Manufacturing method of plastic sealed solar photovoltaic assembly

A technology of solar photovoltaic and production method, which is applied in the field of production of plastic-encapsulated solar photovoltaic modules, can solve the problems of easy rusting at scratches, difficulty in cleaning, and large production site occupation, so as to reduce costs, improve production efficiency, and solve problems easily The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

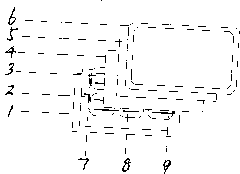

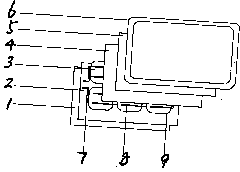

[0017] A method for making a plastic-encapsulated solar photovoltaic module, wherein a first EVA material layer 2 is provided on a glass layer 1, a battery sheet layer 3 is provided on the first EVA material layer, and a second EVA material layer 4 is provided on the battery sheet layer, Set the back plate material layer 5 on the second EVA material layer; the above parts are laminated and formed into a laminate by a laminator, and then a plastic frame 6 that acts as a plastic seal is set around the laminate, and the plastic seal is performed by ultrasonic heat melting .

[0018] The battery slice layer is connected by a plurality of small battery slices 9 through welding strips 8 and bus strips 7 . The lamination temperature of the laminator is between 130°C and 150°C, the total lamination time is between 15min and 45min, and the pressure is between -60Kpa and 0Kpa. During ultrasonic thermal melting, the air pressure is 0.3-0.8Mpa, the welding time is 0.6-2s, and the holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com