High-speed electromagnetic mechanism long in service life

An electromagnetic mechanism, long-life technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of easy burning of the upper and lower contacts, easy arcing of the upper and lower contacts, and high energy consumption of the electromagnetic mechanism, so as to prevent the upper and lower contacts. Point arc phenomenon, speed up closing speed, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

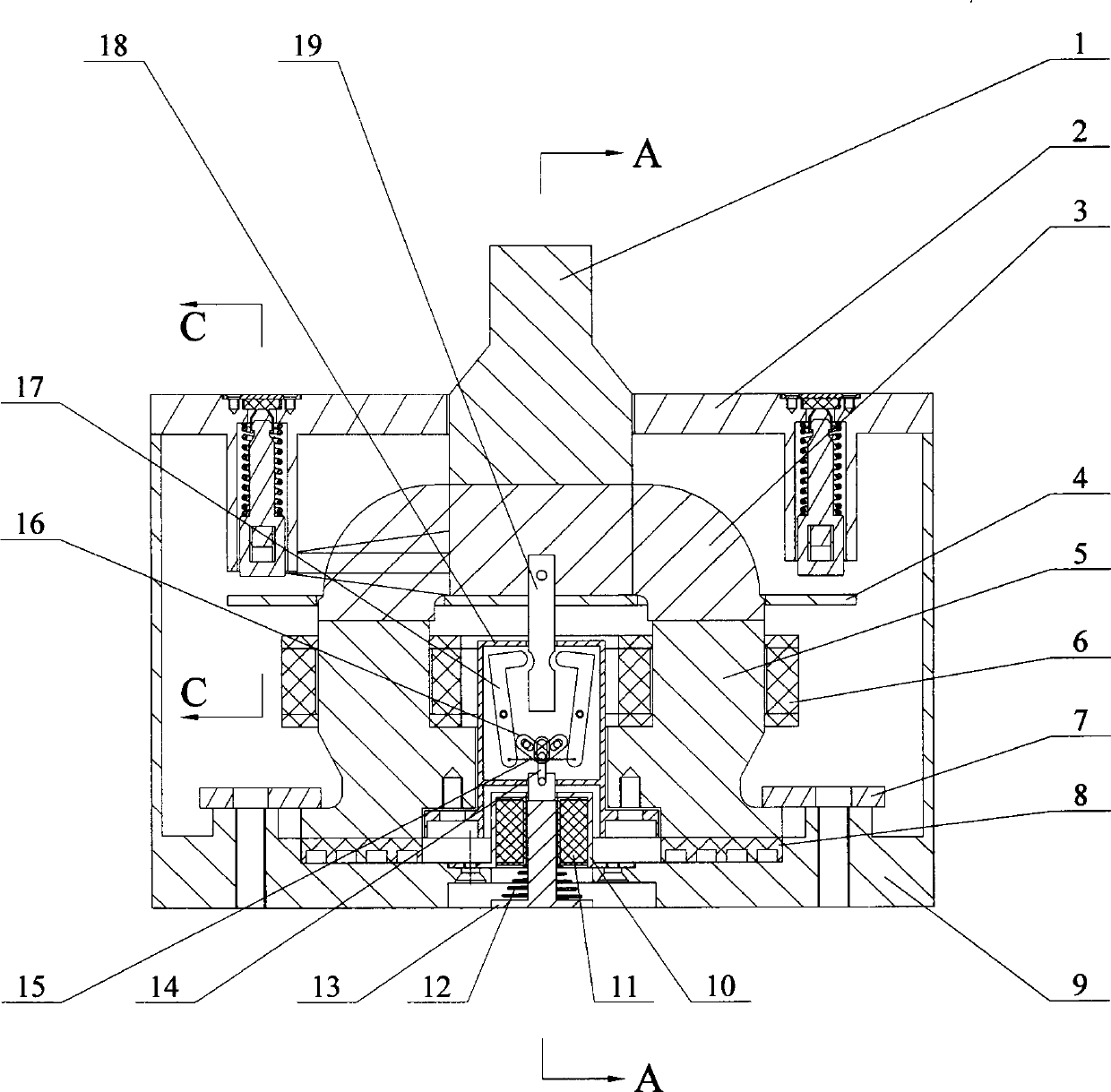

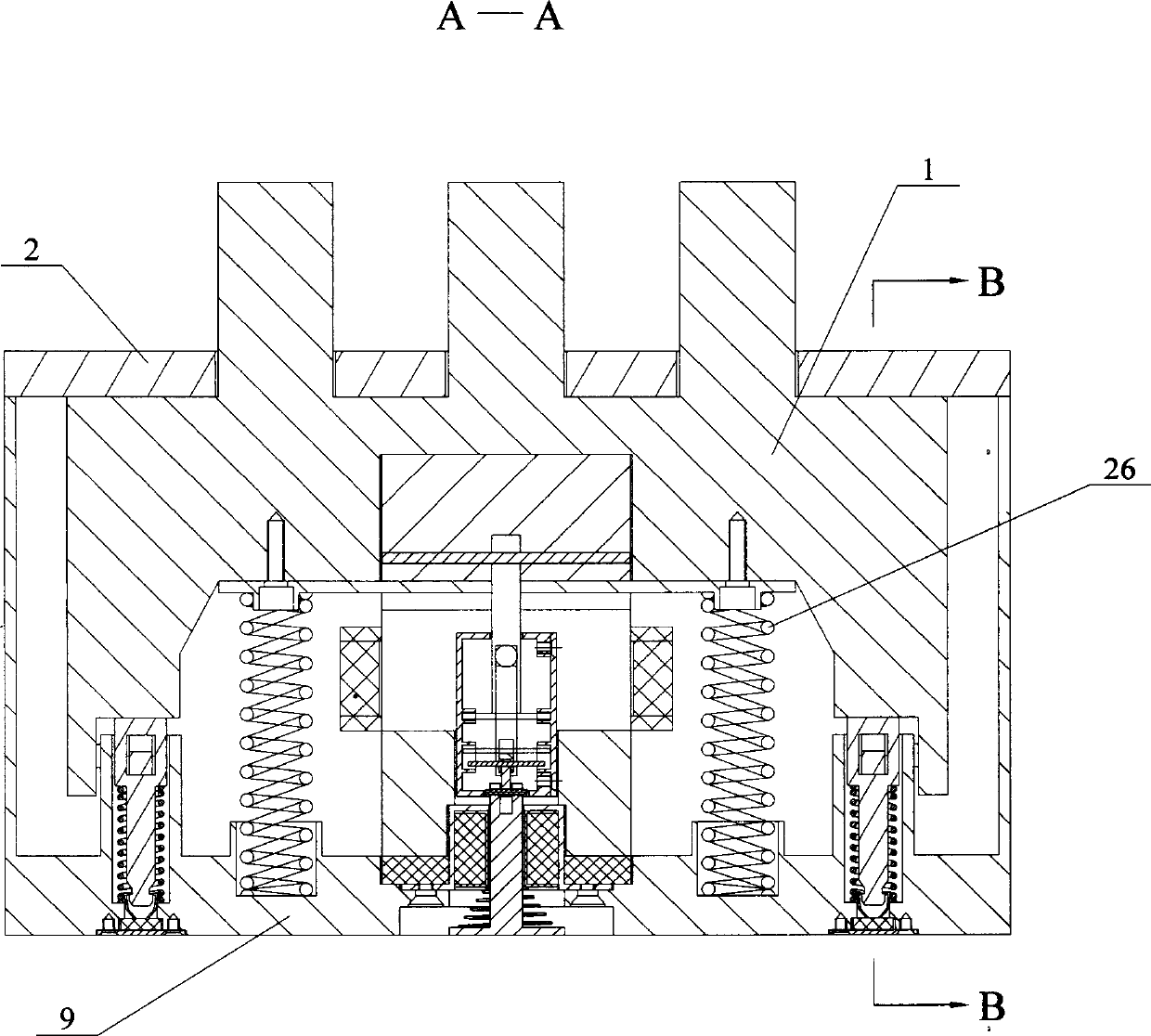

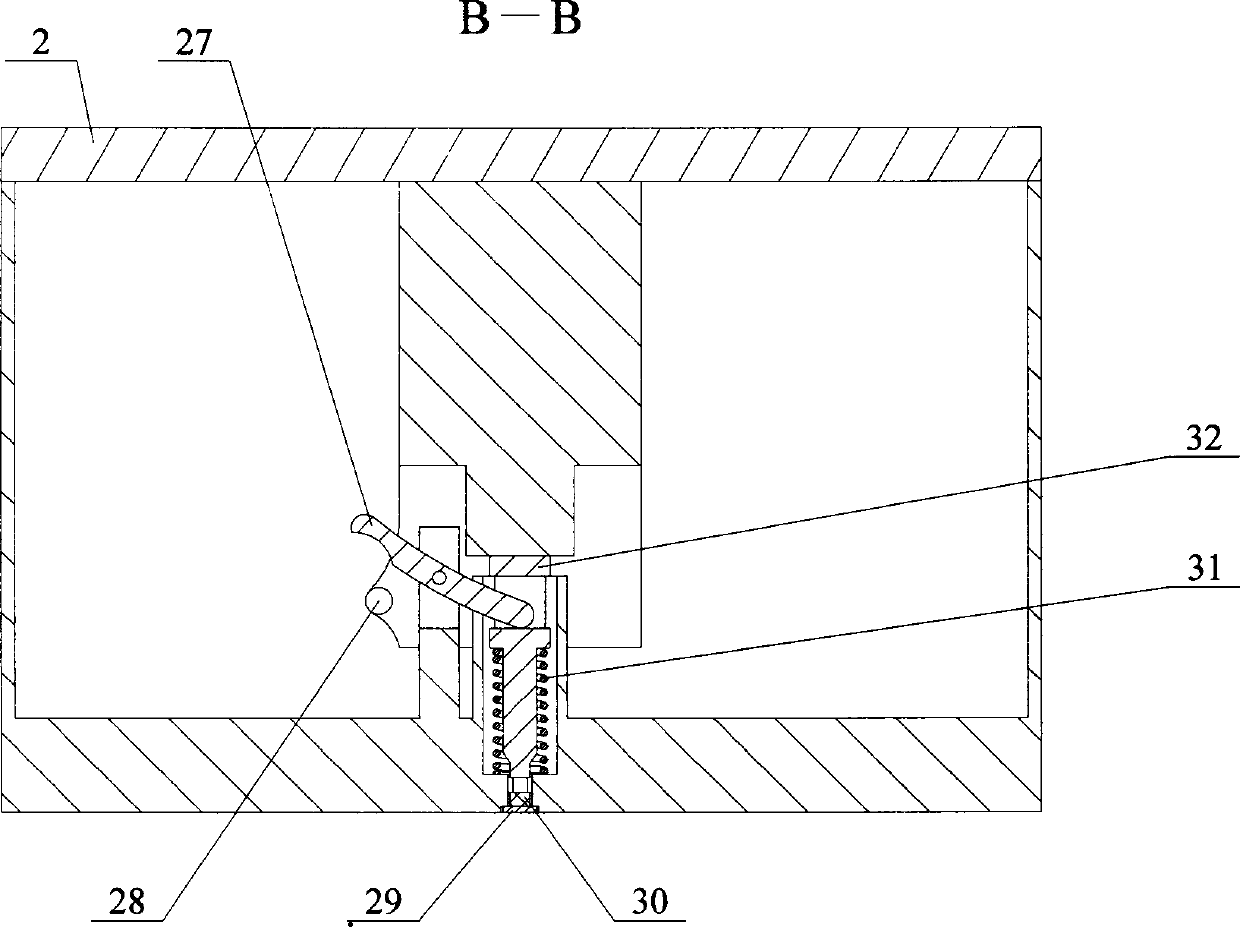

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0020] refer to Figure 1-Figure 4 , the specific embodiment adopts the following technical solutions: it includes a moving ram 1, an upper casing 2, a moving iron core 3, a moving iron core fixed mounting plate 4, a static iron core 5, a coil 6, a static iron core fixing plate 7, Shock absorbing pad 8, lower shell 9, retaining electromagnet shell 10, retaining electromagnet coil 11, retaining electromagnet return spring 12, retaining electromagnet action core rod 13, retaining electromagnet external movable connecting rod 14, reset tension spring 15. Sliding connecting rod 16, self-locking movable pull rod 17, self-lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com