Method for preparing lithium ionic cell anode material lithium vanadium fluorophosphate by hydro-thermal synthesis reaction

A technology for lithium vanadium phosphate and lithium ion battery, which is applied in the field of lithium vanadium phosphate lithium fluorophosphate positive electrode material prepared by hydrothermal synthesis reaction, which can solve the problem of uneven particle size distribution of synthetic materials, poor conductivity and cycle performance, and material failure. Uneven particle size distribution and other problems, to achieve the effect of inhibiting excessive growth, easy to control, and simple and convenient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

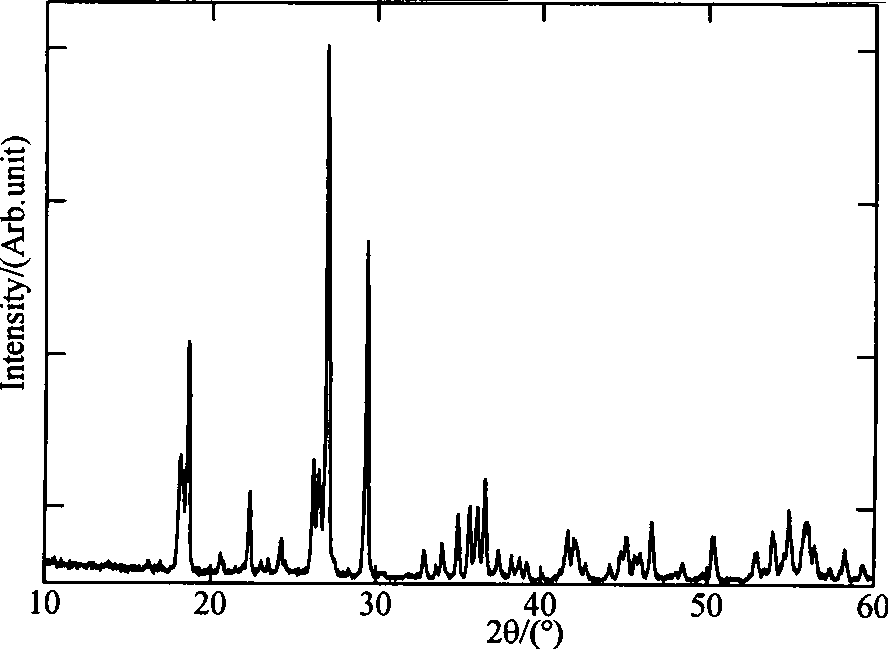

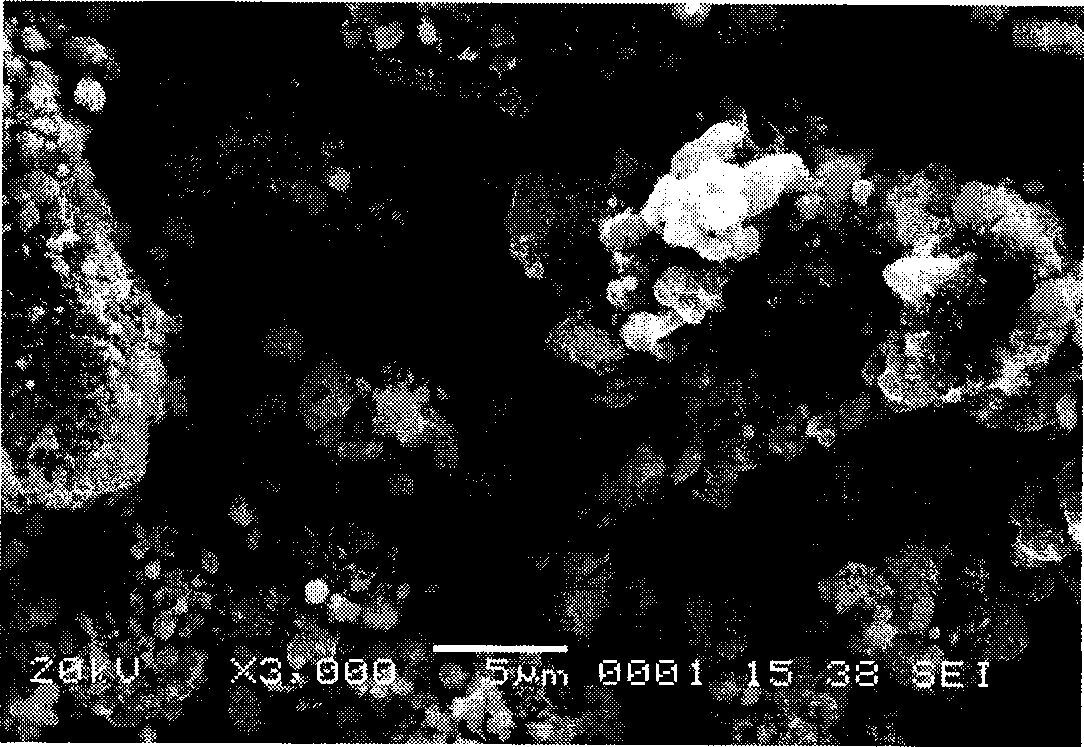

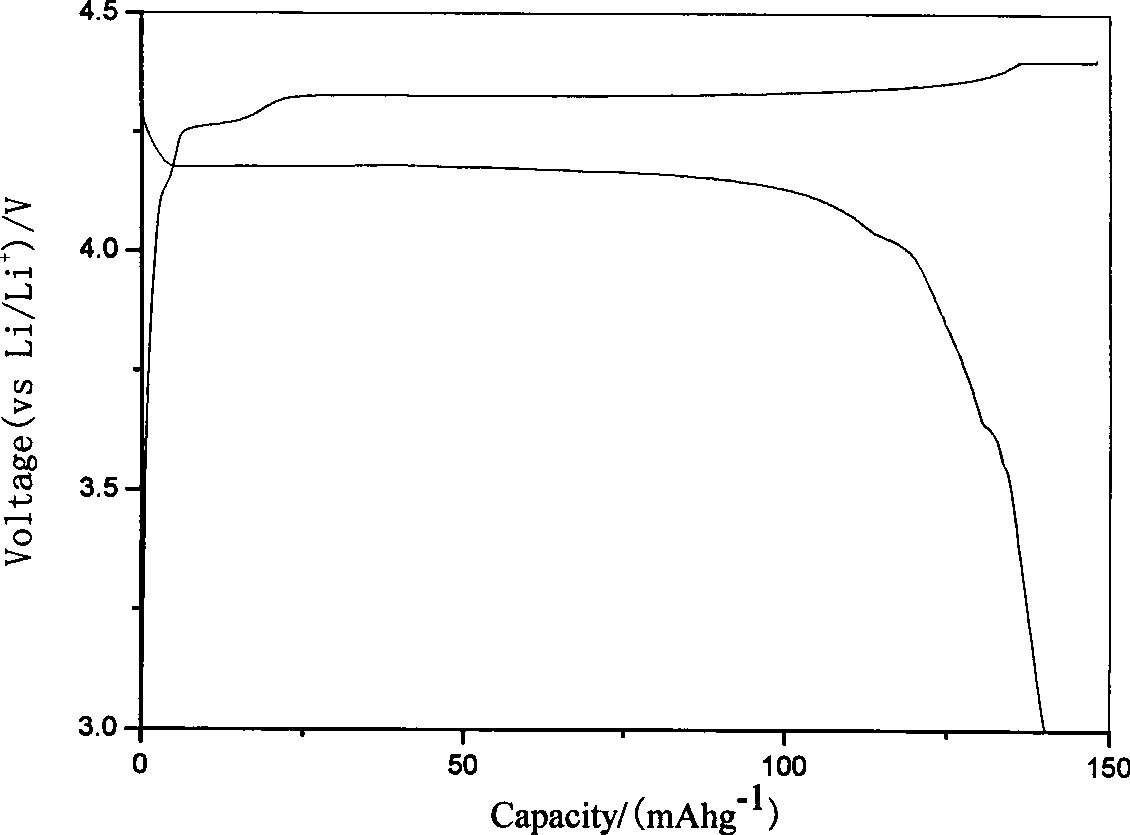

[0016] Dissolve 0.19mol of ammonium metavanadate, 0.21mol of lithium acetate, 0.105mol of malic acid, 0.20mol of ammonium fluoride and 0.21mol of diammonium hydrogen phosphate in water and mix them uniformly. After 1 day of reaction, the finished LiVPO is obtained after drying 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 0.1 μm. The obtained product was assembled into an experimental button battery to measure its charge-discharge specific capacity and cycle performance. The charge-discharge was carried out at a rate of 1C. The initial discharge capacity and the discharge capacity after 30 cycles are shown in Table 1.

[0017] Table 1 Experimental conditions and results of Example 1

Embodiment 2

[0020] Dissolve 0.20 mol ammonium metavanadate, 0.20 mol lithium fluoride, 0.10 mol adipic acid, 0.21 mol sodium fluoride and 0.20 mol ammonium dihydrogen phosphate in water and mix well, then react 1, 2, 3 and 4d, finished product LiVPO after drying 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 0.1 μm. The obtained product was assembled into an experimental button battery to measure its charge-discharge specific capacity and cycle performance. The charge-discharge was carried out at a rate of 1C. The initial discharge capacity and the discharge capacity after 30 cycles are shown in Table 2.

[0021] Table 2 Experimental conditions and results of Example 2

Embodiment 3

[0024] Dissolve 0.205mol of ammonium metavanadate, 0.19mol of lithium chloride, 0.095mol of citric acid, 0.19mol of potassium fluoride and 0.19mol of potassium phosphate in water, mix well, and react at 230°C, 280°C, 310°C, and 330°C respectively 4d, finished product LiVPO after drying 4 F. The obtained products were analyzed by X-ray diffraction, showing that they were all LiVPO 4 F, without any impurity phase, the particle size of the product obtained by SEM is about 0.1 μm. The obtained product was assembled into an experimental button battery to measure its charge-discharge specific capacity and cycle performance. The charge-discharge was carried out at a rate of 1C. The initial discharge capacity and the discharge capacity after 30 cycles are shown in Table 3.

[0025] Table 3 Experimental conditions and results of Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com