Spring operating mechanism buffer for circuit breaker

An operating mechanism, circuit breaker technology, applied in the direction of contact vibration/impact damping, etc., can solve the problems affecting the technical parameters of the circuit breaker opening process, and achieve improved reliability and stability, increased flow, and improved closing. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

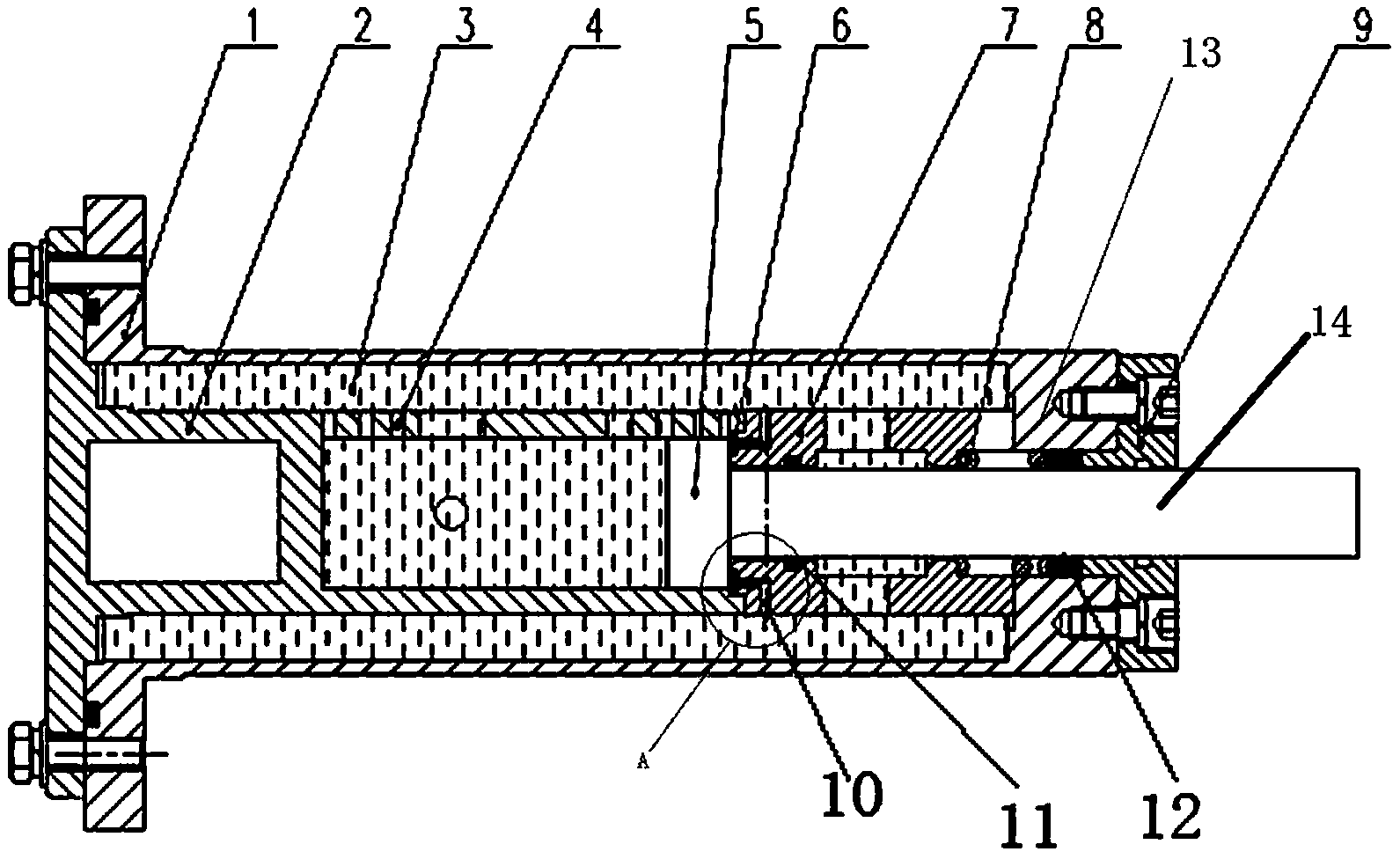

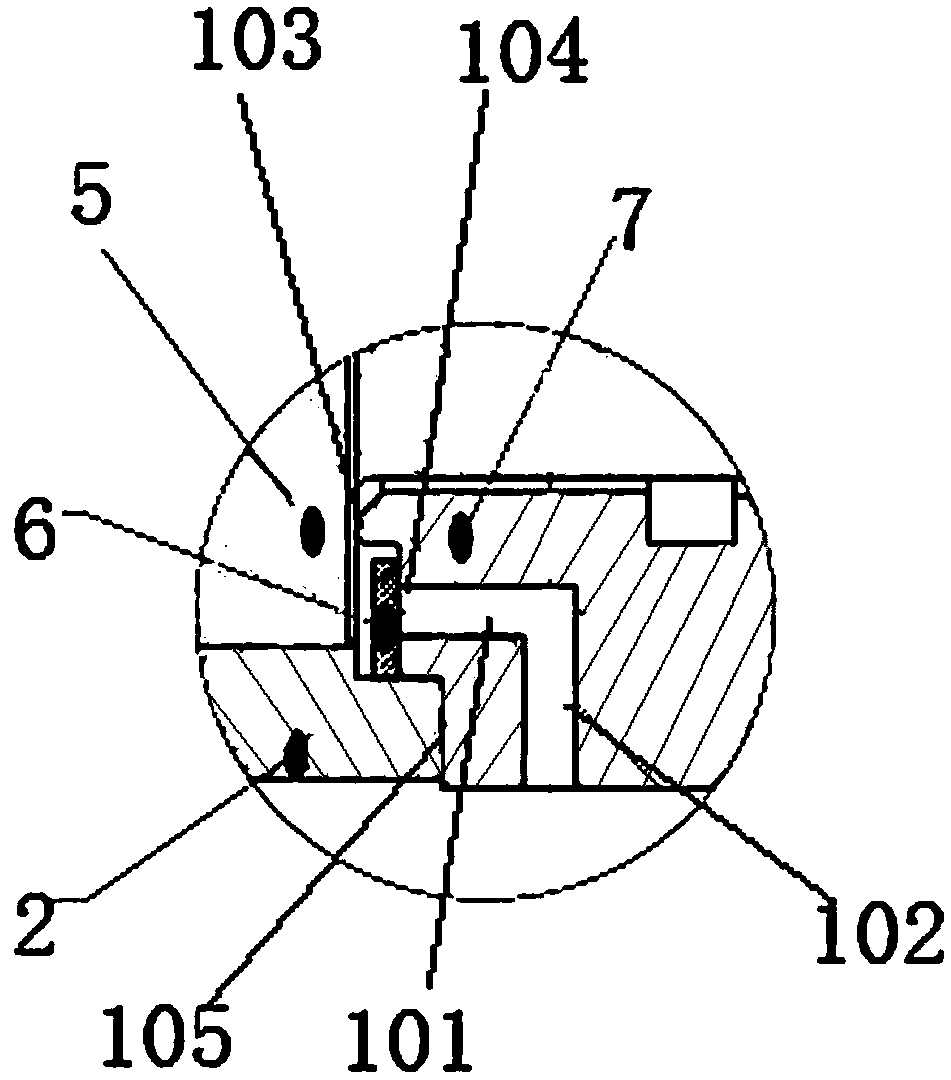

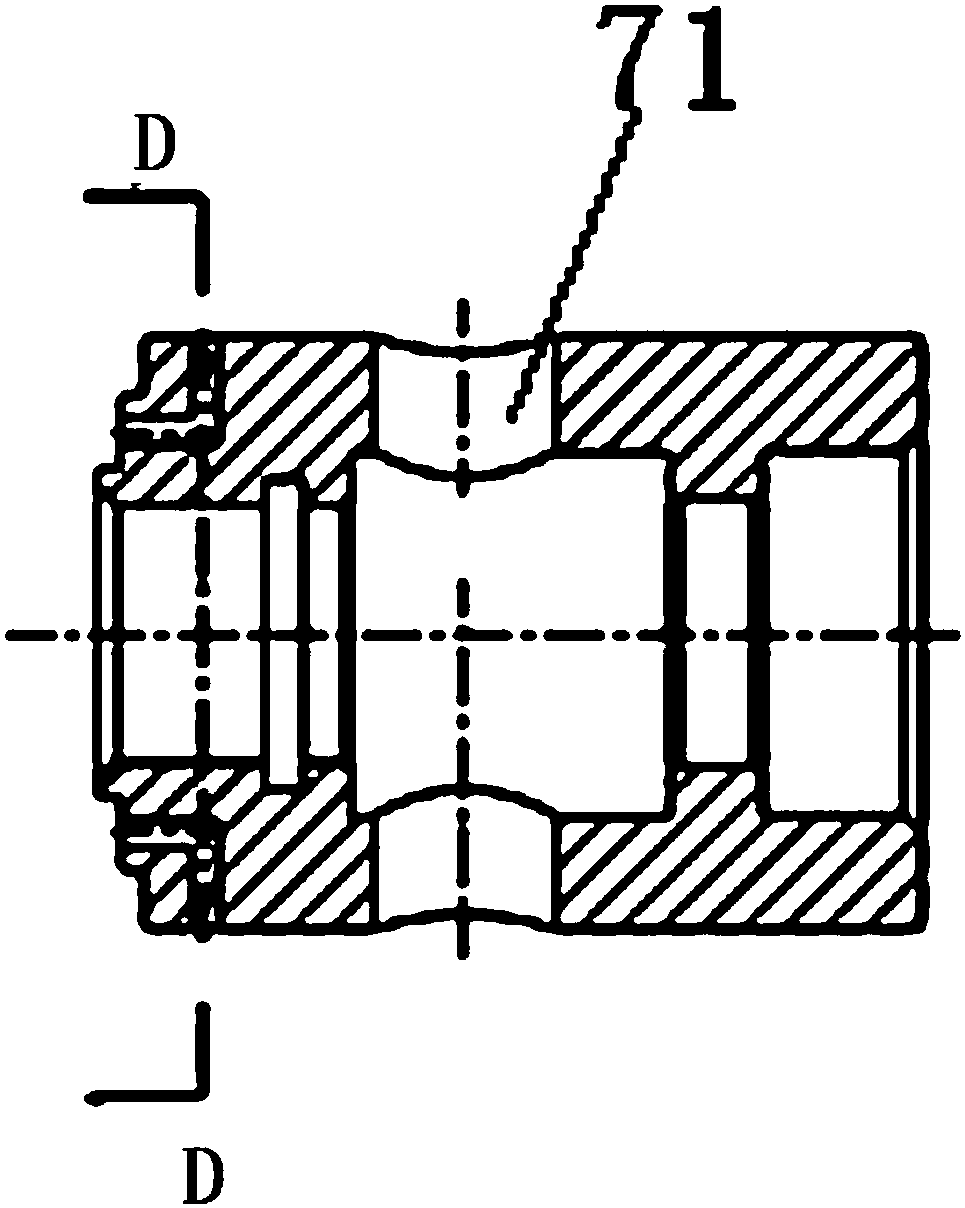

[0018] Such as Figure 1 to Figure 6 As shown, an embodiment of a spring operating mechanism buffer for a circuit breaker, the buffer in this embodiment includes an outer cylinder body 1 extending in the left and right direction, and an inner cylinder body 2 is sleeved in a coaxial gap in the outer cylinder body 1, The outer peripheral surface of the inner cylinder body 2 and the inner peripheral surface of the outer cylinder body 1 form a gap cavity, and the inner cylinder body 2 is provided with a flow hole 4 for communicating the inner cylinder body cavity and the gap cavity outside the inner cylinder body. A piston 5 for driving hydraulic oil 3 to flow between the inner cavity of the inner cylinder 2 and the clearance cavity outside the inner cylinder 2 is installed in the inner cylinder 2 for reciprocating movement. The left end of the outer cylinder body 1 is an open structure, and the left end of the inner cylinder body 2 has a left end cover 21 for blocking the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com