Preparation method for nano titanium dioxide lithium ion battery cathode material

A nano-titanium dioxide and lithium-ion battery technology, applied in the direction of titanium dioxide, battery electrodes, titanium oxide/hydroxide, etc., can solve problems such as long reaction cycle, difficult control of hydrolysis speed, complex reaction mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of nano-titanium dioxide lithium ion battery negative electrode material, comprising:

[0031] a) dissolving the titanium source compound in a mixed solution of acetic acid and ethanol; obtaining a first reaction solution;

[0032] b) mixing and dissolving oxalic acid in ethanol to obtain a second reaction solution;

[0033] c) mixing the first reaction solution with the second reaction solution, reacting oxalic acid with a titanium source compound to generate a precipitate;

[0034] d) roasting the precipitate obtained in the step c) to obtain the nano-titanium dioxide lithium ion battery negative electrode material.

[0035] Nano-titanium dioxide is a material that can replace carbon materials as the negative electrode of lithium-ion batteries. Since nano-titanium dioxide is prepared as a gel material, it needs to be dried when preparing the negative electrode material, and the drying time is long, which affects the use of ...

Embodiment 1

[0047] This example is used to illustrate the preparation of the silicon / carbon composite negative electrode material for lithium ion batteries provided by the present invention.

[0048] (1) Dissolve 5 mL of glacial acetic acid in 500 mL of ethanol solution, then add 6 mL of tetrabutyl titanate dropwise, and stir evenly to prepare a solution.

[0049] Add 1.89g of oxalic acid into a mixed solution of 30mL of water and 30mL of ethanol, and stir to prepare solution b.

[0050] (2) Put the solution b in a water bath at 50°C, and add the solution a dropwise, and stir for 3 hours. Aging at room temperature.

[0051] (3) Wash the obtained precipitate with ethanol and water respectively, and sinter at 400°C for 4h.

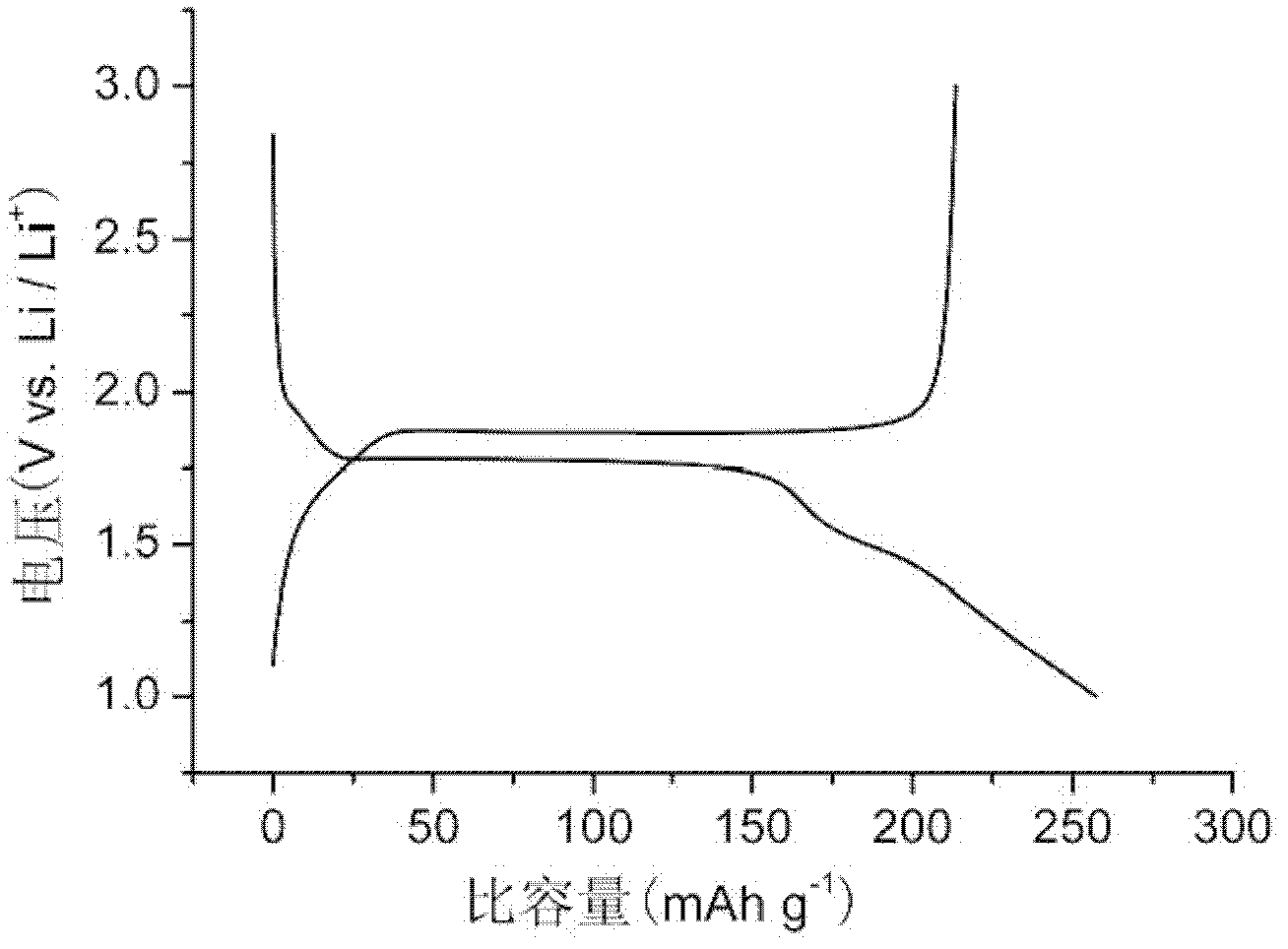

[0052] The obtained product has a lithium intercalation capacity of 257mAh / g for the first time, and a lithium delithiation capacity of 213mAh / g for the first time. See attached figure 1 .

Embodiment 2

[0054] (1) Dissolve 0.2mL of glacial acetic acid into 18mL of ethanol solution, then add 5mL of tetrabutyl titanate dropwise, and stir evenly to prepare a solution.

[0055] Add 2.4g of oxalic acid and 0.6g of sodium dodecylbenzenesulfonate to a mixed solution of 30mL of water and 30mL of ethanol, and stir to prepare solution b.

[0056] (2) Put the solution b in a water bath at 70°C, and add the solution a dropwise, and stir for 5 hours. Aging at room temperature.

[0057] (3) Wash the obtained precipitate with ethanol and water respectively, and sinter at 450°C for 4h.

[0058] The morphology of the obtained product is shown in the appendix figure 2 . After 100 cycles at 1C, the capacity basically does not decay. See attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com