YSZ electrolyte slurry and preparation method thereof

An electrolyte and electrolyte membrane technology, applied in the field of YSZ electrolyte slurry and its preparation, can solve the problems of poor electrolyte layer compactness, grain growth, easy agglomeration, etc., and achieve uniform membrane structure, good compactness, good mutual fill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

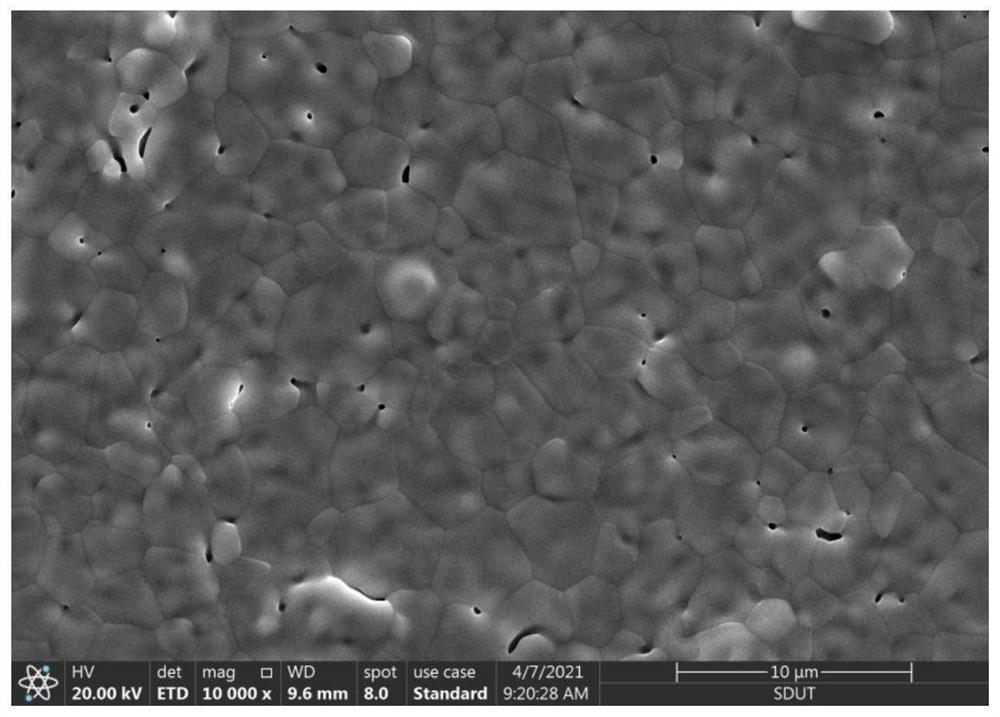

[0039] The present invention also provides the preparation method of YSZ electrolyte slurry of the present invention, comprises the steps:

[0040] After ball milling the YSZ powder, the submicron YSZ powder with a particle size of D50=0.1-0.5 μm and the micron-sized YSZ powder with a particle size of D50=1-1.2 μm were obtained respectively, and the particle size was prepared by the sol-gel method. Nanoscale YSZ powder with D50=0.05-0.07μm;

[0041] Weigh ethyl cellulose and terpineol, stir and dissolve until the mixed solution is clarified to obtain a binding agent;

[0042] Mixing nano-scale YSZ powder, submicron-scale YSZ powder and micron-scale YSZ powder with a binder, adding a dispersant, and ball milling to obtain the YSZ electrolyte slurry of the present invention.

[0043] In the present invention, grinding aid is added during ball milling of YSZ powder. The ball milling beads include zirconia balls with diameters of 0.3mm, 3mm and 6mm. According to the order of diam...

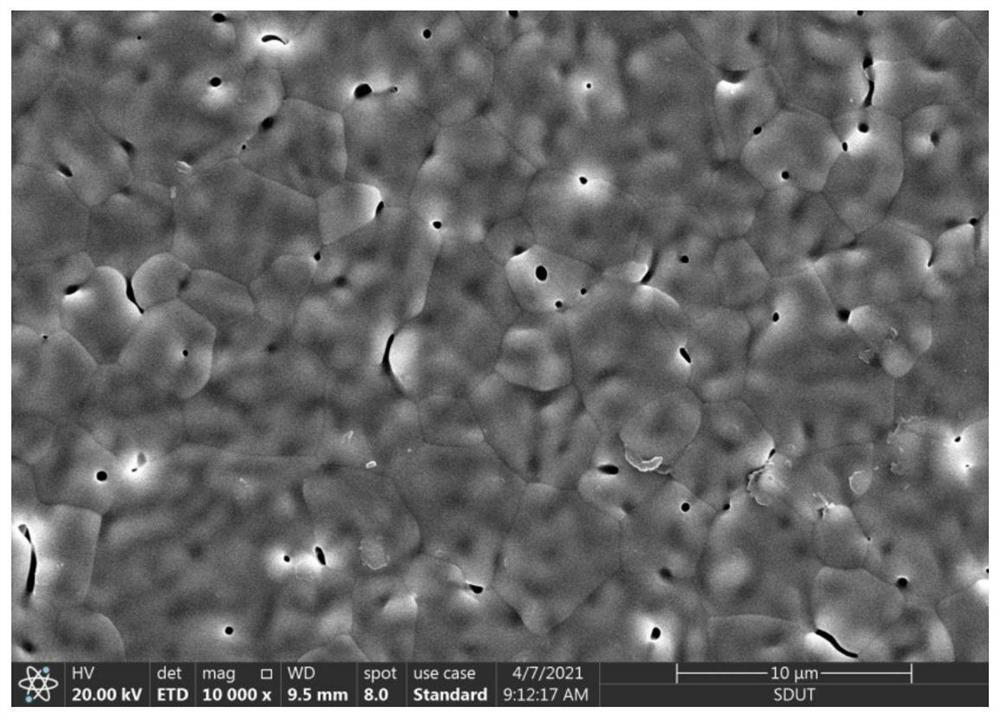

Embodiment 1

[0048] This embodiment provides a YSZ electrolyte slurry, including YSZ powder, binder and dispersant, wherein, YSZ powder includes nanoscale YSZ powder, submicron YSZ powder and micron YSZ powder; The particle size of YSZ powder is D50=0.05μm, the particle size of submicron YSZ powder is D50=0.1μm and D50=0.3μm, and the particle size of micron YSZ powder is D50=1μm.

[0049] In this embodiment, the YSZ electrolyte slurry includes 75 parts of YSZ powder, 61 parts of binder and 0.7 part of dispersant in parts by weight.

[0050] In this embodiment, the YSZ powder includes 5 parts of nano-sized YSZ powder, 55 parts of submicron-sized YSZ powder and 15 parts of micron-sized YSZ powder in parts by weight. Among them, the submicron YSZ powder includes 10 parts of submicron YSZ powder with a particle size of D50=0.1 μm, and 45 parts of submicron YSZ powder with a particle size of D50=0.3 μm.

[0051] In this embodiment, the dispersant is a coupling agent, the coupling agent is a si...

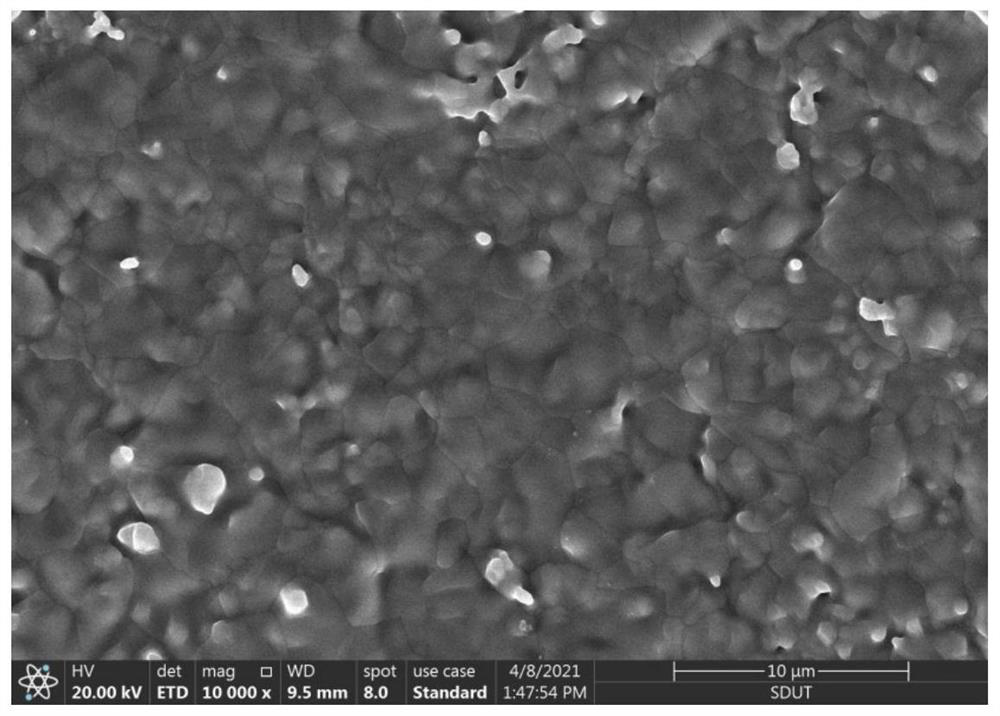

Embodiment 2

[0058] This embodiment provides a YSZ electrolyte slurry, including YSZ powder, binder and dispersant, wherein, YSZ powder includes nanoscale YSZ powder, submicron YSZ powder and micron YSZ powder; The particle size of YSZ powder is D50=0.06μm, the particle size of submicron YSZ powder is D50=0.15μm and D50=0.4μm, and the particle size of micron YSZ powder is D50=1.1μm.

[0059] In this embodiment, the YSZ electrolyte slurry includes 92 parts of YSZ powder, 75 parts of binder and 1.5 parts of dispersant in parts by weight.

[0060] In this embodiment, the YSZ powder includes 7 parts by weight of nanoscale YSZ powder, 67 parts of submicron scale YSZ powder and 18 parts of micron scale YSZ powder. Among them, the submicron YSZ powder includes 12 parts of submicron YSZ powder with a particle size of D50=0.15 μm, and 55 parts of submicron YSZ powder with a particle size of D50=0.4 μm.

[0061] In this embodiment, the dispersant is a coupling agent, the coupling agent is a silane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com