Positive electrode of lithium sulfur battery and preparation method thereof

A lithium-sulfur battery and positive electrode technology, which is applied in the field of new energy, can solve the problems of poor electronic conductivity and ionic conductivity of electrode sheets, lower discharge efficiency, and increased battery internal resistance, so as to achieve better conductivity and smaller interface impedance , the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix elemental sulfur, conductive graphite and polytetrafluoroethylene uniformly at a mass ratio of 10:80:10, disperse them in an aqueous solution, and carry out sufficient mechanical stirring to obtain a carbon-coated slurry; evenly scrape the slurry on an aluminum foil current collector Above, after vacuum drying at 120°C, press to obtain a carbon-coated current collector, and the thickness of the carbon-coated layer is 30 μm;

[0038] The sulfur-carbon nanotube composite material, conductive carbon black and polytetrafluoroethylene are mechanically stirred and mixed uniformly at a mass ratio of 80:10:10, dispersed in an aqueous solution, and stirred to obtain a positive electrode active layer slurry; the slurry is scraped On the carbon-coated current collector, dry at 60° C. and then press to obtain the positive electrode sheet of the lithium-sulfur battery, wherein the thickness of the active layer is 150 μm.

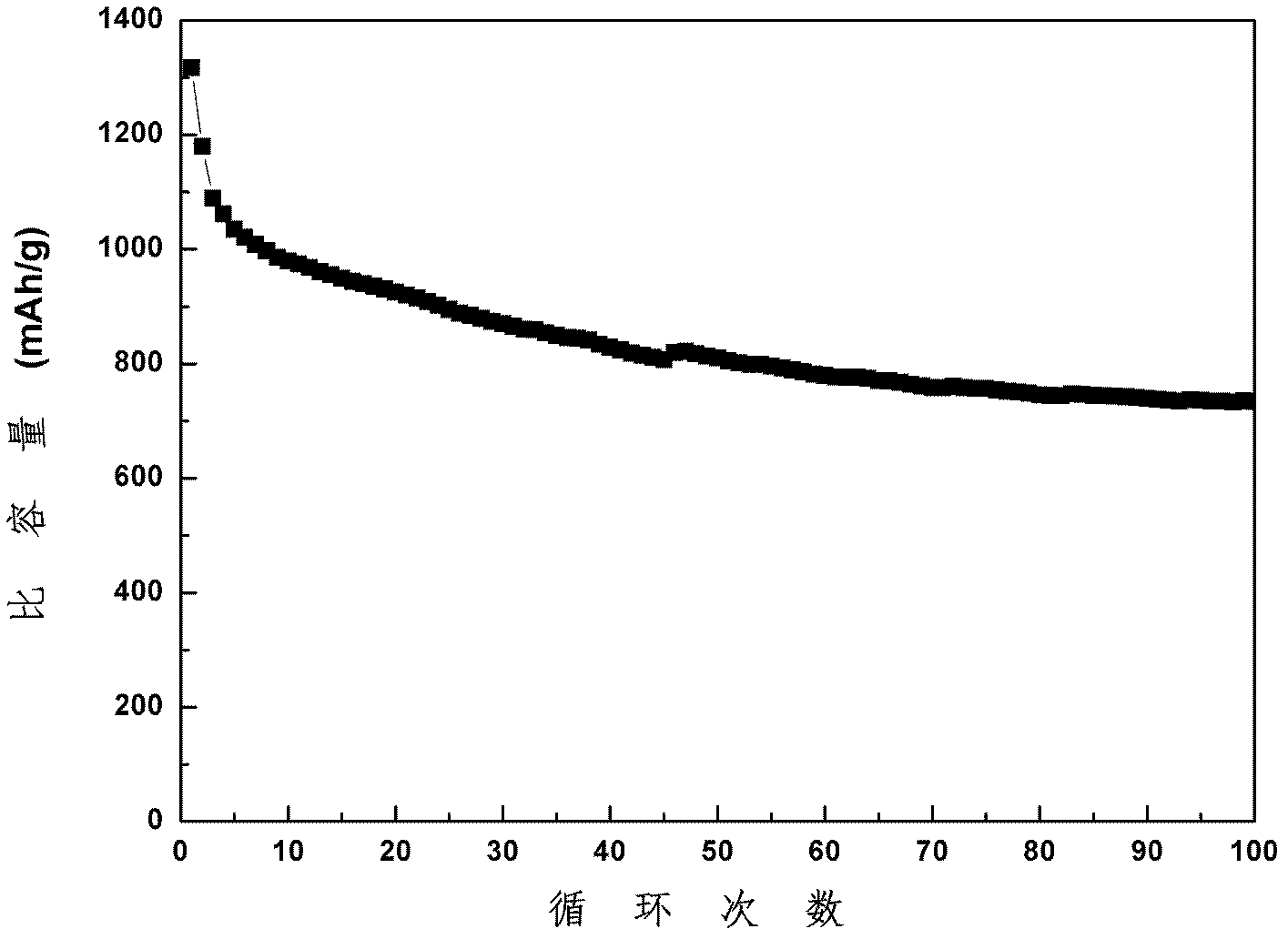

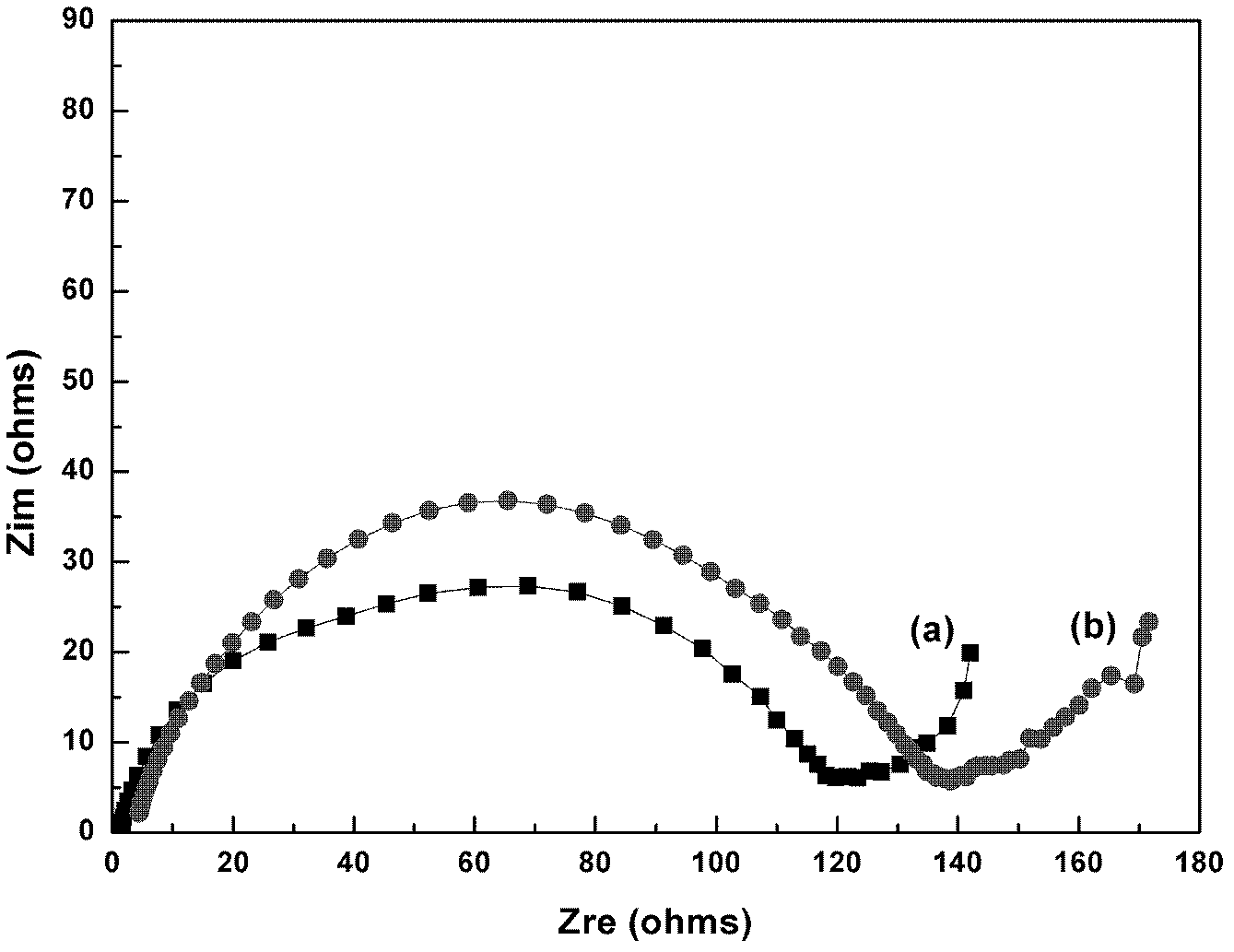

[0039] Electrochemical performance test:

[0040] The p...

Embodiment 2

[0042] Mix elemental sulfur, acetylene black, and polyvinylidene fluoride uniformly at a mass ratio of 1:80:19, disperse them in N-methylpyrrolidone solution, and carry out sufficient mechanical stirring to obtain carbon-coated slurry; uniformly print the slurry On the aluminum foil current collector, after vacuum drying at 100°C, press to obtain a carbon-coated current collector, and the thickness of the carbon-coated layer is 200nm;

[0043]Elemental sulfur, conductive carbon black and polytetrafluoroethylene were mechanically stirred and mixed uniformly in a mass ratio of 70:20:10, dispersed in an aqueous solution, and stirred to obtain a positive electrode active layer slurry; the slurry was rolled onto a carbon-coated surface On the current collector, after drying at 70°C, press to obtain the positive electrode sheet of the lithium-sulfur battery, wherein the thickness of the active layer is 90 μm.

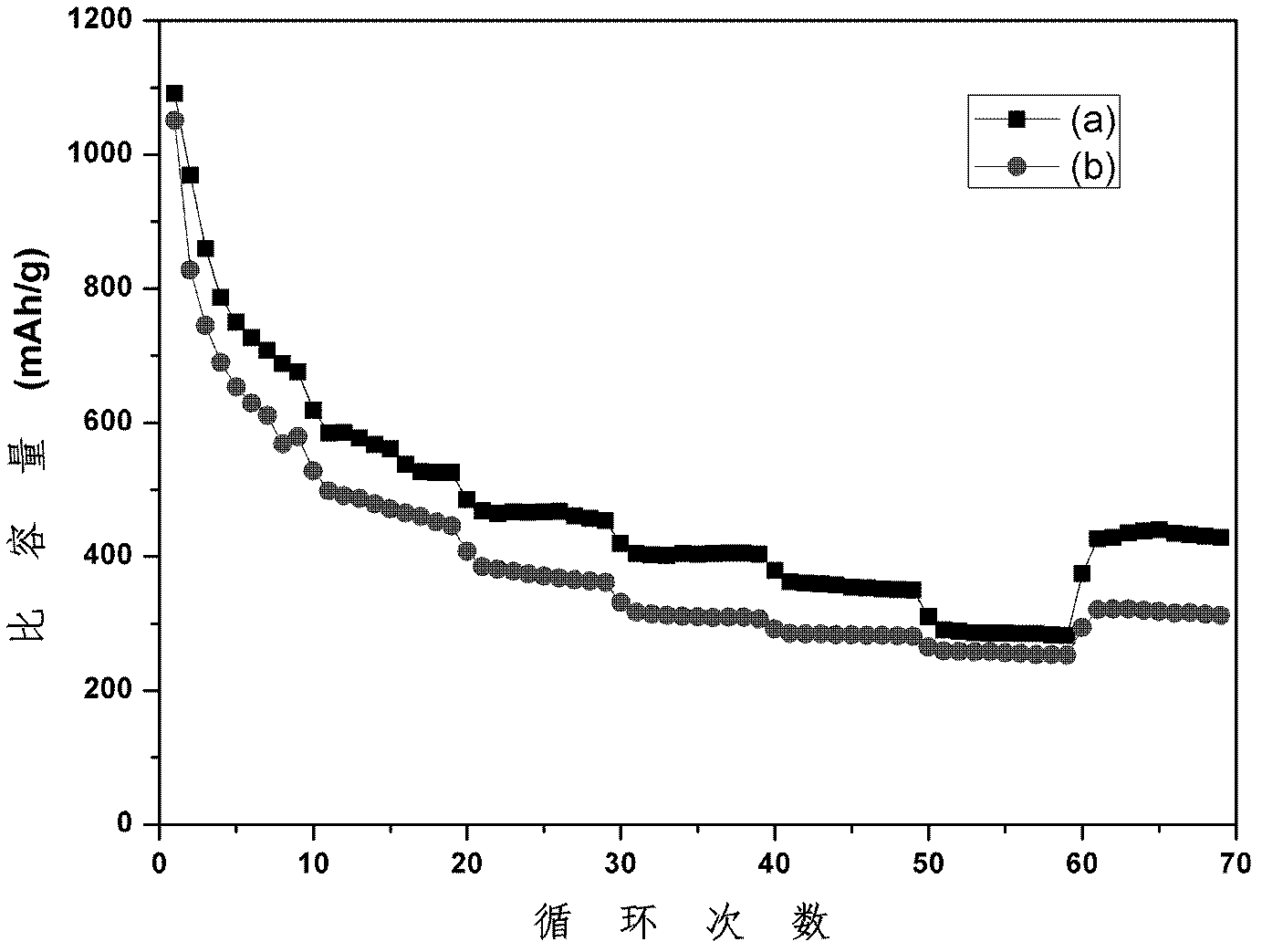

[0044] Electrochemical performance test:

[0045] The positive electrod...

Embodiment 3

[0047] Mix elemental sulfur, acetylene black, and polyvinylidene fluoride uniformly at a mass ratio of 10:70:20, disperse them in N-methylpyrrolidone solution, and carry out sufficient mechanical stirring to obtain carbon-coated slurry; scrape the slurry On the aluminum foil current collector, after vacuum drying at 110°C, press to obtain a carbon-coated current collector, and the thickness of the carbon-coated layer is 600nm;

[0048] Mix sulfur-carbon nanotube composite material, conductive carbon black, and polyvinylidene fluoride with mechanical stirring at a mass ratio of 80:10:10, disperse them in N-methylpyrrolidone solution, and perform mechanical stirring to obtain positive active layer slurry ; Scrape-coat the slurry on the carbon-coated current collector, dry it at 70° C. and press it to obtain the positive electrode sheet of the lithium-sulfur battery, wherein the thickness of the active layer is 150 μm.

[0049] Electrochemical performance test:

[0050] The posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com