Method for preparing gradient-index film

A gradient refractive index and high refractive index technology, applied in the field of optical thin films, can solve problems such as interface damage performance, degradation, and instability of interface jump characteristics, and achieve the effect of simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

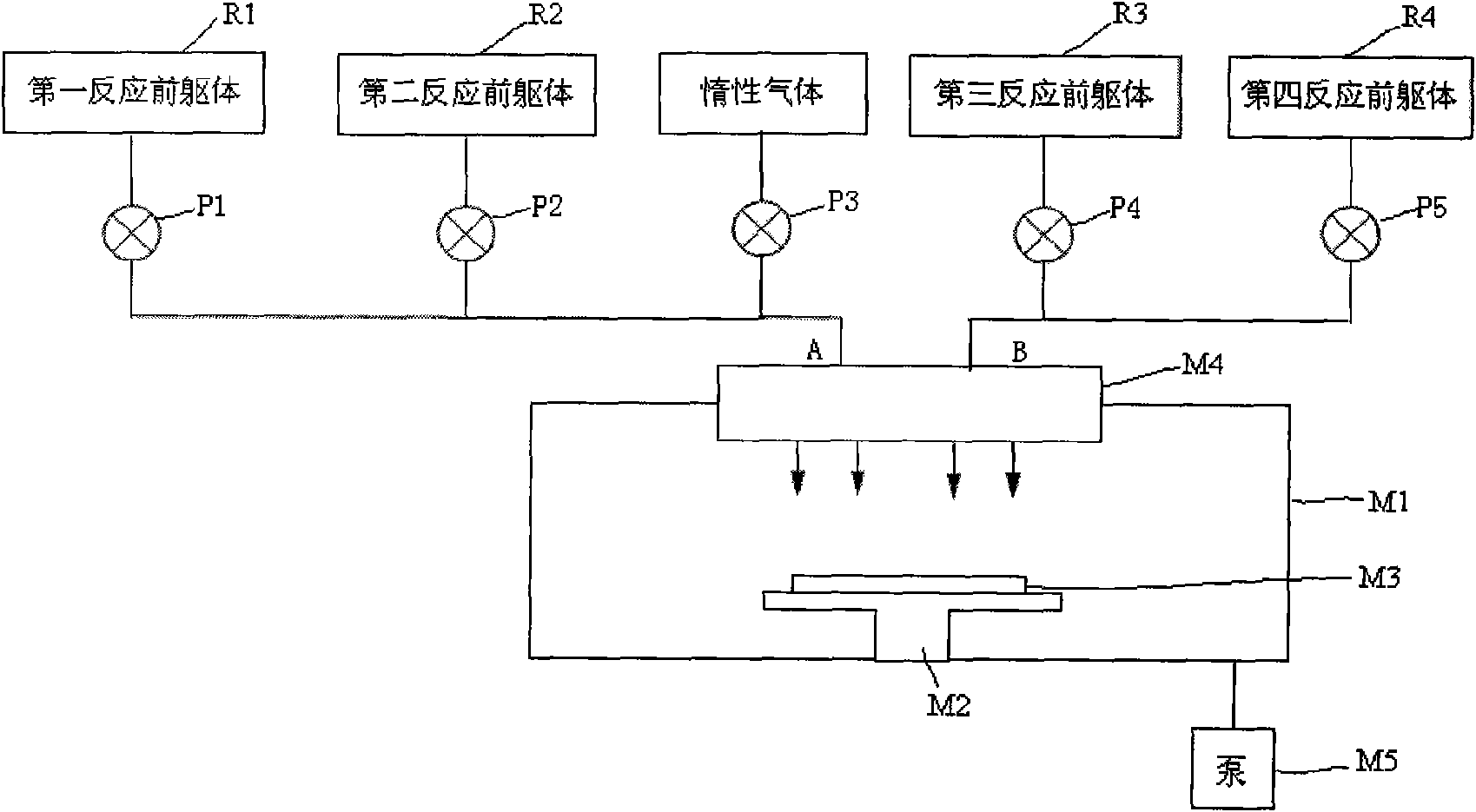

[0025] The preparation method for realizing the graded refractive index film comprises the following steps:

[0026] 1) Put the two low-refractive index material reaction precursors into the first reaction precursor container and the third reaction precursor container of the atomic layer deposition coating machine, and put the two high-refractive index material reaction precursors into the atomic layer deposition coating respectively a second reactive precursor container and a fourth reactive precursor container of the machine;

[0027] 2) Heating the substrate of the atomic layer deposition coating machine to 100°C-400°C, vacuuming to 0.1-1Torr, and turning on the atomic layer deposition coating machine;

[0028] 3) Open the first valve P1 and the third valve P3 of the atomic layer deposition coating machine, feed the first reaction precursor and the third reaction precursor respectively, deposit the low refractive index film layer for 1-100 cycles, and obtain the low refract...

Embodiment

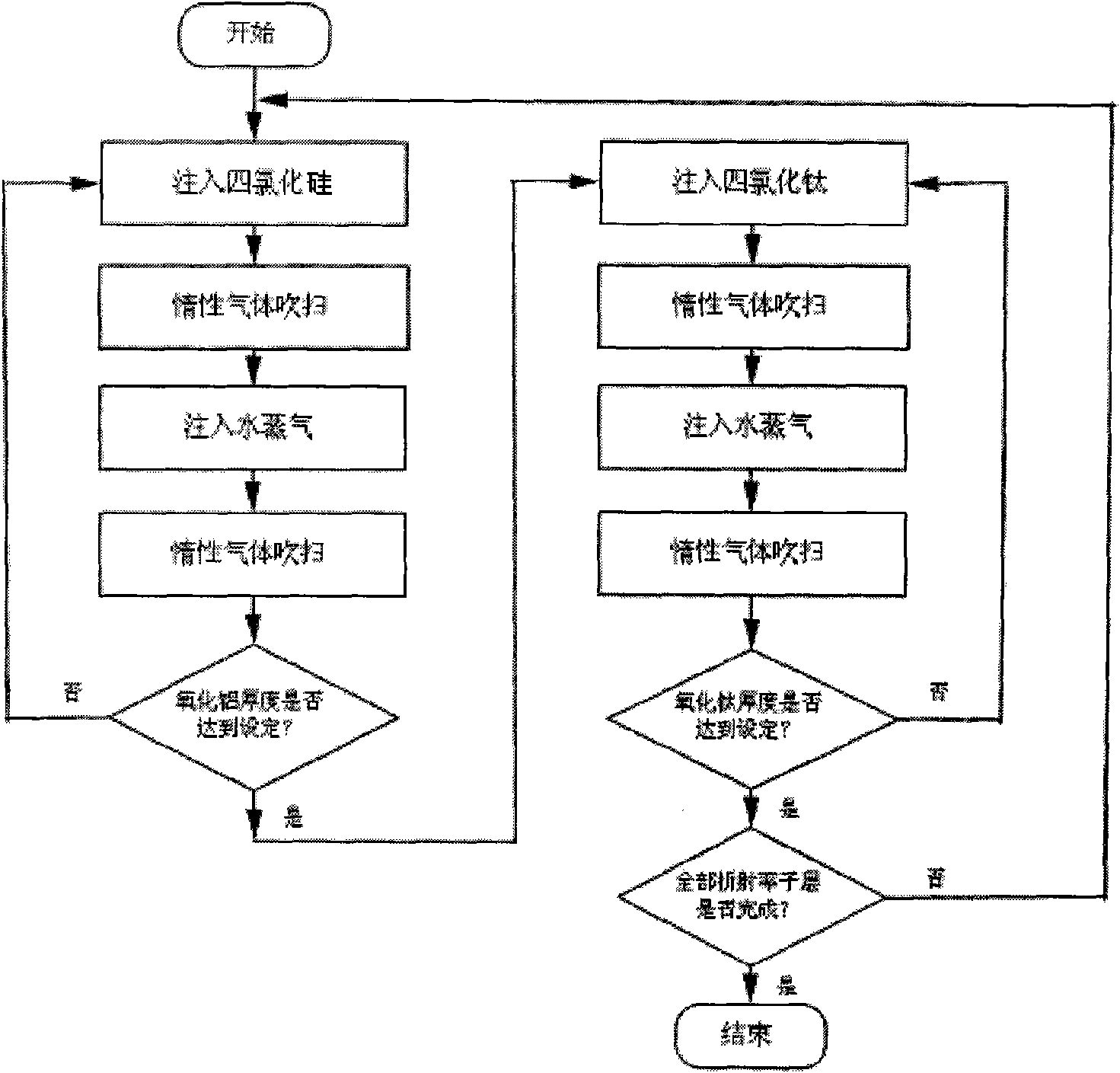

[0037] figure 2 It is the technological process of the method for realizing the gradient refractive index film layer of the present invention, specifically as follows:

[0038] The gradient refractive index film layer is prepared, and its refractive index is distributed according to a certain rule, which can be divided into multiple sub-layers, and then these sub-layers are replaced by a combination of extremely thin layers, so that the effect of gradient refractive index can be achieved in a wide wavelength range.

[0039]After loading the substrate into the reaction chamber M1, the treatment temperature of the reaction chamber is maintained between 100° C. and 400° C., preferably between 200° C. and 350° C., and the pressure of the reaction chamber is maintained between 0.1 and 350° C. by means of a heater. Between 1Torr. In successive steps, the process temperature and process pressure are maintained, but the temperature and pressure can be varied if desired, with differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com