Preparation method of titanium carbide

A technology of titanium carbide and iron-titanium, which is applied in the direction of titanium carbide, chemical instruments and methods, carbides, etc., can solve the problems of limited particle size of titanium carbide, difficulty in preparing nano-scale titanium carbide products, etc., and achieve low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

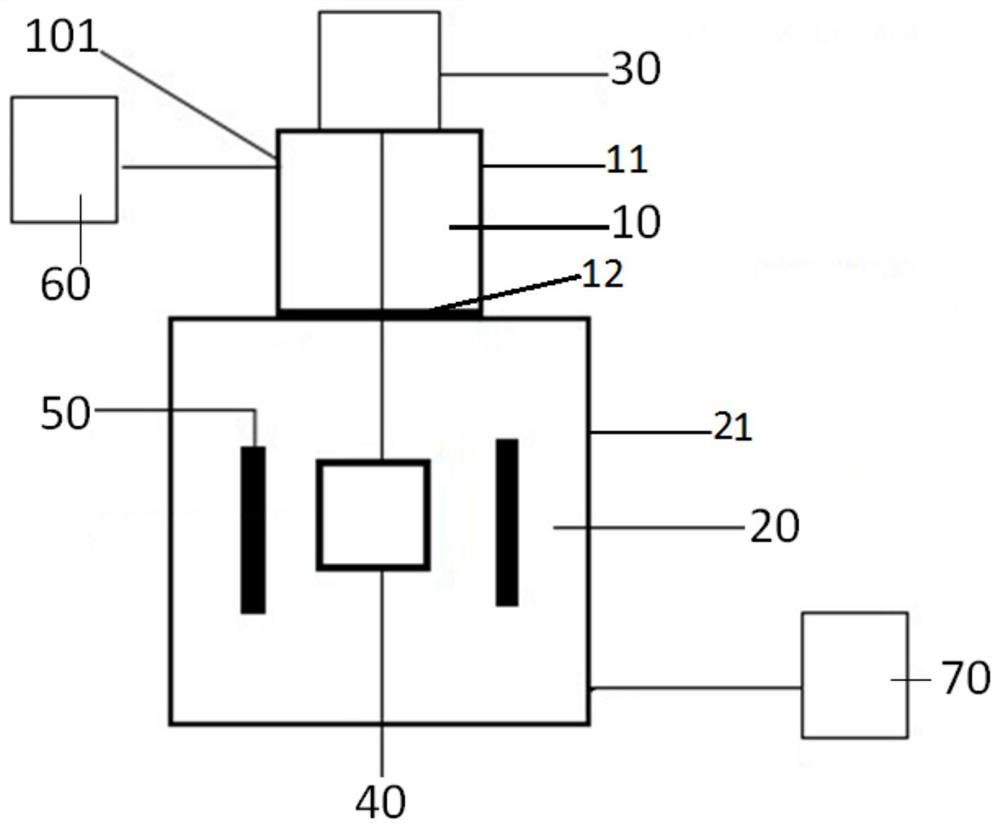

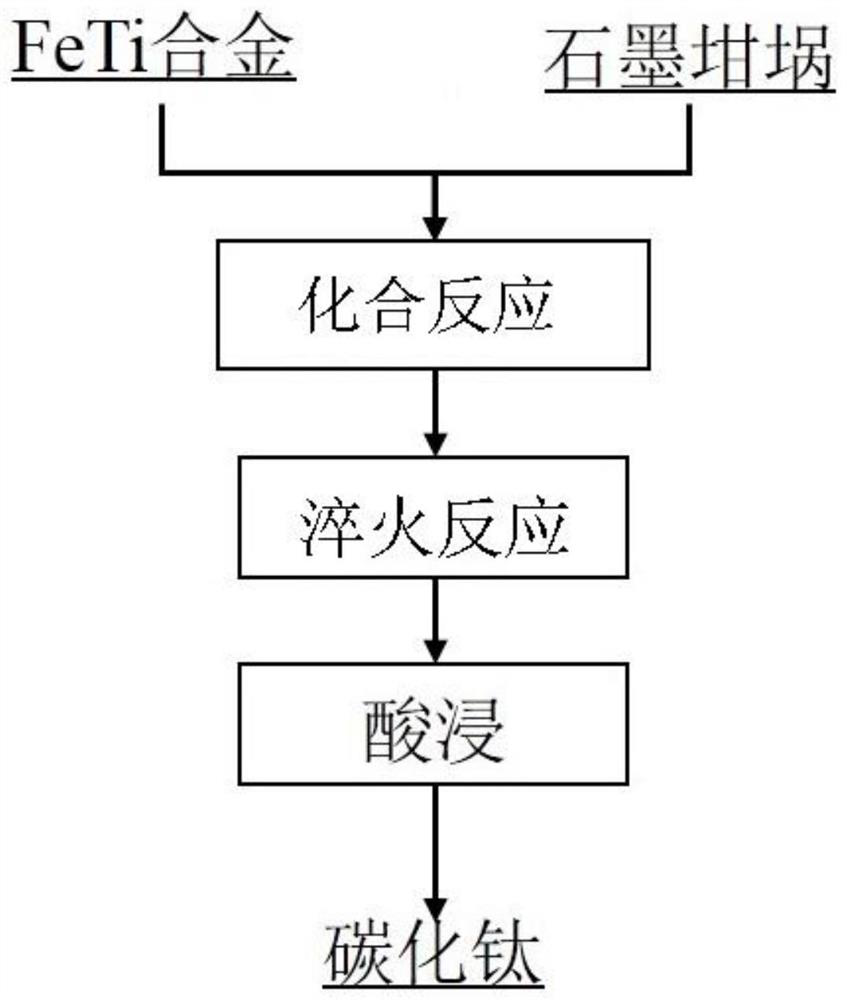

[0022] As described in the background technology, the particle size of titanium carbide in the existing titanium carbide preparation method is limited by the particle size of raw materials, which makes it difficult to prepare nano-sized titanium carbide products. In order to solve the above-mentioned technical problems, the present application provides a method for preparing titanium carbide, the preparation method comprising: placing a graphite crucible containing an iron-titanium binary alloy in a vacuum reaction furnace, and heating to make the iron-titanium binary alloy The alloy is melted and compounded to obtain a compounded product; the compounded product is quenched to obtain a quenched product; and the quenched product is subjected to acid leaching to remove metallic iron to obtain titanium carbide.

[0023] Iron-titanium alloy and high-purity graphite crucible are used as raw materials. During the heating process, metallic iron will form Fe-C binary low-melting point ...

Embodiment 1

[0035] Put the FeTi alloy into a high-purity graphite crucible, and the mole fraction of Ti in the FeTi alloy is 5%. The vacuum degree in the vacuum reaction furnace was evacuated to 0.01Pa, the electromagnetic door was closed, and the temperature of the reaction furnace was raised to 1500°C at a rate of 10°C, and kept for 20 minutes to carry out the compound reaction and obtain the compound product.

[0036] After the heat preservation is over, close the heating program, open the electromagnetic door, raise the graphite crucible to the quenching zone and spray high-purity argon gas for quenching to obtain the quenched product.

[0037] Use 1mol / L sulfuric acid to pickle the quenched product to remove metallic iron and obtain titanium carbide particles with a particle size of 130nm. The leaching solution is evaporated to obtain FeSO 4 . FeSO 4 Put it in a reaction furnace and heat it to 600°C to get Fe 2 o 3 , and SO 2 and SO 3 of mixed gas. The mixed gas can be used t...

Embodiment 2

[0039] Put the FeTi alloy into a high-purity graphite crucible, and the mole fraction of Ti in the FeTi alloy is 20%. The vacuum degree in the vacuum reaction furnace was evacuated to 0.1 Pa, the electromagnetic door was closed, and the temperature of the reaction furnace was raised to 1600° C. at a rate of 10° C., and kept for 30 minutes to carry out the compound reaction and obtain the compound product.

[0040] After the heat preservation is over, close the heating program, open the electromagnetic door, raise the graphite crucible to the quenching zone and spray high-purity argon gas for quenching to obtain the quenched product.

[0041] Use 2mol / L sulfuric acid to pickle the quenched product to remove metallic iron and obtain titanium carbide particles with a particle size of 160nm. The leaching solution is evaporated to obtain FeSO 4 . FeSO 4 Put it in a reaction furnace and heat it to 650°C to get Fe 2 o 3 , and SO 2 and SO 3 of mixed gas. The mixed gas can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com