Method for preparing olivine structure lithium iron phosphate

A technology of olivine structure and lithium iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex preparation process, difficult industrialization, harsh conditions, etc., to improve electronic conductivity, burn The effect of low temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

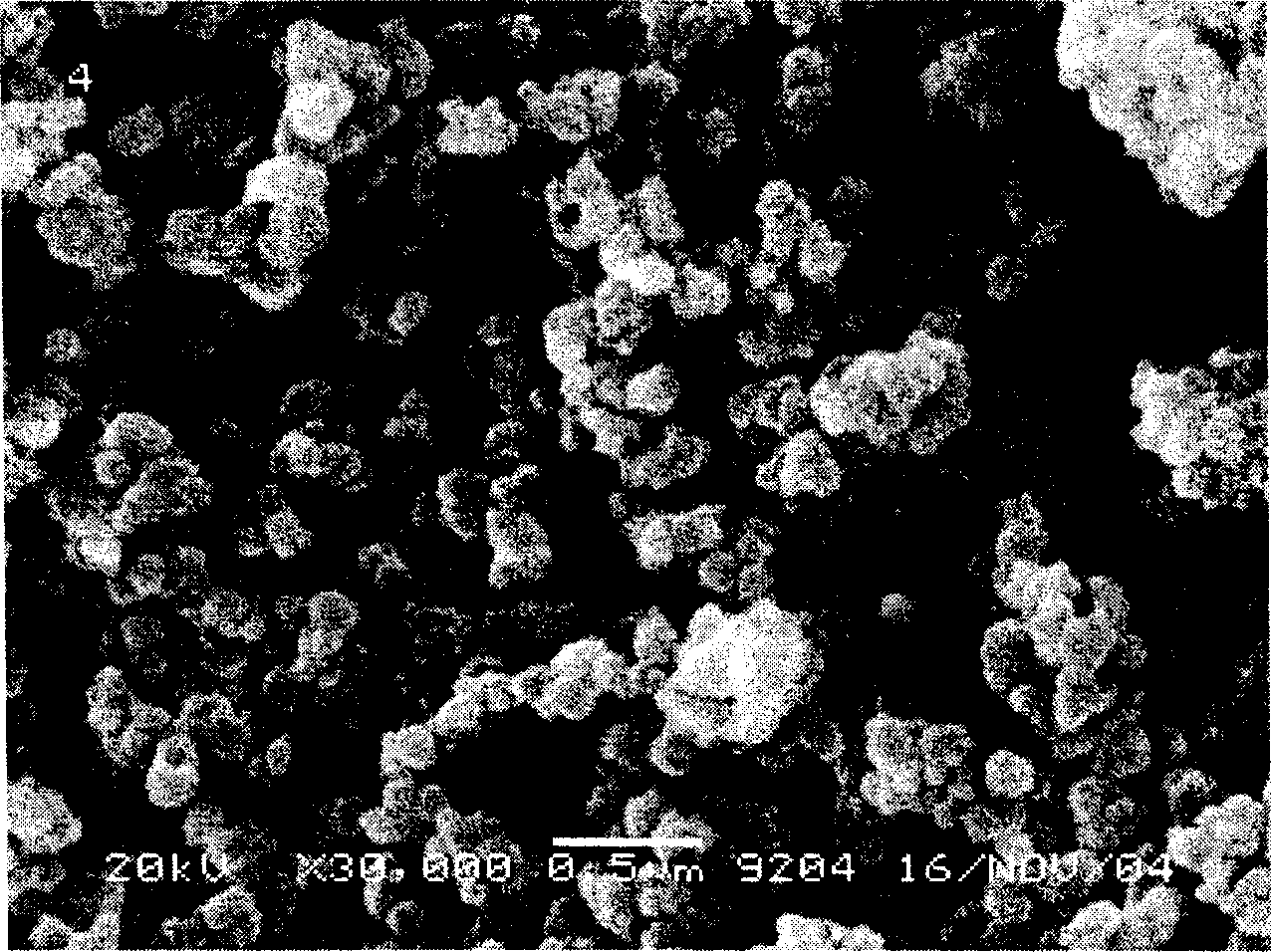

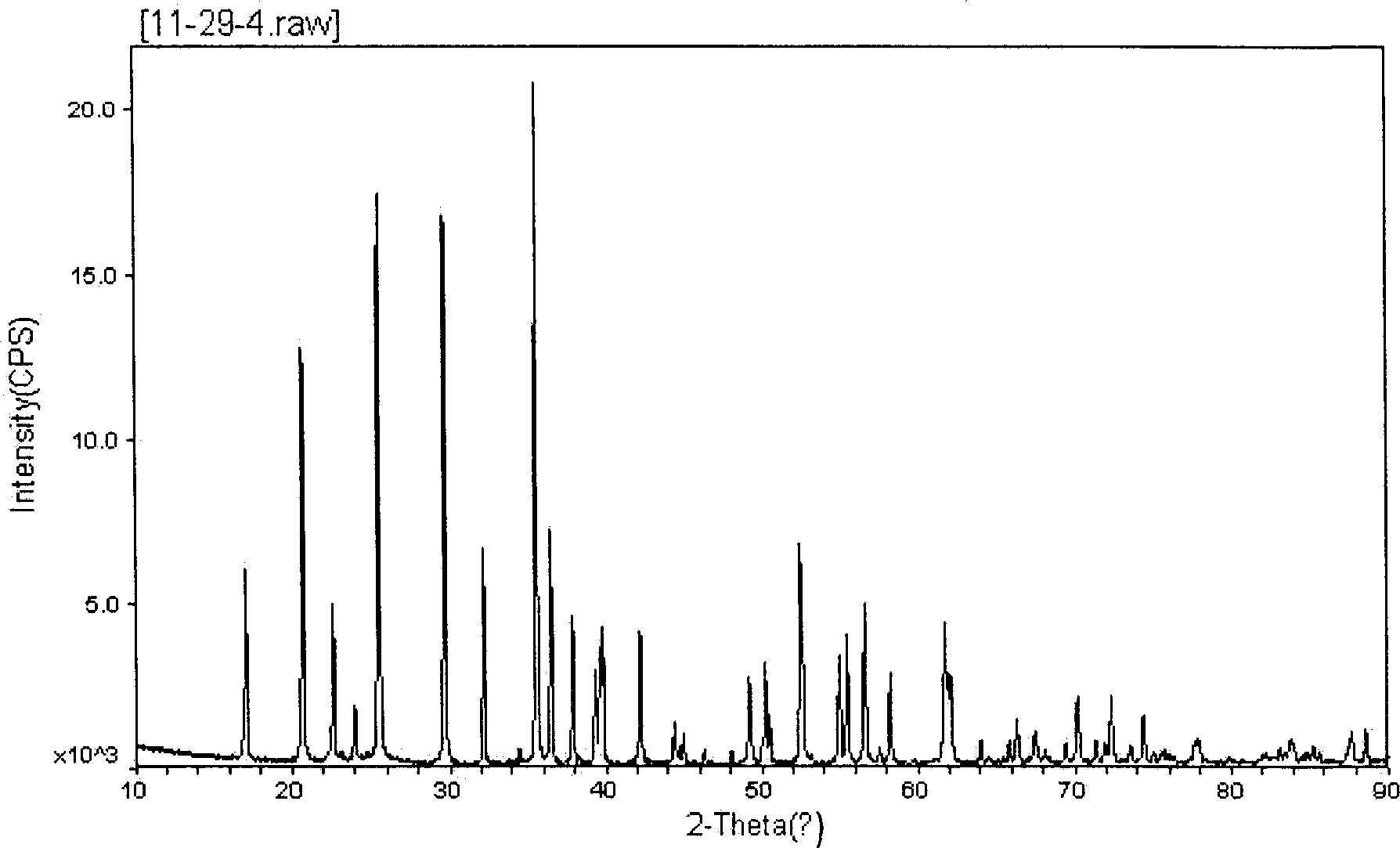

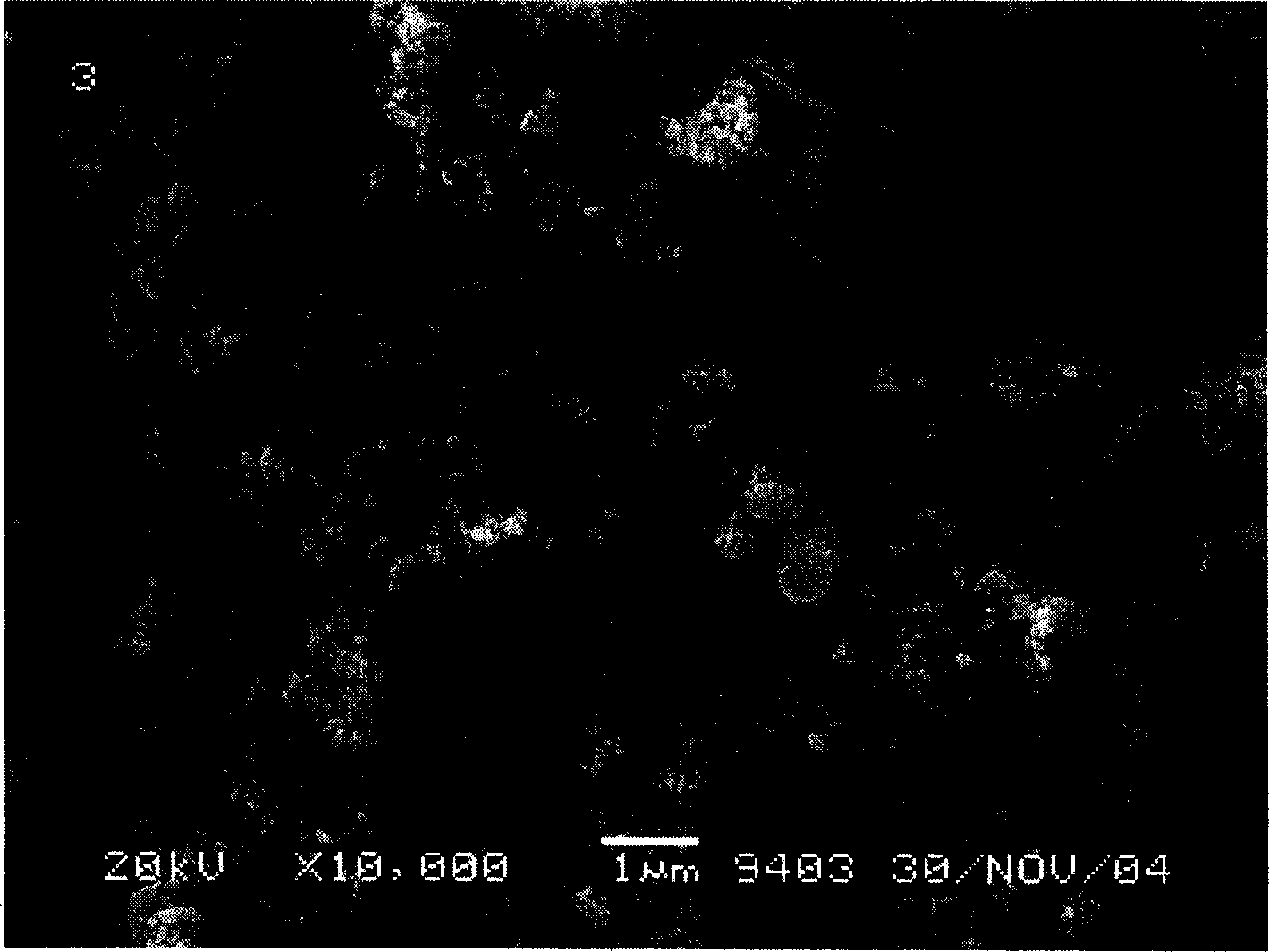

[0015] Example 1 After fully stirring and mixing 0.01mol / L ferrous chloride and 0.01mol / L phosphoric acid, add lithium hydroxide to control the pH value to 3.5, then add sodium peroxide to obtain a suspension, and the suspension is stirred vigorously stay in the reactor for 6 hours, then filter and wash, and the obtained filter cake (FePO 4 ) at 120°C for 12 hours. The dried precursor FePO 4 , carbon gel and lithium acetate are mixed by stoichiometry (carbon gel is calculated according to carbon content), while ensuring that the carbon gel is over 5%, after ball milling for 30min, then the mixture is put into the reduction furnace, and Ar gas is passed into it as In a protective atmosphere, heat to 500°C, 600°C, 700°C, and 800°C at a heating rate of 2°C / min and keep the temperature for 20 hours. The resulting product was analyzed by X-ray diffraction, showing that they were all LiFePO 4 , without any impurity phase, the particle size of the product obtained by SEM is about ...

Embodiment 2

[0017] Example 2 After fully stirring and mixing 0.01mol / L ammonium ferrous sulfate and 0.01mol / L phosphoric acid, add sodium hydroxide to control the pH value to 3.5, then add sodium peroxide to obtain a suspension, and the suspension is stirred vigorously stay in the reactor for 6 hours, then filter and wash, and the obtained filter cake (FePO 4 ) at 120°C for 12 hours. The dried precursor FePO 4 , carbon gel and lithium acetate are mixed by stoichiometry (carbon gel is calculated according to carbon content), while ensuring that the carbon gel is over 5%, after ball milling for 30min, then the mixture is put into the reduction furnace, and Ar gas is passed into it as Protect the atmosphere, heat up to 600°C at a heating rate of 2°C / min and keep warm for 10h, 20h, and 30h respectively. The resulting product was analyzed by X-ray diffraction, showing that they were all LiFePO 4 , without any impurity phase, the particle size of the product obtained by SEM is about 500nm. ...

Embodiment 3

[0019] Example 3 After fully stirring and mixing 2mol / L ferrous chloride and 2mol / L sodium dihydrogen phosphate, add ammonia water to control the pH value to 3.5, then add sodium peroxide to obtain a suspension, and the suspension is stirred vigorously Stay in the reactor for 6 hours, then filter and wash, the filter cake (FePO 4 ) at 120°C for 12 hours. The dried precursor FePO 4 , carbon black and lithium hydroxide are mixed stoichiometrically (carbon black is calculated according to carbon content), and at the same time ensure that the excess of carbon black is 2%, 5%, 7%, 10%, after ball milling for 30min, then put the mixture into the reduction furnace , heated to 600°C at a heating rate of 2°C / min and held for 20 hours under the protection of nitrogen gas. The resulting product was analyzed by X-ray diffraction, showing that they were all LiFePO 4 , without any impurity phase, the particle size of the product obtained by SEM is about 500nm. The obtained product was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com