Vanadium oxide ultra-thin nanobelt with embedded ions and preparation method and application thereof

A technology of vanadium oxide, ion intercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

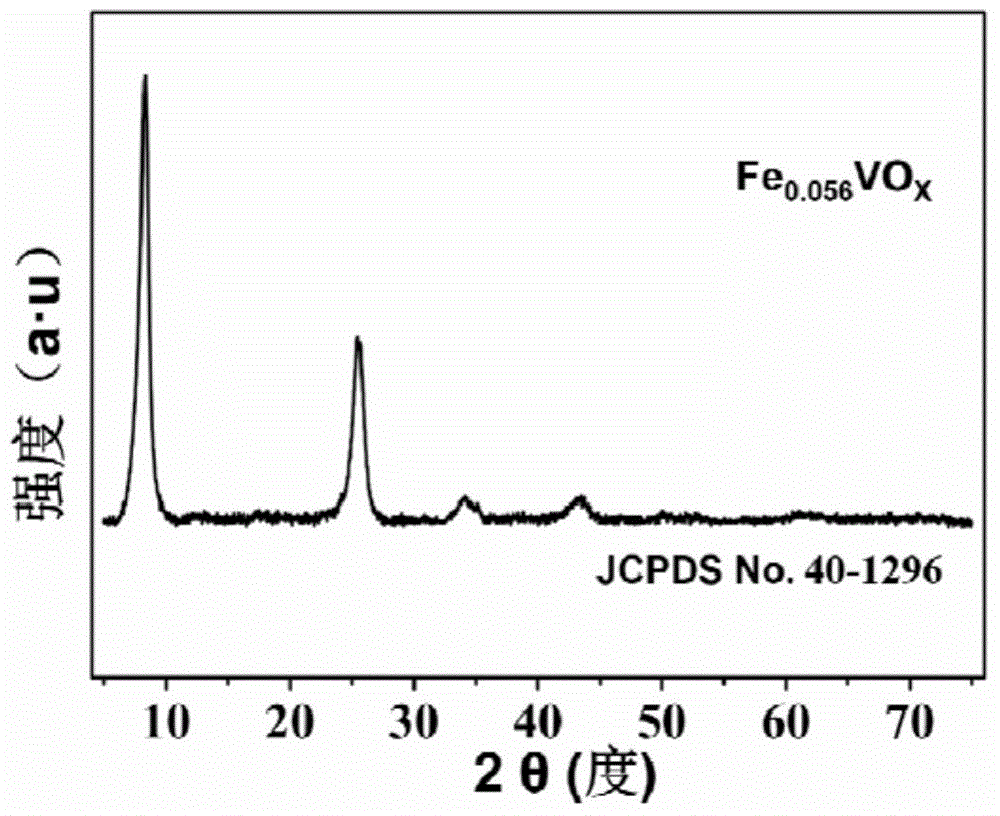

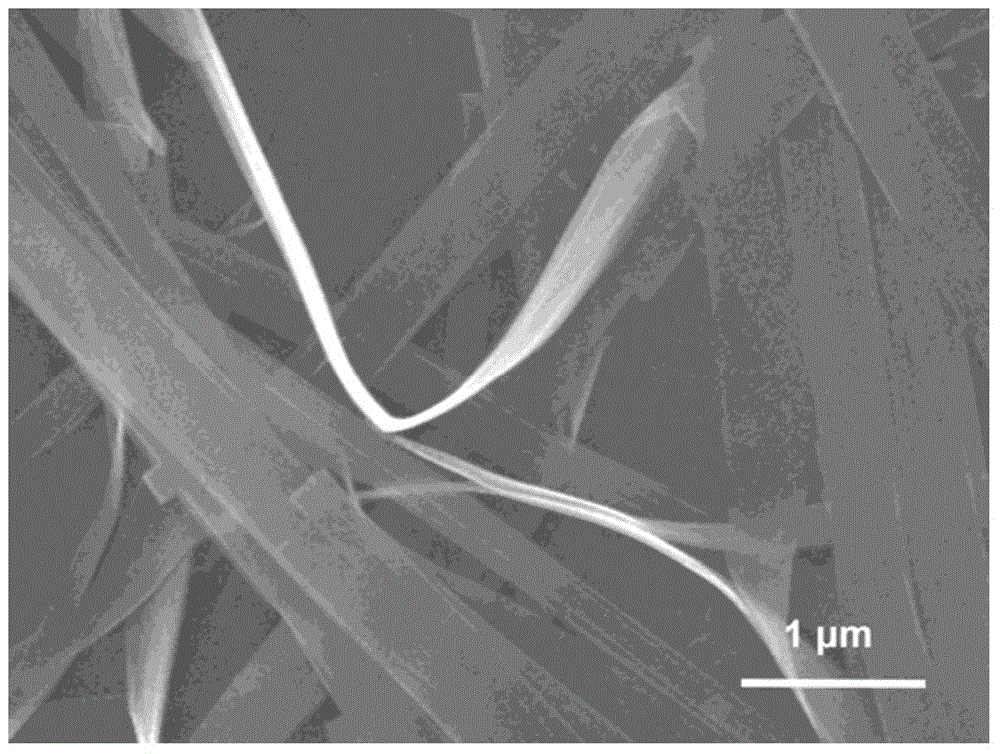

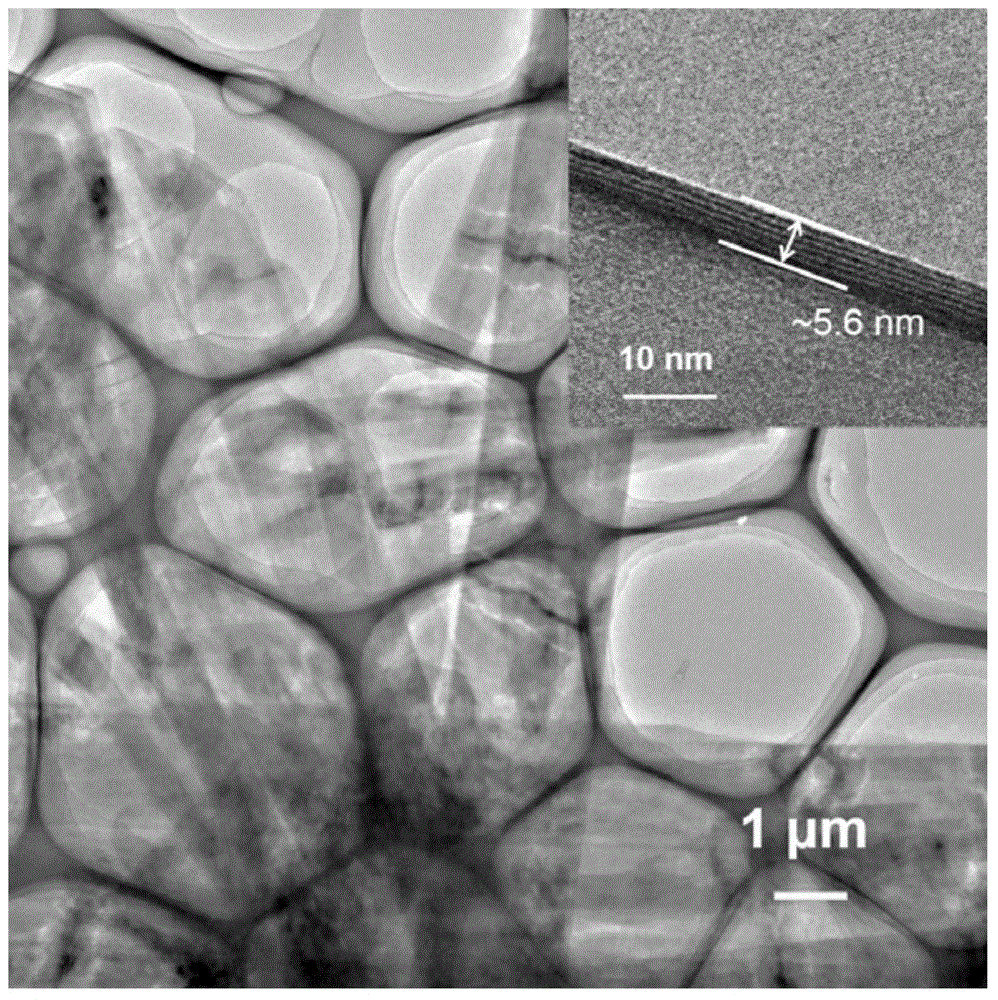

Embodiment 1

[0037] A method for preparing an ion-embedded vanadium oxide ultrathin nanoribbon, comprising the steps of:

[0038] 1) Weigh 0.1mmol iron acetylacetonate and dissolve it in deionized water, wherein the amount of iron acetylacetonate is the same as the V that is about to be added in step 2). 2 o 5 sol corresponds proportionally to each mole of V 2 o 5 The sol corresponds to 0.1mmol iron acetylacetonate, fully stirred to dissolve;

[0039] 2) Slowly add 1 mmol of vanadium pentoxide sol to the solution obtained in step 1), that is, the concentration of vanadium pentoxide in the solution is 0.017mol / L, and fully stir;

[0040] 3) Transfer the solution obtained in step 2) into a reaction kettle, heat at 180° C. for 48 hours, take out the reaction kettle, and naturally cool to room temperature;

[0041] 4) centrifuging the product obtained in step 3), collecting the precipitate and repeatedly washing the precipitate with water and absolute ethanol;

[0042] 5) disperse the pre...

Embodiment 2

[0049] A method for preparing an ion-embedded vanadium oxide ultrathin nanoribbon, comprising the steps of:

[0050] 1) Weigh 0.05mmol calcium acetylacetonate and dissolve it in deionized water, wherein the amount of calcium acetylacetonate is the same as that of V that is about to be added in step 2). 2 o 5 sol corresponds proportionally to each mole of V 2 o 5 The sol corresponds to 0.05 calcium acetylacetonate, fully stirred to dissolve;

[0051] 2) Slowly add 1 mmol of vanadium pentoxide sol to the solution obtained in step 1), that is, the concentration of vanadium pentoxide in the solution is 0.017mol / L, and fully stir;

[0052] 3) Transfer the solution obtained in step 2) into a reaction kettle, heat at 200° C. for 24 hours, take out the reaction kettle, and naturally cool to room temperature;

[0053] 4) centrifuging the product obtained in step 3), collecting the precipitate and repeatedly washing the precipitate with water and absolute ethanol;

[0054] 5) dispe...

Embodiment 3

[0059] A method for preparing an ion-embedded vanadium oxide ultrathin nanoribbon, comprising the steps of:

[0060] 1) Weigh 1mmol molybdenum acetylacetonate and dissolve it in deionized water, wherein the amount of molybdenum acetylacetonate is the same as that of the V that will be added in step 2) 2 o 5 sol corresponds proportionally to each mole of V 2 o 5 The sol corresponds to 1 mmol of molybdenum acetylacetonate, fully stirred to dissolve;

[0061] 2) Slowly add 1 mmol of vanadium pentoxide sol to the solution obtained in step 1), that is, the concentration of vanadium pentoxide in the solution is 0.017mol / L, and fully stir;

[0062] 3) Transfer the solution obtained in step 2) into a reaction kettle, heat at 200° C. for 24 hours, take out the reaction kettle, and naturally cool to room temperature;

[0063] 4) centrifuging the product obtained in step 3), collecting the precipitate and repeatedly washing the precipitate with water and absolute ethanol;

[0064] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com