Enzyme method for preparing gelatin

An enzymatic preparation and gelatin technology, applied in the field of enzymatic preparation of bone gelatin, can solve the problems of waste water discharge, unstable product quality and high extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

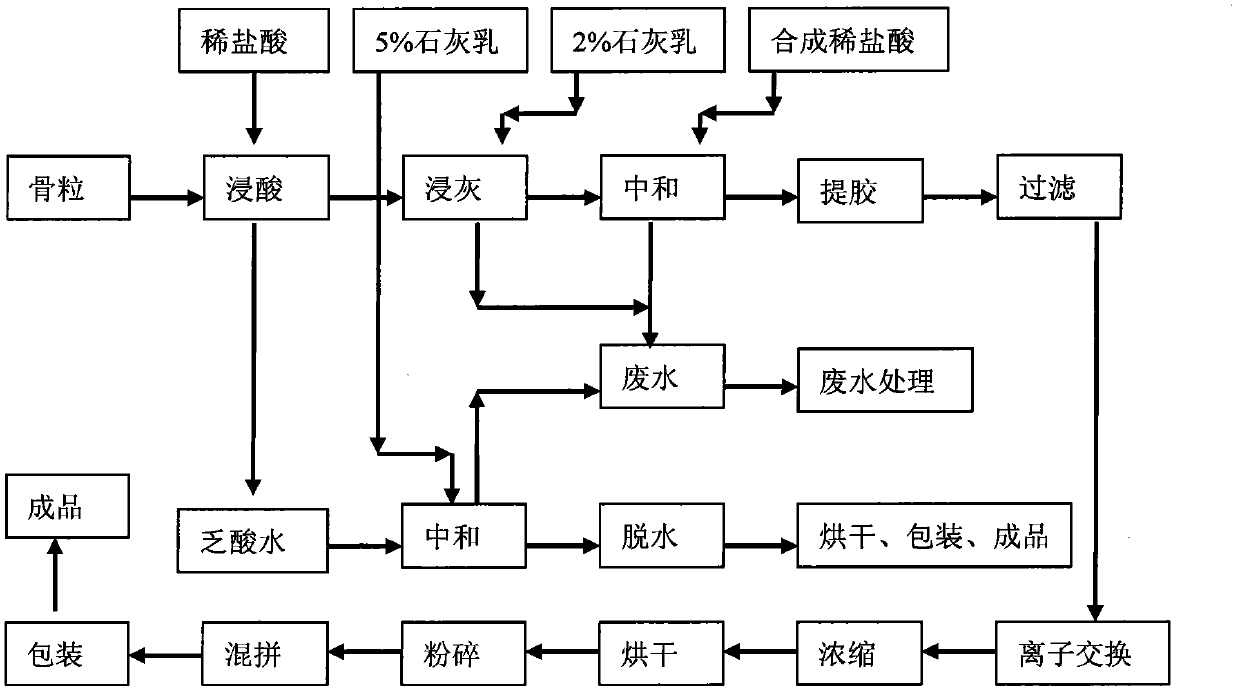

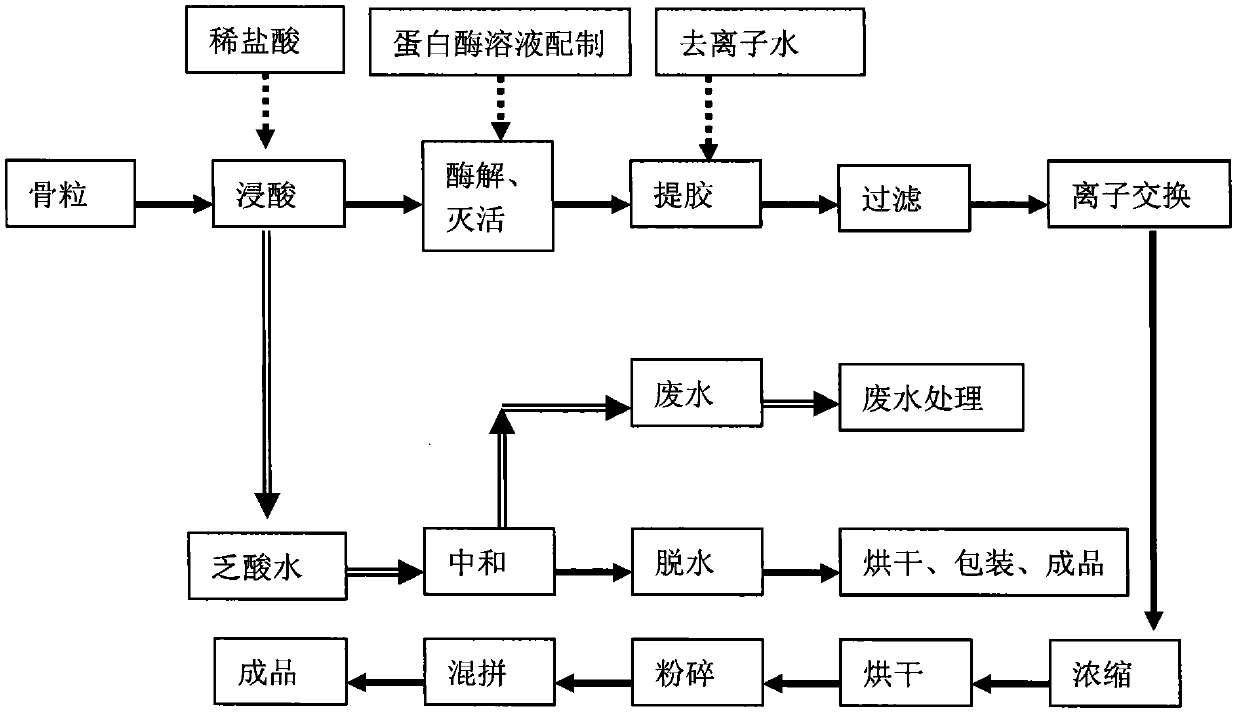

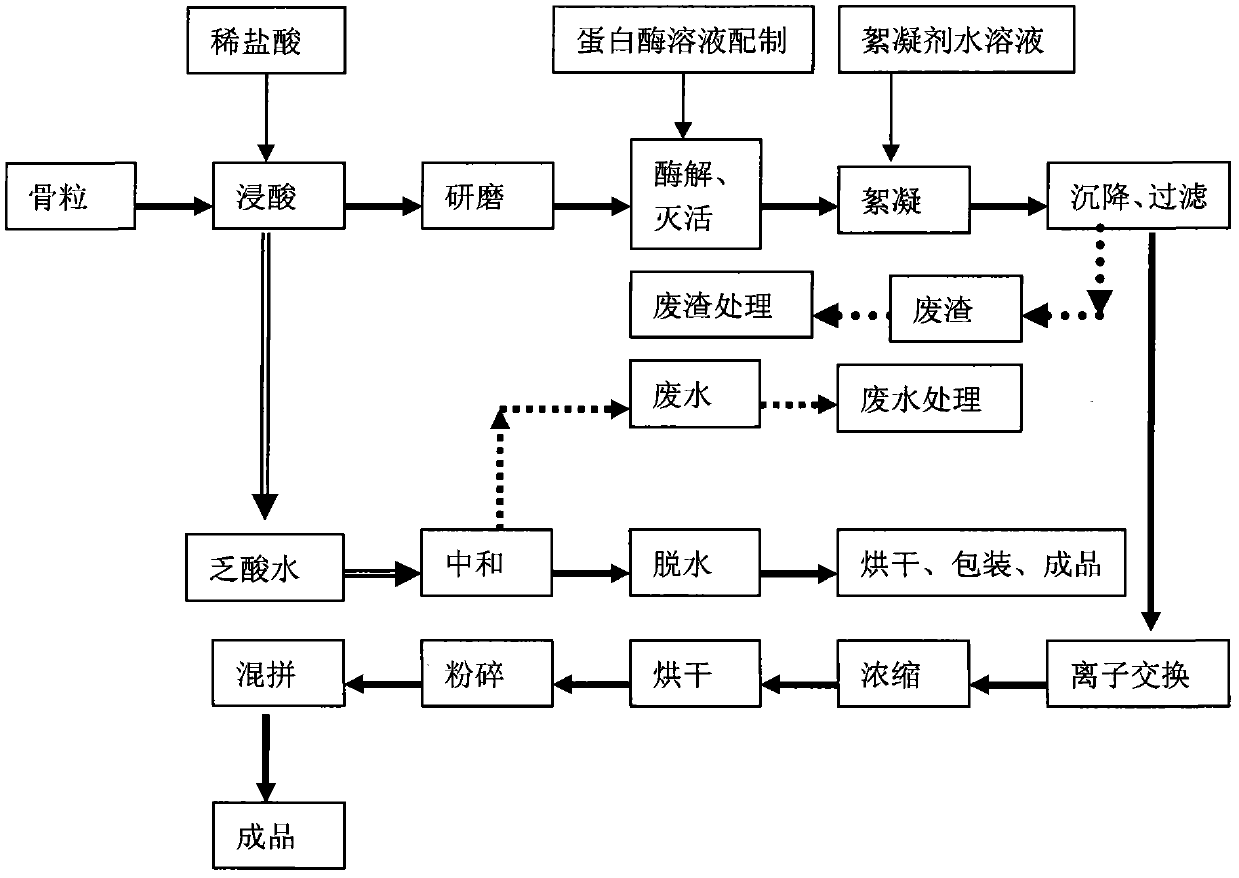

Method used

Image

Examples

Embodiment 1

[0116] Embodiment 1: enzymatic method gets bone gelatin

[0117] 1) Preparation and beating of bone meal:

[0118] Dry bone grains (water content≤10%, oil content≤4%), remove bone grains larger than 15cm, and then put the bone grains into a coarse grinder to grind them into bone powder with a particle size of ≤3mm (wherein bone powder with a particle size of ≤2mm accounts for 90%);

[0119] Add drinking tap water to the bone meal mixing tank G1 (self-designed, paddle agitator), add the measured bone powder into the bone meal mixing tank, and fully stir, according to the weight ratio of bone meal and water is 1:3.5 to make 22 % bone meal slurry;

[0120] 2) Colloid mill grinding (high-shear colloid mill, model HSC-100R; Shanghai Yilu Electromechanical Equipment Co., Ltd.): Add the prepared bone powder slurry into the colloid mill and grind it into a bone powder colloid solution with a particle size of 40 μm;

[0121] 3) Phosphoric acid acidification: add phosphoric acid with...

Embodiment 2

[0135] Embodiment 2: enzymatic method gets bone gelatin

[0136] Concrete steps are with embodiment 1, and following part is slightly different:

[0137] 1) Phosphoric acid acidification: start the acidification stirring, heat up the collagen colloid, and raise the temperature of the collagen colloid to 45°C;

[0138] 2) Protease hydrolysis: start stirring, and slowly add the prepared 5% acidic protease solution. The weight ratio of acid protease solution to bone powder is 0.0144:1, heat preservation, stirring, and enzymolysis for 1.5 hours.

[0139] Under the condition of constant stirring, add 0.75% hydrogen peroxide (concentration: 27.5%) of the weight of bone powder to oxidize for 8 hours, and add the same amount of hydrogen peroxide (concentration: 27.5%) for the second time to oxidize for 24 hours. If time permits, it should be extended as much as possible. oxidation time;

[0140] 3) Flocculation: start stirring, slowly add calcium hydroxide suspension, stop adding c...

Embodiment 3

[0143] Embodiment 3: enzymatic method gets bone gelatin

[0144] Concrete steps are with embodiment 1, and following part is slightly different:

[0145] 1) Phosphoric acid acidification: start the acidification stirring, heat up the collagen colloid, and raise the temperature of the collagen colloid to 50°C;

[0146] 2) Enzymatic hydrolysis and decolorization: start stirring, slowly add the prepared 5% acid protease solution, add the amount of acid protease solution according to the weight ratio of acid protease solution and bone meal is 0.027:1, keep warm, stir, enzymolysis 1 Hour;

[0147] Under the condition of constant stirring, add 0.75% hydrogen peroxide (concentration: 27.5%) of the weight of bone powder to oxidize for 8 hours, and add the same amount of hydrogen peroxide (concentration: 27.5%) for the second time to oxidize for 24 hours. If time permits, it should be extended as much as possible. oxidation time;

[0148] 3) Start stirring, slowly add the calcium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com