Preparation method of special nitrogen-doped molded active carbon for catalyst carrier

A technology for forming activated carbon and catalyst carrier, which is applied in the preparation of organic compounds, preparation of amino compounds, chemical instruments and methods, etc. It can solve the problems of large specific surface area and high mechanical strength, and achieve high product yield, high mechanical strength, and economical The effect of benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

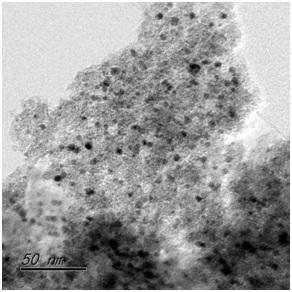

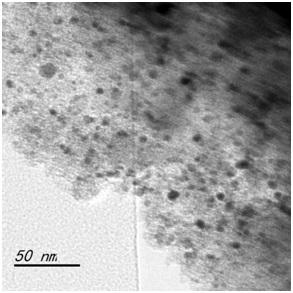

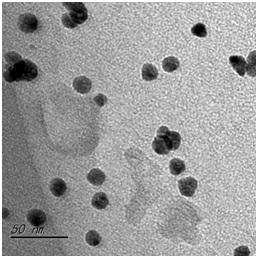

[0027] Take 50 grams of dried Chinese fir chips, put them at 600 o C reaction conditions and NH 3 React for 4 hours and cool to obtain a nitrogen-doped biochar material. These nitrogen-doped biochar materials are pulverized, sieved, added with 100 grams of phenolic resin, kneaded, and extruded into a columnar shaped carbon precursor by an extruder. These shaped carbon precursors were then heated at 120 o C dried overnight, then placed in tube furnace 600 o C carbonization for 2 hours, and finally heated up to 900 o C, activated by passing water vapor for 1 hour, and obtained nitrogen-doped shaped activated carbon. The obtained carbon material has a particle size of Ф3 mm and a nitrogen content of 2.0%. The specific surface area is 1050 cm 2 / g, the average pore size is 2 nm, and the mechanical strength is > 95%.

[0028] With the nitrogen-doped formed carbon obtained above as the catalyst carrier, K 2 PdCl 6 The solution is the precursor, according to the carrier and ...

Embodiment 2

[0030] Get 50 grams of dried fir chips, add 10 grams of melamine and mix them at 600 o The reaction was carried out under the condition of C for 2 hours, and cooled to obtain a nitrogen-doped biochar material. These nitrogen-doped biochar materials are pulverized, sieved, added with 100 grams of phenolic resin, kneaded, and extruded into a columnar shaped carbon precursor by an extruder. These shaped carbon precursors were then heated at 120 o C dried overnight, then placed in tube furnace 600 o C carbonization for 2 hours, and finally heated up to 900 o C, activated by passing water vapor for 1 hour, and obtained nitrogen-doped shaped activated carbon. The particle size of the obtained carbon material is Ф3mm, and the nitrogen content is 3.0%. The specific surface area is 900cm 2 / g, mechanical strength> 95%.

[0031] With the nitrogen-doped formed carbon obtained above as the catalyst carrier, K 2 PdCl 6 The solution is the precursor, according to the carrier and K ...

Embodiment 3

[0033] Take 50 grams of dried coconut shells as raw materials, at 800 o C reaction conditions and NH 3 React for 4 hours and cool to obtain a nitrogen-doped biochar material. These nitrogen-doped biochar materials are pulverized, sieved, added with 100 grams of phenolic resin, kneaded, and extruded into a columnar shaped carbon precursor by an extruder. These shaped carbon precursors were then heated at 120 o C dried overnight, then placed in tube furnace 600 o C carbonization for 2 hours, and finally heated up to 900 o C, activated by passing water vapor for 1 hour, and obtained nitrogen-doped shaped activated carbon. The particle size of the obtained carbon material is Ф3mm, and the nitrogen content is 1.5%. The specific surface area is 1120 cm 2 / g, the average pore size is 1.7nm, and the mechanical strength is > 95%.

[0034] Using the nitrogen-doped shaped carbon obtained above as a catalyst carrier, H 2 PtCl 6 The solution is the precursor, according to the carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com