Self-adaptive sliding-mode control method for liquid level control system based on Delta operator

A self-adaptive sliding mode and self-adaptive control technology, applied in the direction of self-adaptive control, liquid level control, general control system, etc., can solve the problems of poor control performance and instability of discrete system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings.

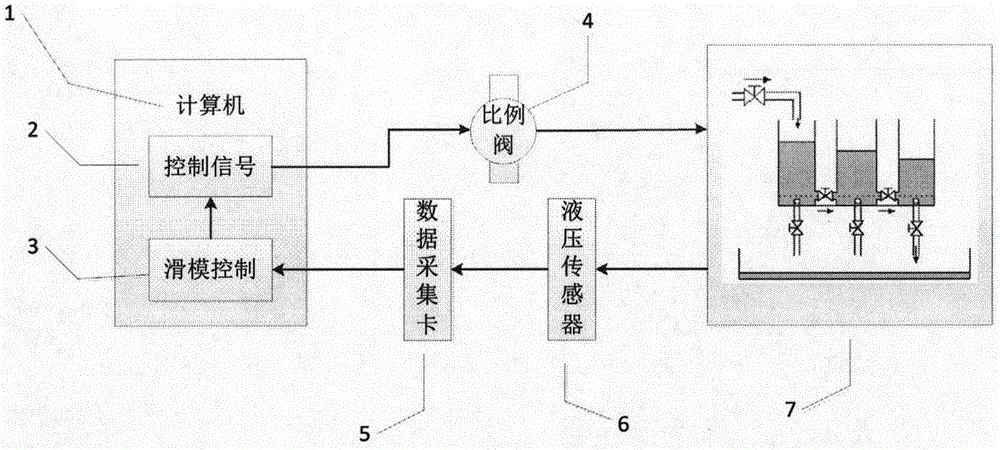

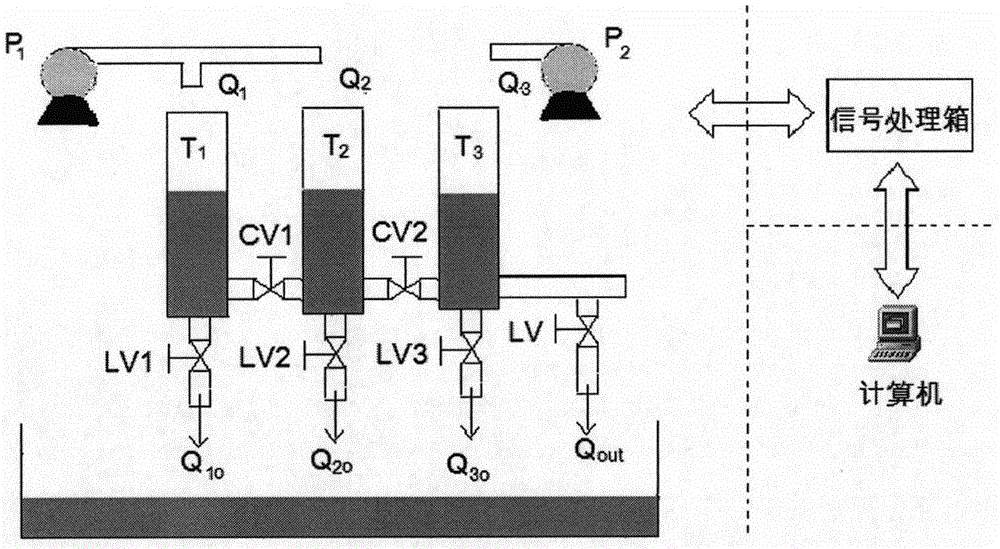

[0051] Such as figure 1 As shown, an adaptive sliding mode control method of the liquid level control system based on the Delta operator is implemented based on the selected device: the computer 1 as the host computer will implement the adaptive sliding mode algorithm 2 in the computer and send out the control signal 3 The data acquisition card 5 collects the voltage signal and transmits it to the computer; the three-capacity water tank 7 has a hydraulic pressure sensor 6 at the bottom of the water tank, and the water delivery pipeline is equipped with a proportional valve 4, and the valve ratio is controlled by the computer.

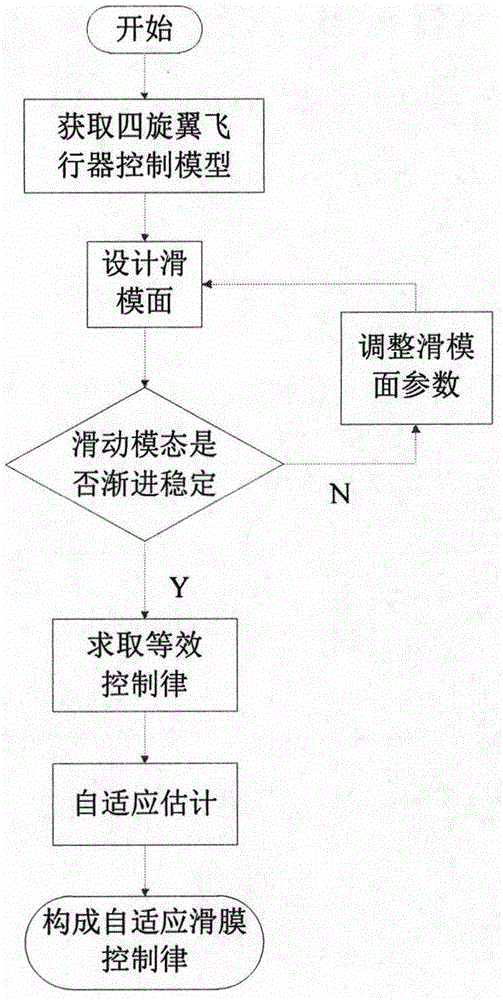

[0052] Such as figure 2 As shown, an adaptive sliding mode control method of liquid level control system based on Delta operator is characterized in that: considering the time-varying time-delay and modeling uncertainty in the process control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com