

Embodiment 1

[0025]The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 1.8325g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitra...

Embodiment 2

[0027] The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 2.75g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitrat...

Embodiment 3

[0029] The raw wood was cut into small pieces of 1cm×1cm, treated with magnetic stirring in deionized water at 90°C for 6h to remove debris and impurities on the surface, and dried in an oven at 100°C for 24h. Take 5.3115g cobalt acetate and 3.655g ethanolamine to prepare 0.3mol / L cobalt acetate solution (solution A) and 0.3mol / L ethanolamine solution (solution B) respectively; take 30mL solution A and 30mL solution B in a beaker, add etc. A certain amount of absolute ethanol was mixed, and the resulting mixed solution was stirred in a water bath at 60° C. for 2 hours to obtain a uniform colloidal solution. Take 1 g of pretreated wood strip slices on a petri dish, use a syringe to take 2 mL of colloid solution and evenly coat the surface of wood strips, treat it in a vacuum oven at 30 °C for 1 h, and then dry it in an oven at 90 °C for 1.5 h. The process cycle is performed three times. Get 1.4604g cobalt nitrate and 0.7g urotropine, respectively prepare 0.05mol / L cobalt nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com