Big data in process control systems

A process control system, process control technology, applied in the field of big data, can solve the problems of cumbersome, outdated troubleshooting during modeling, lengthy workflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

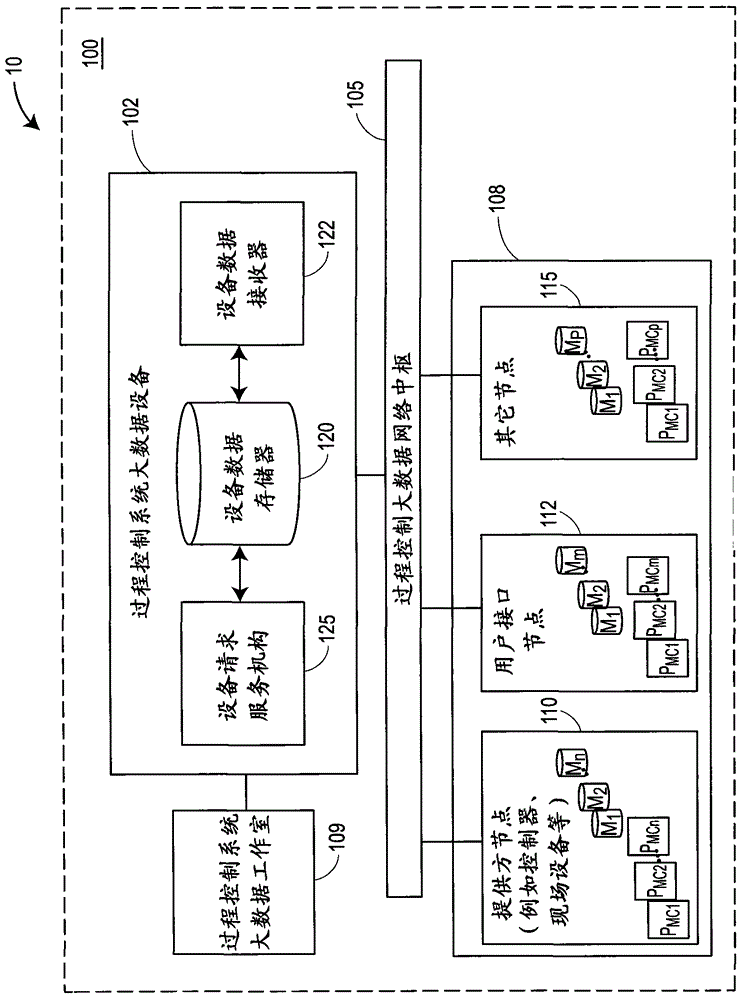

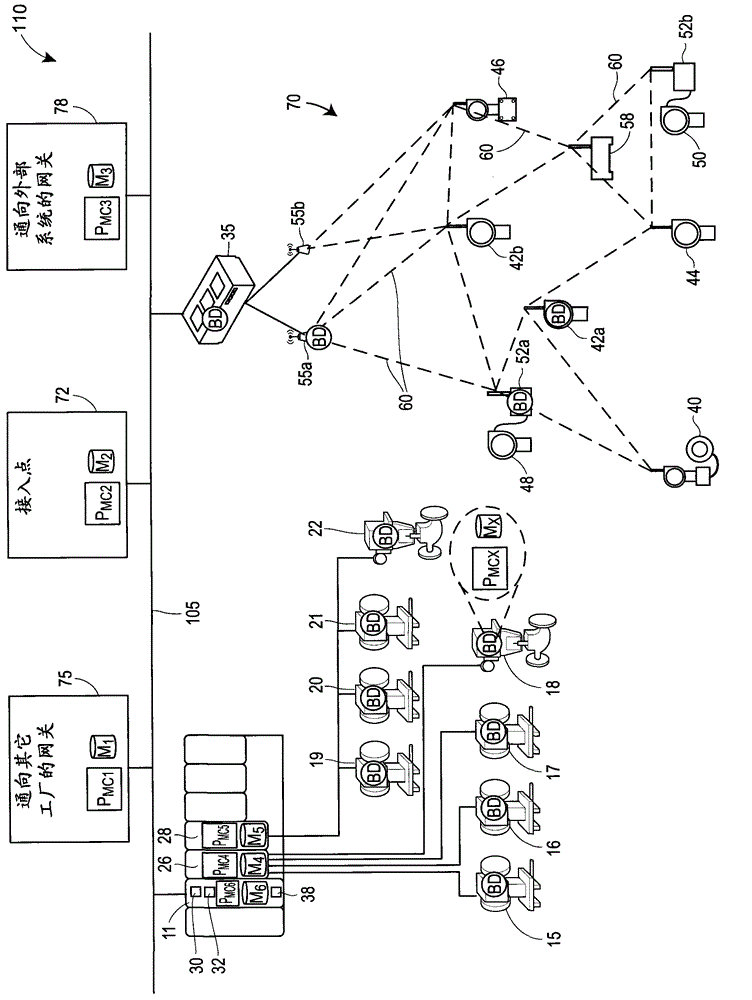

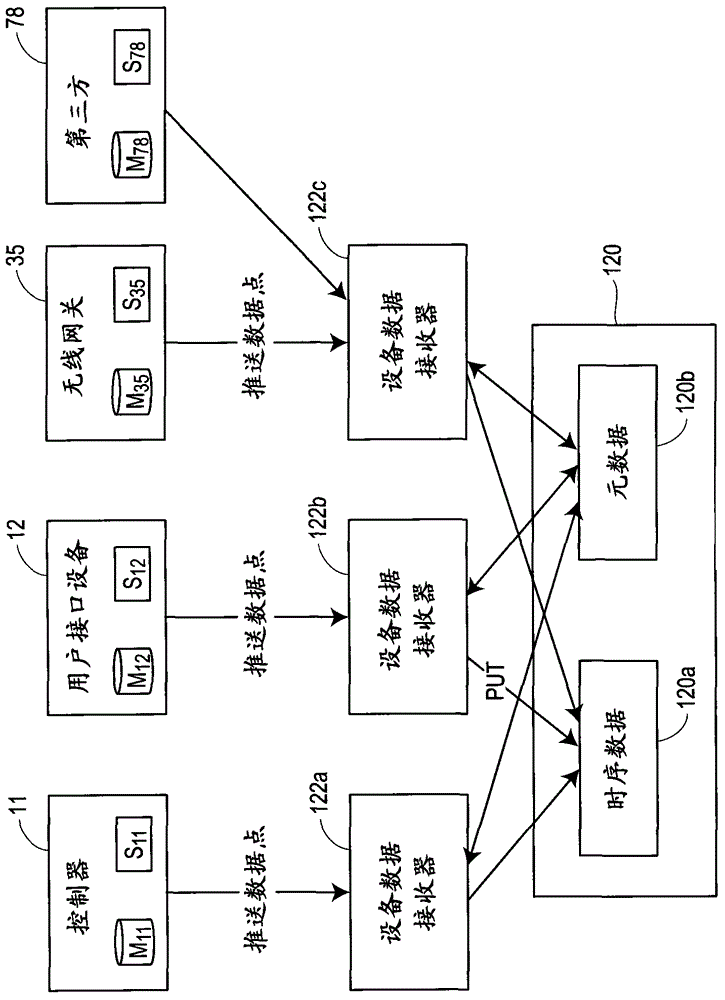

[0025] figure 1 is a block diagram of an example big data network 100 for a process plant or process control system 10 . The example process control system big data network 100 includes a process control system big data appliance or device 102 , a process control system big data network backbone 105 , and a plurality of nodes 108 communicatively connected to the backbone 105 . Process-related data, plant-related data, and other types of data may be collected and cached at multiple nodes 108, and may be delivered via network backbone 105 to process control system big data appliances or appliances 102 for long-term storage ( For example "historization") and processing. In one embodiment, at least some of the data may be communicated between nodes of the network 100 for real-time control of the process, for example.

[0026] Any type of data related to the process control system 10 can be collected and stored by the process control system big data appliance 102. In one embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com