Preparation method of phosphate anode material

A positive electrode material and phosphate technology, which is applied in the field of preparation of phosphate-based positive electrode materials, can solve problems such as large resistance, reduced product performance, and instability, and achieve the effects of improving discharge performance, reducing reaction resistance, and uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mg 3 (PO 4 ) 2 with MnPO 4 The precursor was mixed and ball-milled for 5 hours at a molar ratio of 0.1:1 to obtain a mixture;

[0023] (2) Pre-sintering the mixture in nitrogen at 400°C for 7 hours to obtain a pre-sintered product;

[0024] (3) The pre-sintered product was mixed with lithium carbonate and graphene for 5 hours, wherein the mol ratio of the pre-sintered product and lithium carbonate was 1: 1, and the addition of graphene was 10% of the pre-sintered product quality;

[0025] (4) sintering the ball-milled product in step (3) at 500° C. for 14 hours in nitrogen to obtain a sintered product;

[0026] (5) The sintered product is finely crushed and sieved to obtain magnesium-doped LiMnPO 4 Cathode material.

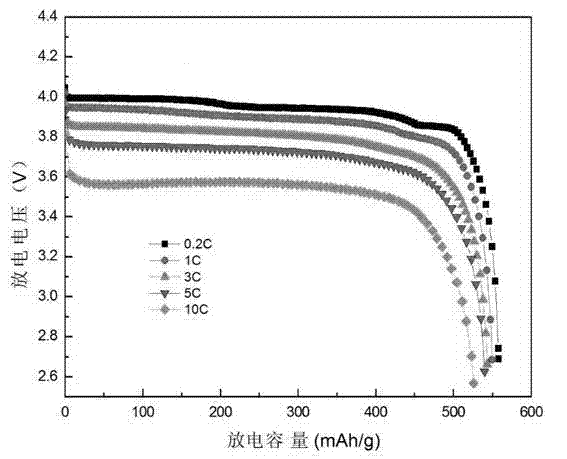

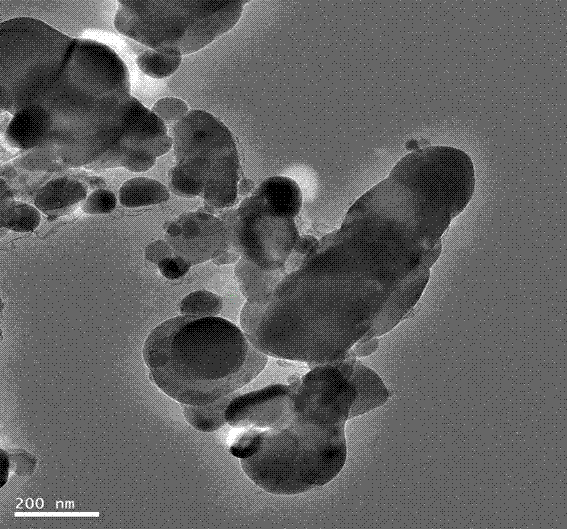

[0027] With the doping LiMnPO that embodiment 1 obtains 4 The discharge curve of the lithium-ion battery as the positive electrode material is as follows: figure 1 shown; the transmission electron microscope picture of the positive electrode ma...

Embodiment 2

[0029] (1) Nb 3 (PO 4 ) 5 with FePO 4 The precursor was mixed and ball-milled for 2 hours at a molar ratio of 0.01:1 to obtain a mixture;

[0030] (2) Pre-sintering the mixture in argon at 300° C. for 12 hours to obtain a pre-sintered product;

[0031] (3) The pre-sintered product was mixed with lithium hydroxide, glucose and sucrose and ball milled for 8 hours, wherein the molar ratio of the pre-sintered product to lithium hydroxide was 1: 0.95, and the amount of glucose and sucrose added was 1 / 2 of the pre-sintered product quality. 3%, wherein the mass ratio of glucose to sucrose is 1:1;

[0032] (4) sintering the ball-milled product in step (3) at 700° C. for 24 hours in argon to obtain a sintered product;

[0033] (5) The sintered product is finely crushed and sieved to obtain niobium-doped LiF e PO 4 Cathode material.

Embodiment 3

[0035] (1) Put Ti 3 (PO 4 ) 4 with CoPO 4 The precursor was mixed and ball-milled for 8 hours at a molar ratio of 0.05:1 to obtain a mixture;

[0036] (2) Pre-sintering the mixture in nitrogen at 450° C. for 2 hours to obtain a pre-sintered product;

[0037] (3) The pre-sintered product was mixed with lithium oxalate and superconducting carbon black and ball milled for 2 hours, wherein the mol ratio of the pre-sintered product to lithium oxalate was 1: 1.05, and the addition of superconducting carbon black was 1 / 2 of the pre-sintered product quality 15%;

[0038] (4) sintering the ball-milled product in step (3) at 900° C. for 4 hours in nitrogen to obtain a sintered product;

[0039] (5) The sintered product is finely crushed and sieved to obtain titanium-doped LiCoPO 4 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com