Method for preparing cathode material of lithium-ion battery, namely lithium vanadium fluorophosphates

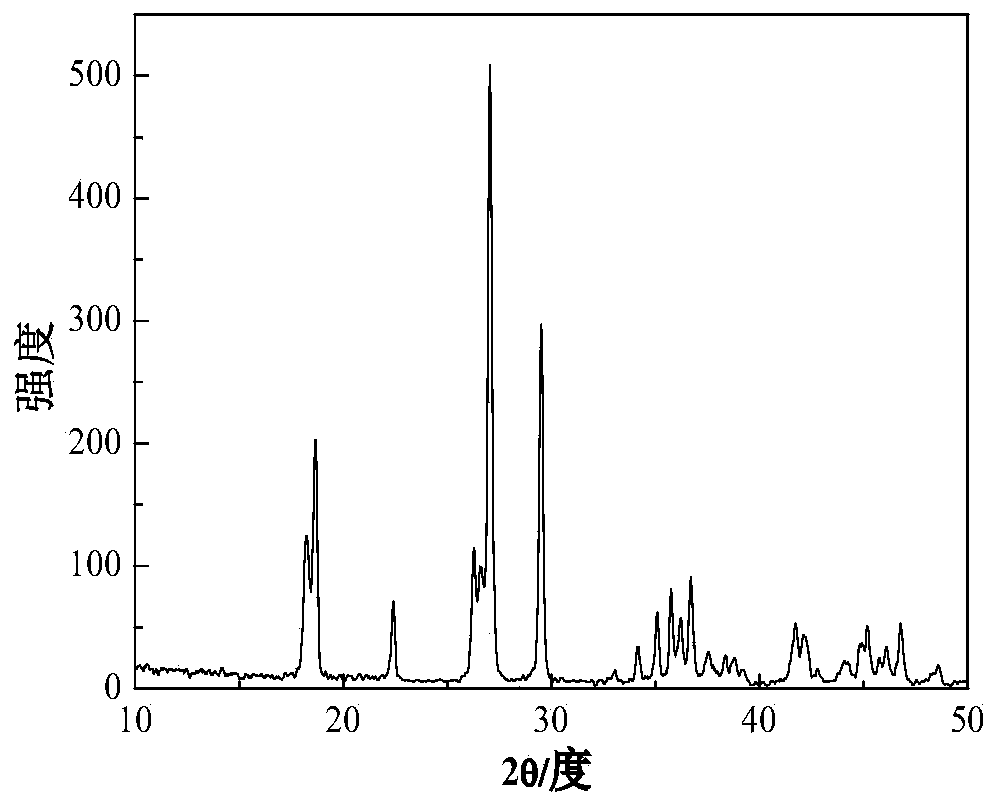

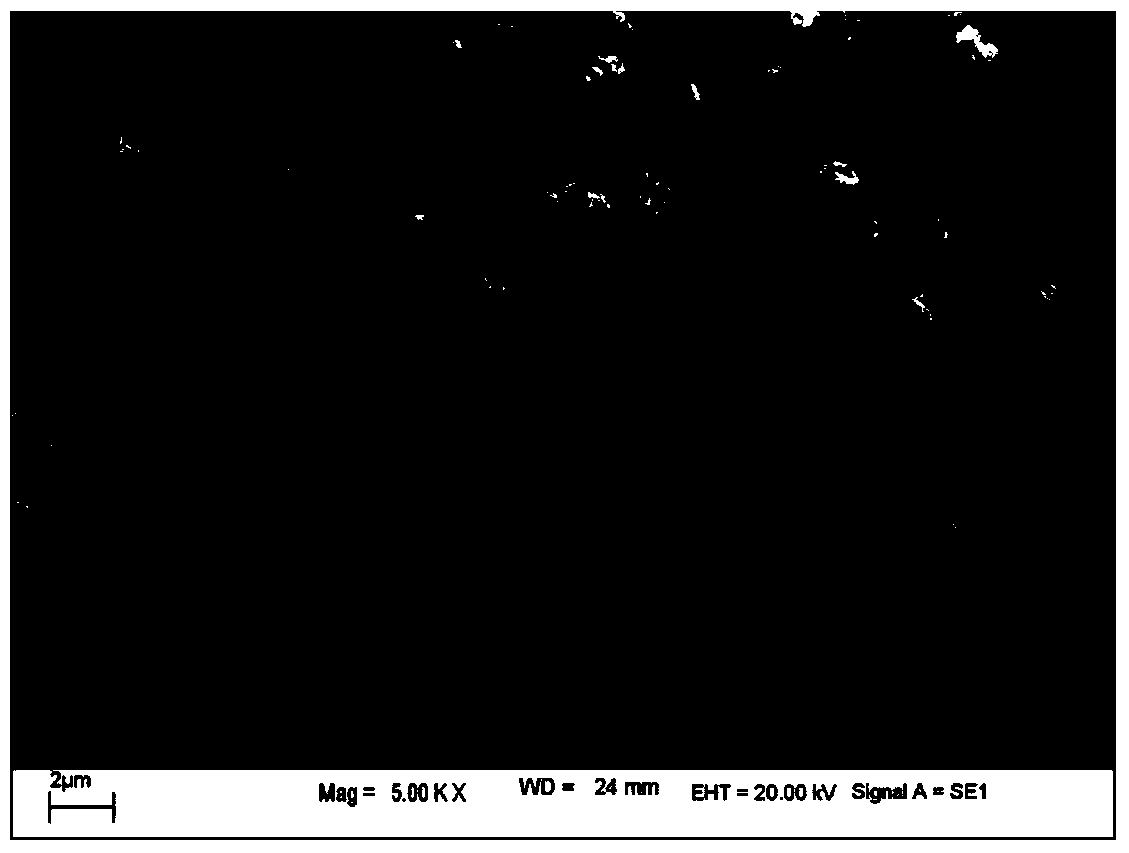

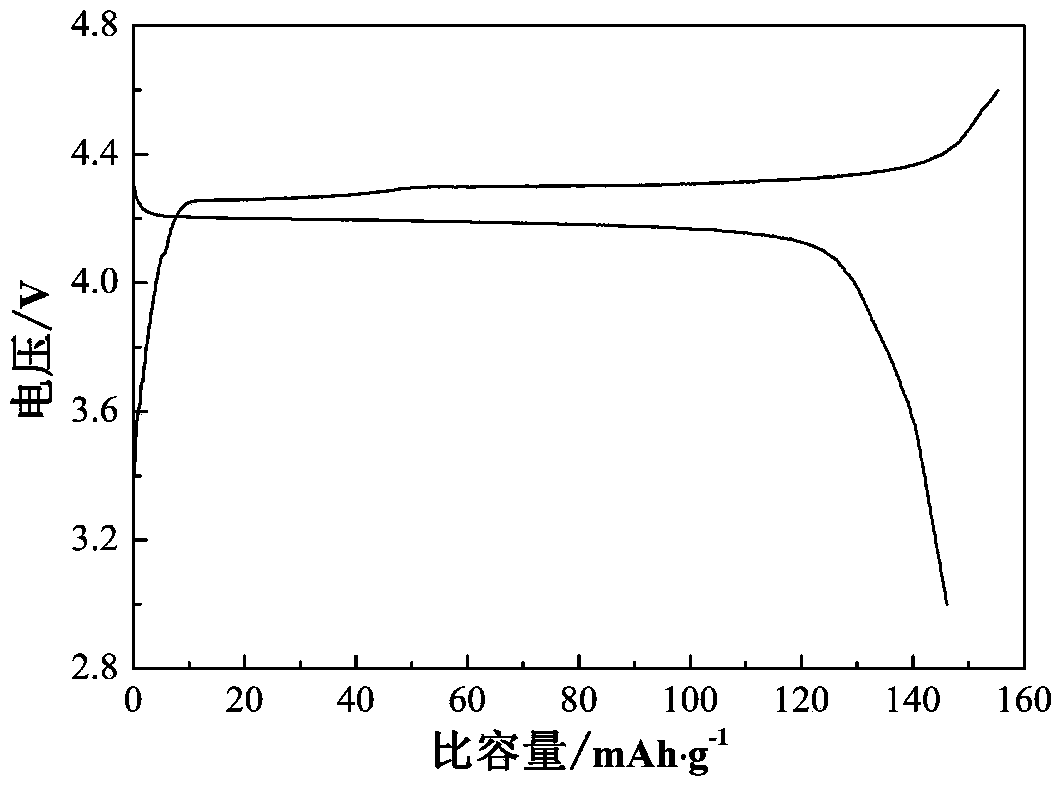

A technology of lithium vanadium fluorophosphate and lithium ion battery, which is applied in the field of preparing lithium vanadium fluorophosphate with excellent performance by mechanical activation-assisted solid-phase method, can solve problems such as easy generation of impurities, and achieve easy control, good cycle performance and particle size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preparation of LiVPO by two technical routes 4 F, as shown in Table 1, the first technical route is as follows: 0.1mol vanadium pentoxide, 0.2mol ammonium dihydrogen phosphate and 5g glucose (or 0.2mol citric acid) are placed in a high-energy ball mill container, and the container is filled with Nitrogen, add appropriate amount of acetone, O-ring seal, and ball mill at a certain speed for a certain time. The specific process is shown in Table 1. After the high-energy ball mill is mixed, the raw material mixture is dried, and then the dried precursor mixture is placed in the Heating to 350°C in a non-oxidizing atmosphere and keeping it for 4 hours, then continuing to raise the temperature to 500-800°C, and calcining at a constant temperature for 6 hours to obtain a precursor. Samples are numbered 1-10. The second technical route is as follows: the mixture of 0.1mol vanadium pentoxide, 0.2mol ammonium dihydrogen phosphate and 5g glucose is placed in a non-oxidative atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com