Lithium ion battery nickel-cobalt-manganese ternary composite anode material and method for preparing precursor thereof

A lithium-ion battery and ternary composite technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve problems such as low specific capacity and potential safety hazards, and achieve the effects of uniform particle distribution, low cost, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] ①, raw material preparation

[0028] a, nickel-cobalt-manganese ion mixed solution, by Ni: Co: Mn=1: 1: 1 molar ratio is dissolved in hot water to make solution, the total concentration of three kinds of metal ions in the mixed solution is 1mo1 / L. The nickel salt is nickel nitrate, the manganese salt is manganese chloride, and the cobalt salt is cobalt acetate.

[0029] b, the preparation mass fraction is 25% NaOH solution and 20% ammonia solution.

[0030] c. Dissolve hydrogen peroxide in 4mol / L NaOH solution to prepare 1mol / L H 2 o 2 of NaOH solution.

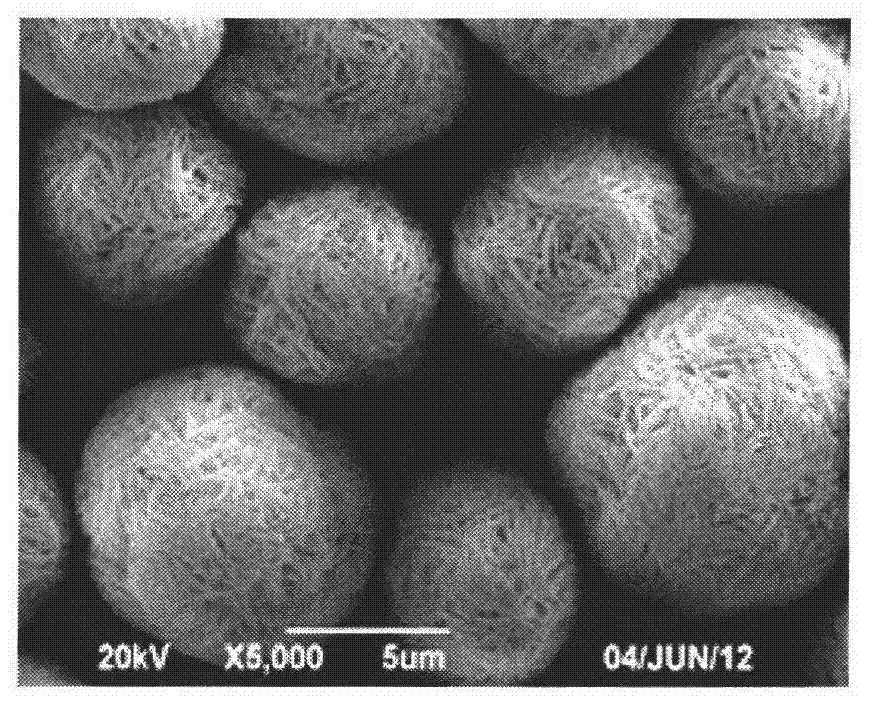

[0031] ②, Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 preparation of

[0032] a. Use pure water as the bottom liquid, raise the temperature to 40-50°C, start stirring, control the stirring speed at 150-180r / min, add ammonia water and sodium hydroxide, adjust the pH and pH of the bottom liquid, and maintain the alkalinity At 5-10g / L, the pH is controlled at 11-12.

[0033] b. Add nickel-cobalt-manganese ion mixture, ammonia s...

Embodiment 2

[0042] ①, raw material preparation

[0043] a, nickel-cobalt-manganese ion mixed solution, by Ni: Co: Mn=1: 1: 1 molar ratio is dissolved in hot water to make solution, the total concentration of three kinds of metal ions in the mixed solution is 3mol / L. The nickel salt is nickel chloride, the manganese salt is manganese nitrate, and the cobalt salt is cobalt sulfate.

[0044] b, the preparation mass fraction is 28% NaOH solution and 10% ammonia solution.

[0045] c. Dissolve hydrogen peroxide in 4mol / L NaOH solution to prepare 1.6mol / L H 2 o 2 of NaOH solution.

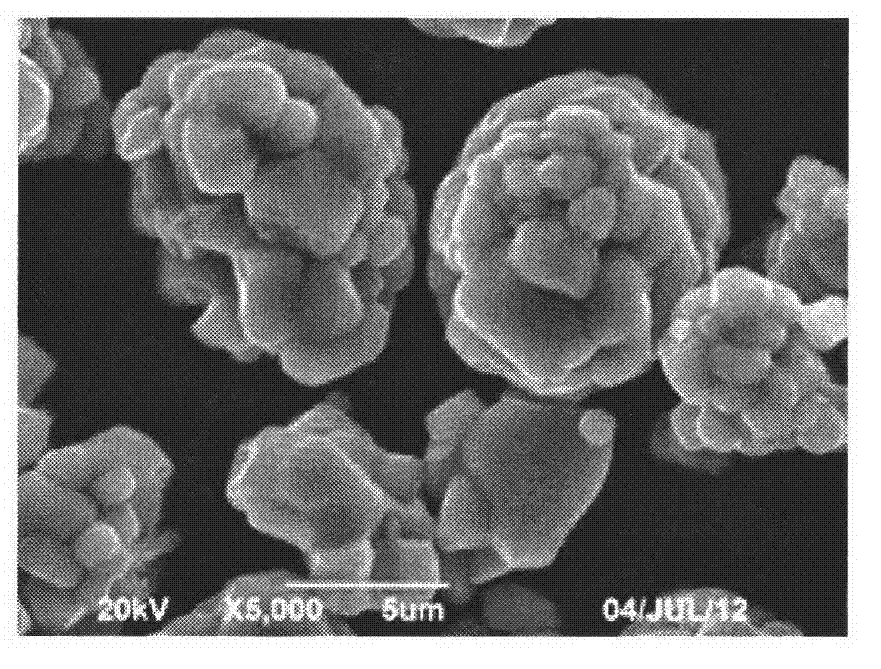

[0046] ②, Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 preparation of

[0047] a. Use pure water as the bottom liquid, raise the temperature to 50-60°C, start stirring, control the stirring speed at 120-160r / min, add ammonia water and sodium hydroxide, adjust the pH and pH of the bottom liquid, and maintain the pH At 10-15g / L, the pH is controlled at 10.5-11.

[0048] b. Add nickel-cobalt-manganese ion mixture, ammonia solu...

Embodiment 3

[0057] ①, raw material preparation

[0058] a, nickel-cobalt-manganese ion mixed solution, by Ni: Co: Mn=1: 1: 1 molar ratio is dissolved in hot water to make solution, the total concentration of three kinds of metal ions in the mixed solution is 1.5mol / L. The nickel salt is nickel sulfate, the manganese salt is manganese sulfate, and the cobalt salt is cobalt sulfate.

[0059] b, the preparation mass fraction is 22% NaOH solution and 12% ammonia solution.

[0060] c. Dissolve hydrogen peroxide in 4mol / L NaOH solution to prepare 0.6mol / L H 2 o 2 of NaOH solution.

[0061] ②, Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 preparation of

[0062] a. Use pure water as the bottom liquid, raise the temperature to 60-70°C, start stirring, control the stirring speed at 100-140r / min, add ammonia water and sodium hydroxide, adjust the alkalinity and pH of the bottom liquid, and maintain the alkalinity At 15-20g / L, the pH is controlled at 10-10.5.

[0063] b. Add nickel-cobalt-manganese ion mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com